Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

I'M curious to see how your going to seal everything up...but actually, if you were to drape some thin metal accross the bottom section and have the runners run through it you should be in good shape.. giver' shit!

Leave a comment:

-

Connecting rods narrowed from the small end.

Pistons are zero deck height.

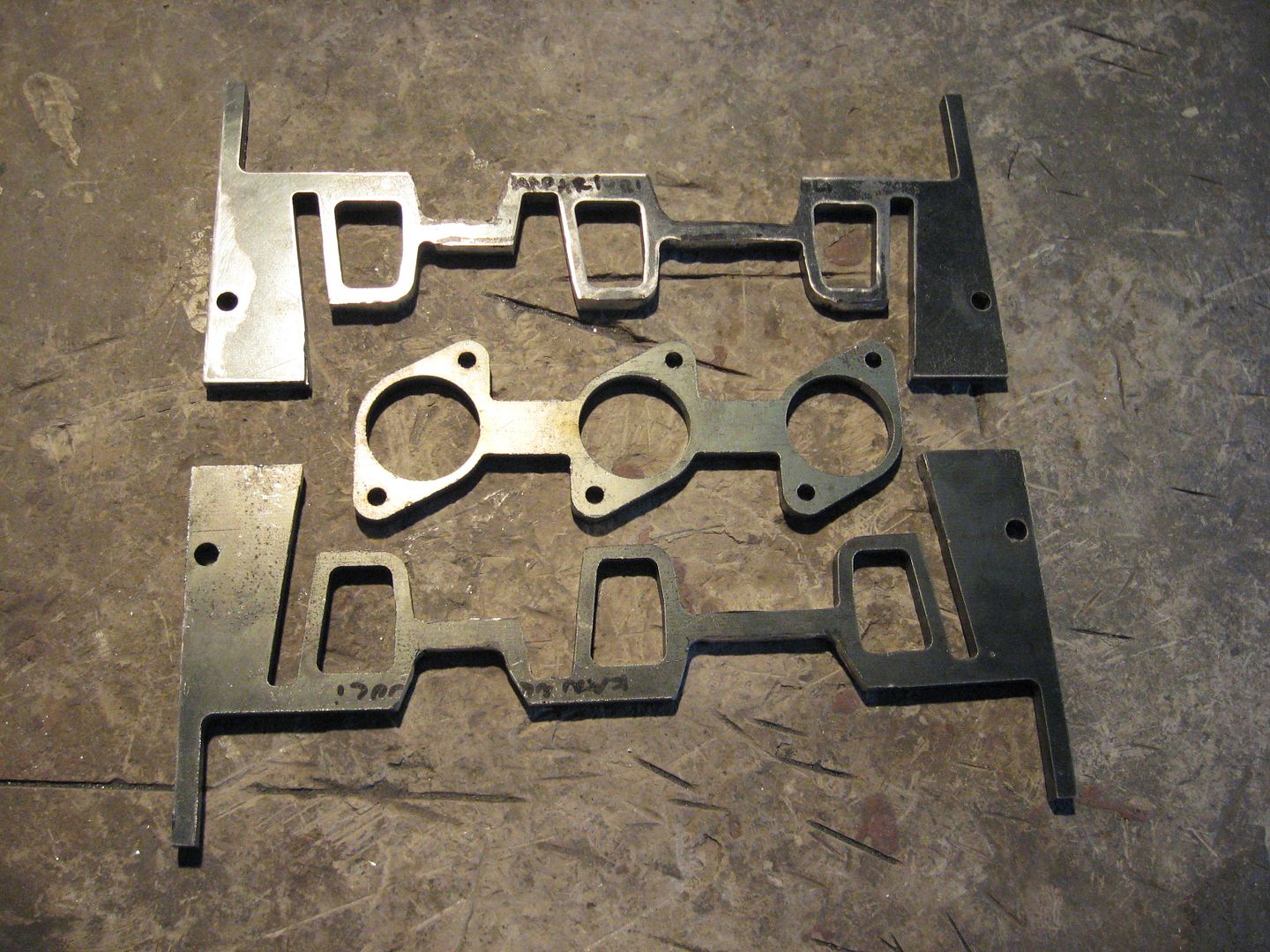

Laser cut flanges (10 mm) for custom intake manifold.

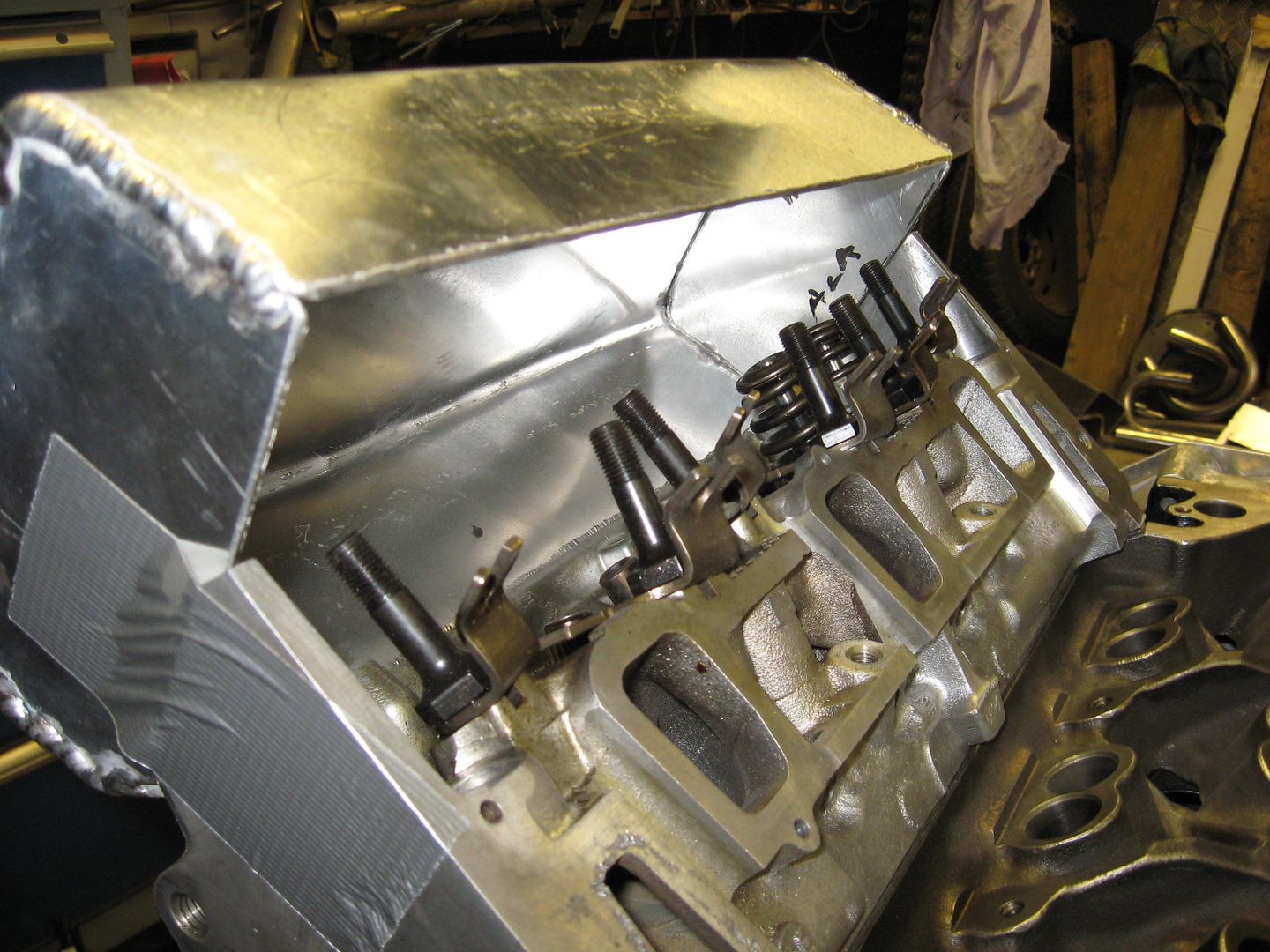

Well, thats a custom intake manifold allright.

