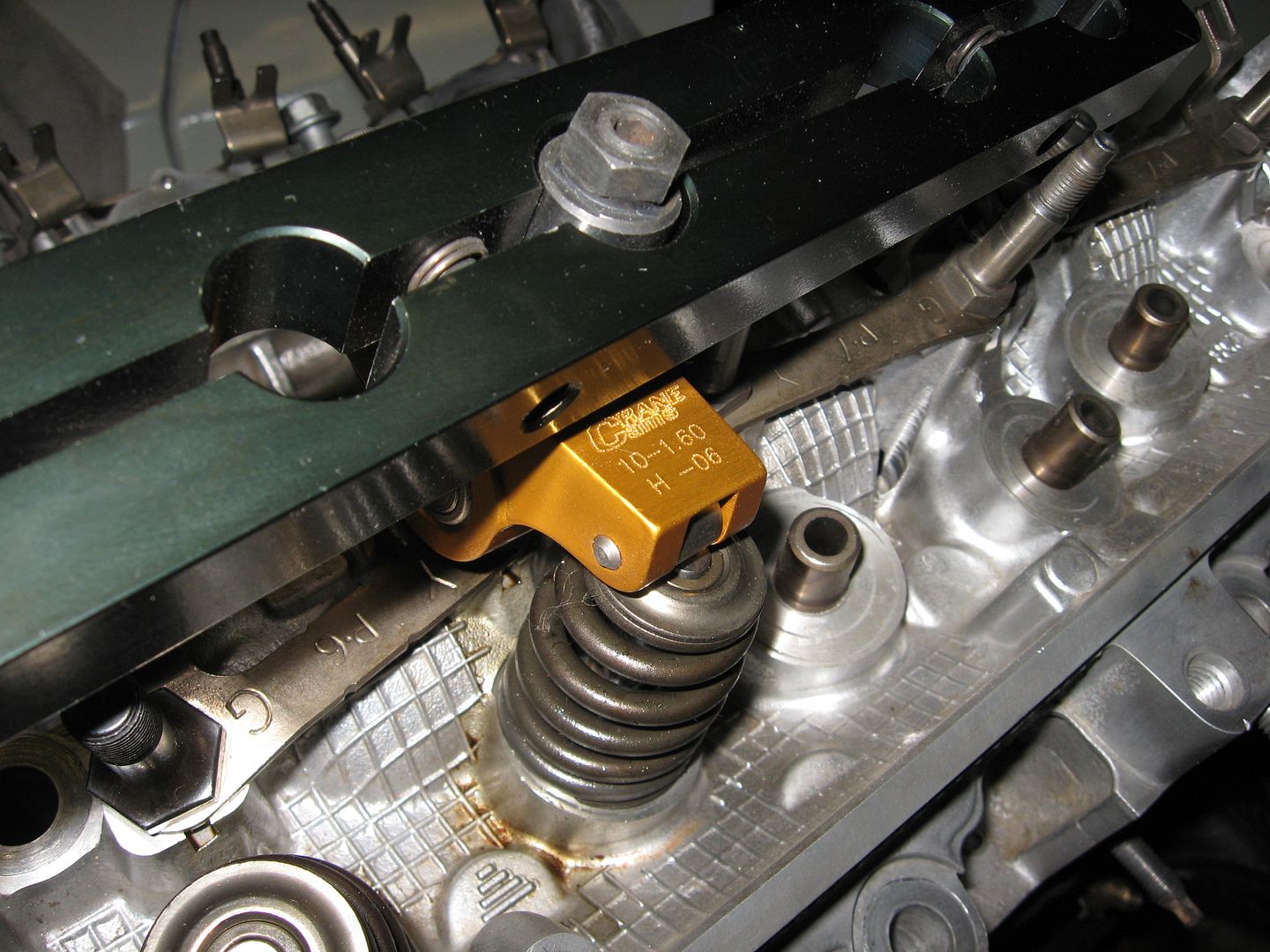

I am only familiar with shorter hall sensors.

You need a longer one with this.

And other issue with the damper.

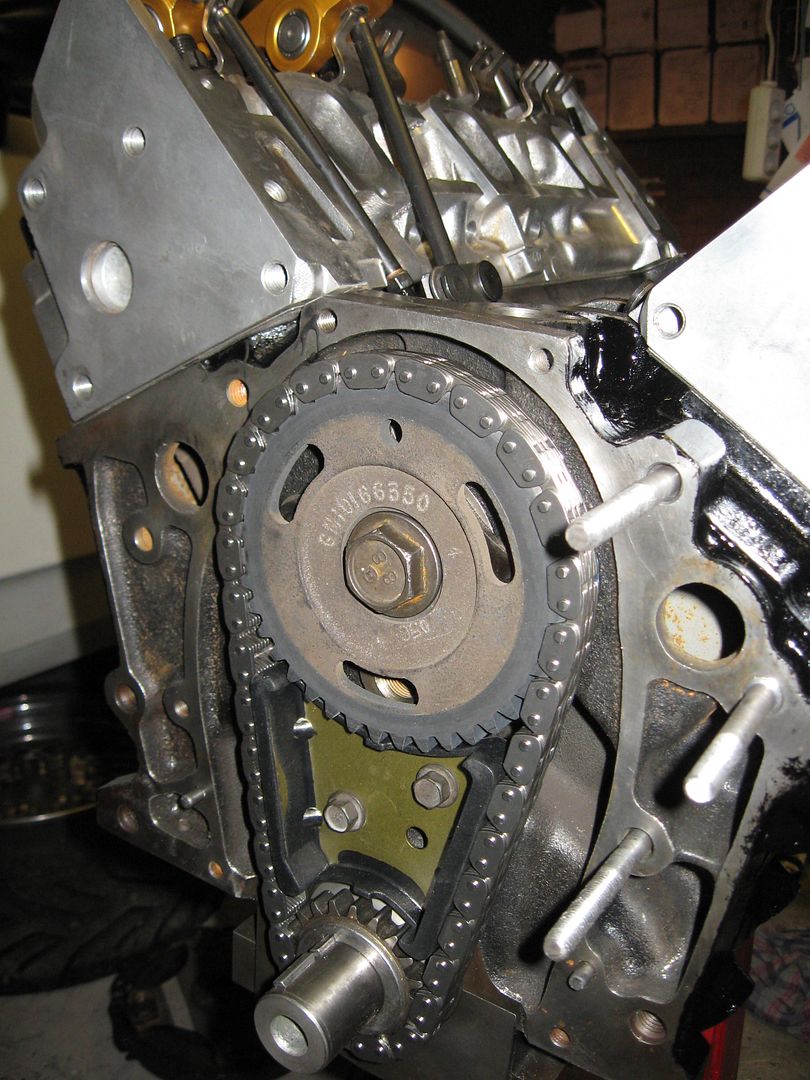

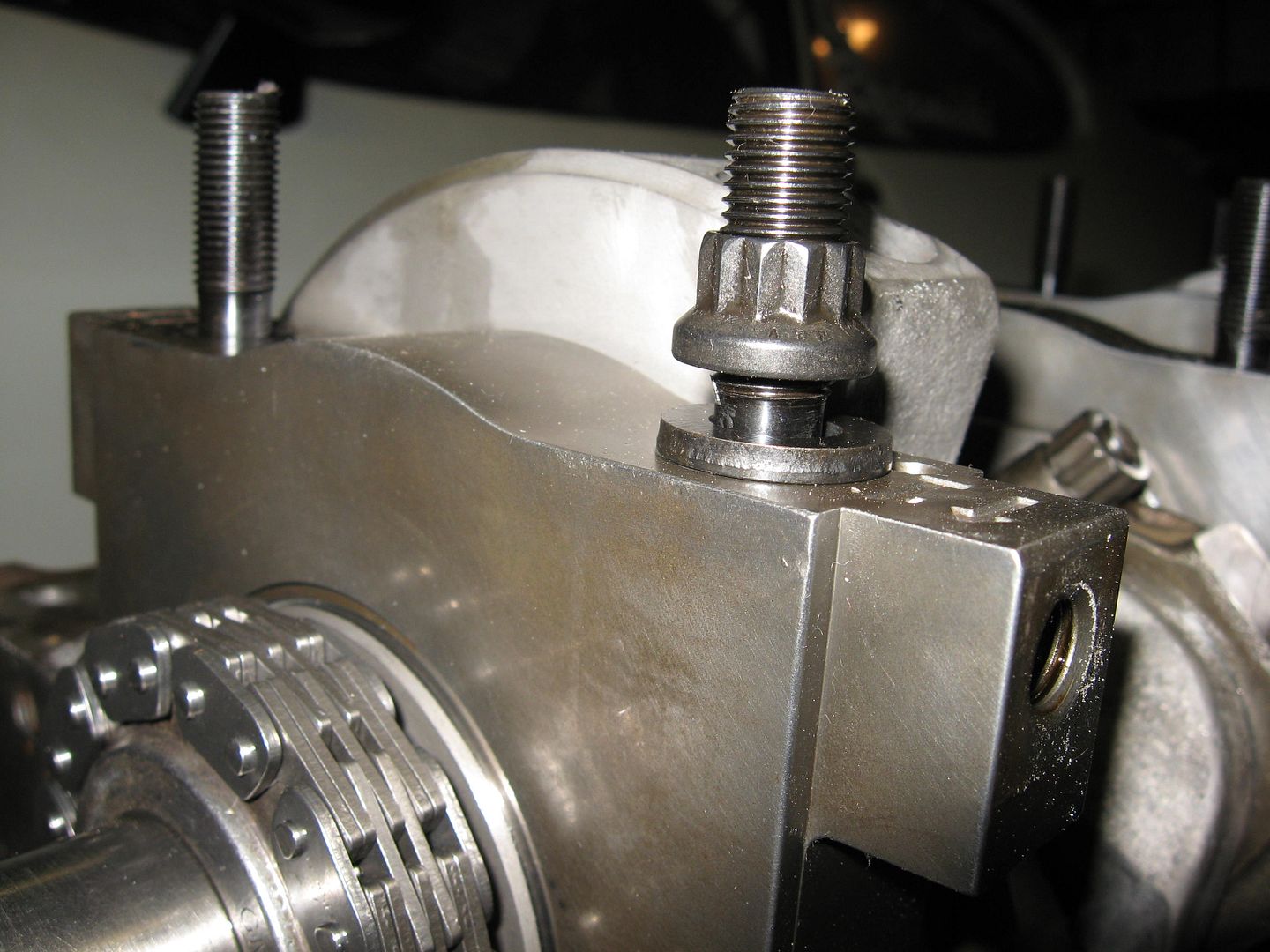

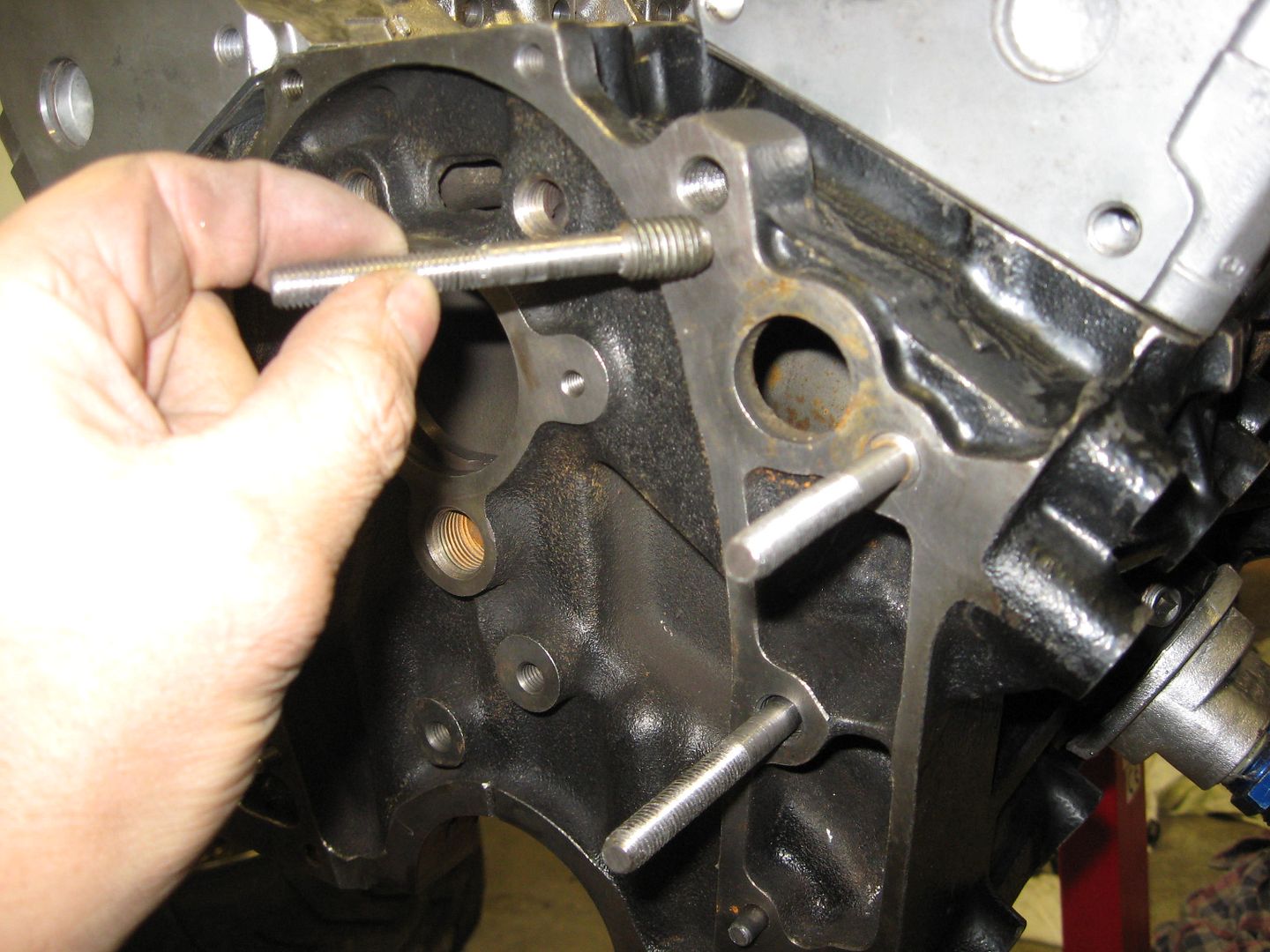

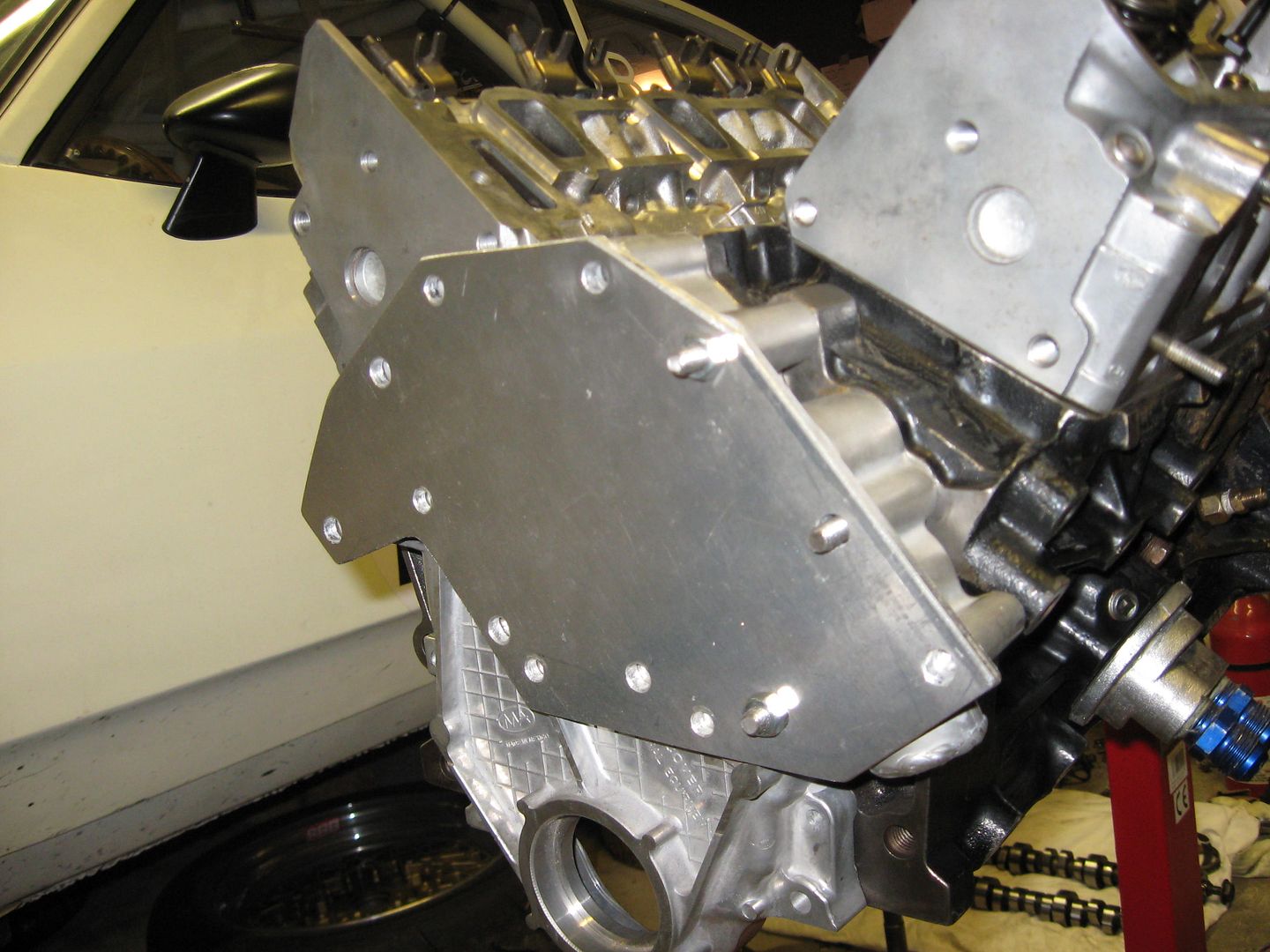

I can not use the FWD damper with the RWD timing cover.

The hub is not long enough.

The RWD timing cover is some 10 mm thicker , so the damper do not go to the bottom,

but it contacts with the timing cover.

I was planning to buy ATI damper, sent email to them and asked what damper would

be good to me. I guess they do not bother answers to me.I have not got any answer.

Are any of you familiar with this issue?

Leave a comment: