Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

The problem is you are sharing 50mm between two cylinders that are firing consecutively, so you are actually sharing the carb as a small plenum. The reason the stock engine can use such a small throttle is because there is a common plenum behind the throttle to store air.

50mm throttle will flow 260.64cfm, but since the cylinders are firing on after the other there is no storage of air at the back of the throttle plate in your carb. This means each cylinder theoretically is only getting 130cfm.

Comparing to a 4 barrel carb is like comparing the 52mm throttle with a planum behind it because the 4 barrels are feeding more than one (or two)cylinders.

The optimum size for the 60 degree v6 for 6 throttles is somewhere in the 38mm range (six 38mm throttles).

I still feel feeding the pairs with 50mm with no plenum may be too small.

Curious to see what happens when the ignition is corrected.

Leave a comment:

-

Thanks for your speculation.

Stock 3100 = single 52 mm throttle body

Stock 3400 = single 56 mm throttle body

And Wot-Tech sells a 65 mm throttle body for tune up applications for 3400 V6 engine.

And I am having 3 x 50 mm carb (that is 3 times 50 mm),

so I am pretty sure the engine gets enough air through the carb.

Because