WTF I hear you saying, but hold your horses.

Lets see what I can make out of it.

Last edited by veekuusi; 04-21-2012, 07:04 AM.

Last edited by veekuusi; 04-21-2012, 07:04 AM.

Leave a comment:

-

Allstar Performance crank mandrel kit for SBC.

Thats what I call custom XL valve covers.

Leaves you pretty much room for rockers and stud girdle.

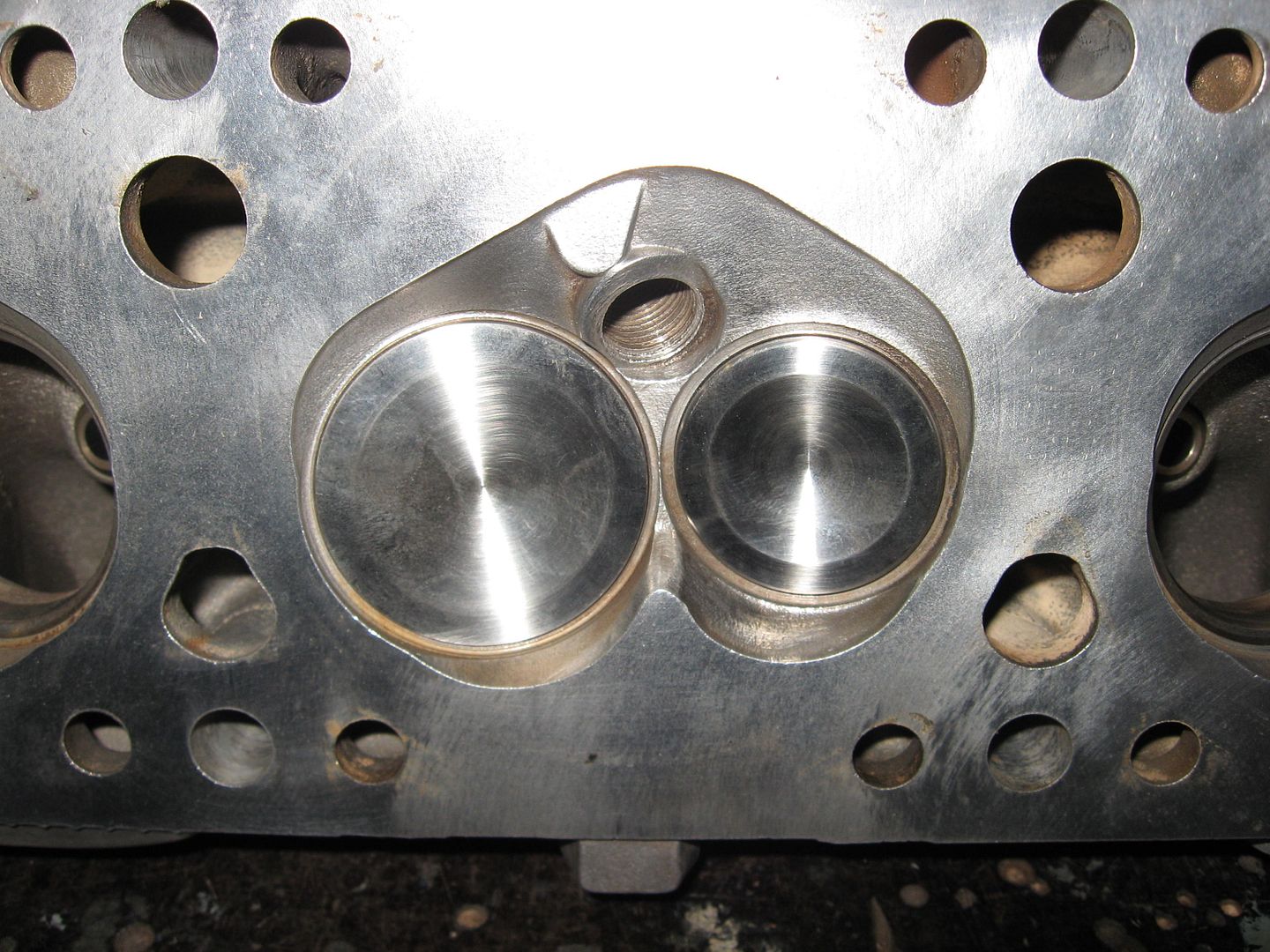

Manley stainless steel valves.

Intake 1.76"

exhaust 1.42"

3400 head

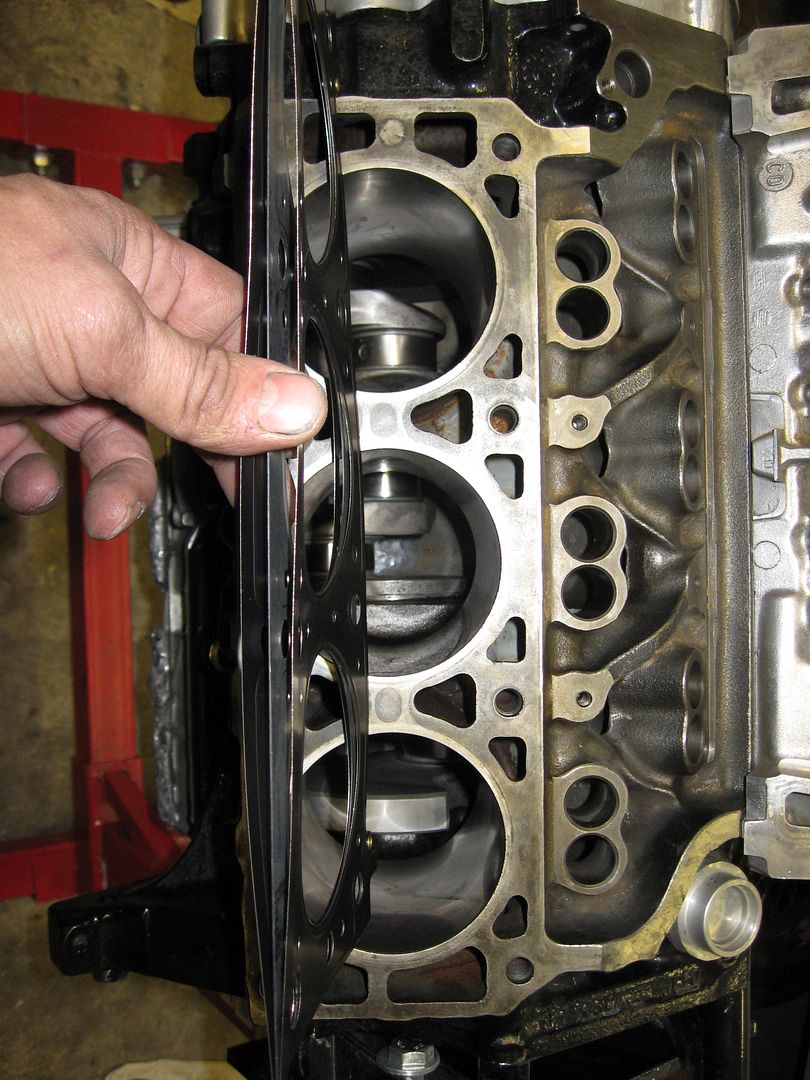

Cometic MLS head gaskets.

"Multi layer" , 3 layers of steel.

Last edited by veekuusi; 04-07-2012, 06:17 AM.

Last edited by veekuusi; 04-07-2012, 06:17 AM.

Leave a comment:

-

+1Originally posted by betterthanyou View PostOne down side to our chains is the length of them compared to a small or big block. On those engines the gears almost touch. On ours there is enough room for a damper. What would be an awesome addition is putting in a spring loaded tensioner on the slack side of the chain to prevent any whipping. If this engine is going to live at 8000 RPM then I would look into a belt drive.

Leave a comment:

-

One down side to our chains is the length of them compared to a small or big block. On those engines the gears almost touch. On ours there is enough room for a damper. What would be an awesome addition is putting in a spring loaded tensioner on the slack side of the chain to prevent any whipping. If this engine is going to live at 8000 RPM then I would look into a belt drive.

Leave a comment:

-

I was just wondering whether Cloyes makes a "True" Double Roller Timing Set that could withstand such high RPM at Eight Grand. Even with the amazing conversion from a stiff, friction heavy high lift hydraulic flat tappet and camshaft set up over to this radical, eliptical, real roller camshaft design here...it would seem that having the Cloyes solution in this engine would go very far at seriously reducing parasitic friction from all that hard grinding the normal Stock Timing Set makes. I've never seen any of these timing sets come off of the front of a used or high mileage 660 engine without displaying the deep grinding wear grooves that occur when that style of hard gripping chain is driven by an equally resistant crankshaft gear.

Leave a comment:

-

Lighter, and the ramp up rate on his cam is higher than the XFI hydraulics roller lobes I sell in the race cams. He needs solid roller for sure.

Leave a comment:

-

Lol thats a good use for old Ford parts. Nice call on the torque plate. It pays off big time when trying to get an accurate bore.

Leave a comment:

-

Not much has happened here for 2 weeks.

I have been in bed, since I have been sick.

Yesterday I made a torque plate.

It is bolted to the block while drilling and honing.

First over bore .010"

Diamond recommends piston to wall clearance .0045".

"Big boys" told me that it is too much, but maybe I trust what it says

in the piston spec card.

The machine shop will also align hone the main bore.

Because of the use of ARP main studs and increased clamping force on the caps.

The spacers on the head bolts are wrist pins.

They are from Ford, hope that is not going to cause reject in Chevy engine.

Leave a comment:

-

QFTT! thats ah good idea actuallyOriginally posted by betterthanyou View PostOne other thing I would suggest for your dry sump modifications is to plug the oil gallery in the oil filter mount location or remove the main cap and plug the galley there with a pipe plug and reinstall the cap.

Also since you don't need the lower rad hose you can machine that section off the timing cover and remove that cover plate and weld in hose fittings to the large coolant ports leading to the block and plumb your remote pump into them. It would better ensure even water distribution. Plus you wont have to worry about water leaks at the plate.

Leave a comment:

-

One other thing I would suggest for your dry sump modifications is to plug the oil gallery in the oil filter mount location or remove the main cap and plug the galley there with a pipe plug and reinstall the cap.

Also since you don't need the lower rad hose you can machine that section off the timing cover and remove that cover plate and weld in hose fittings to the large coolant ports leading to the block and plumb your remote pump into them. It would better ensure even water distribution. Plus you wont have to worry about water leaks at the plate.

Leave a comment:

-

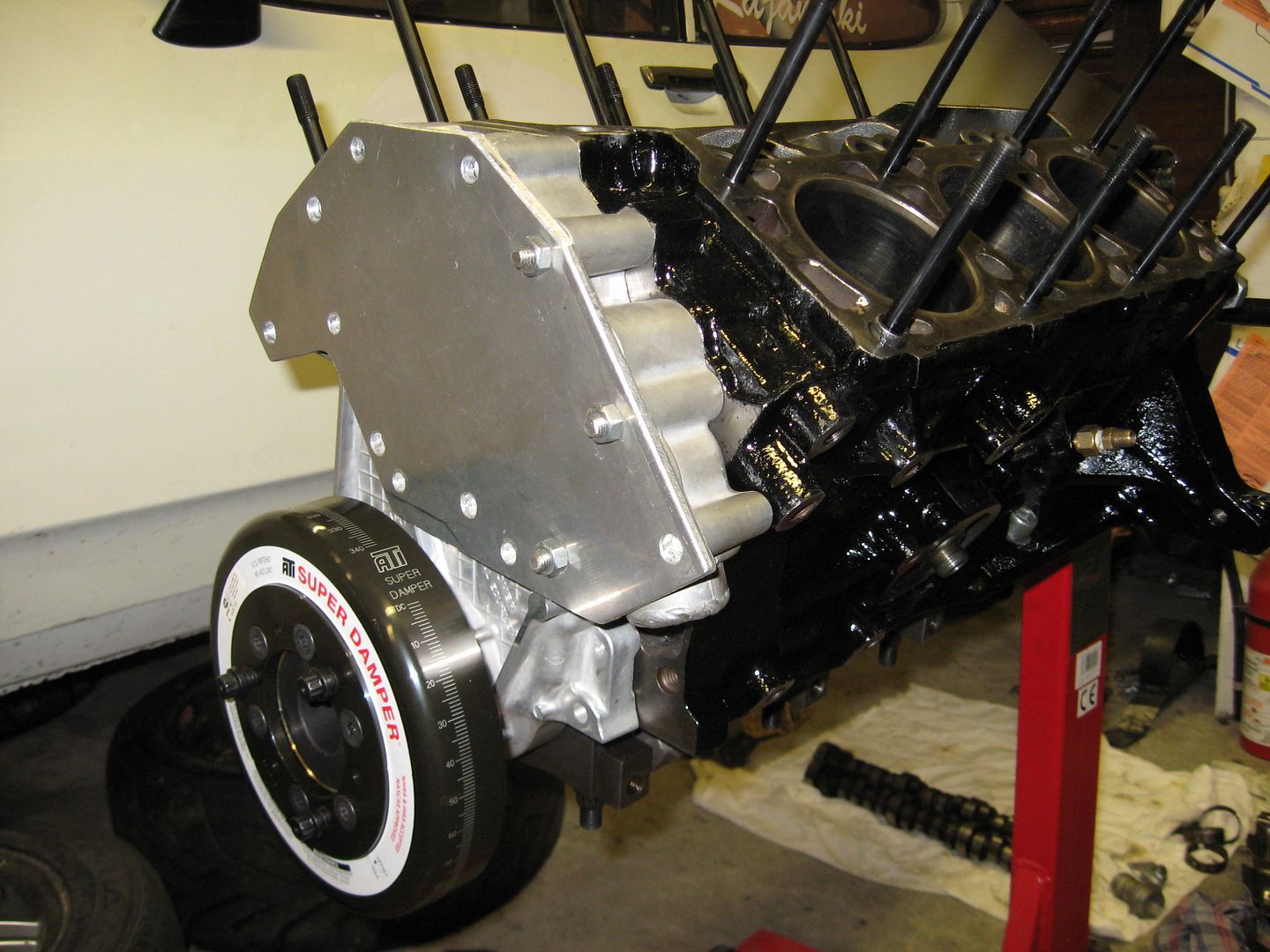

The mail man is tired of carrying my packages.

He said , he is going to quit.

Today came one more delivery.

ATI damper.

It is for Camaro, 60 degree V6 RWD application.

It has longer hub, so no problem to use it with RWD timing cover.

Leave a comment:

-

The pistons were supposed to be based on the 3400 pistons but for a different crank and bore. I spent a good amount of time with Diamond to make sure these were made properly and it still didn't happen

Leave a comment:

Leave a comment: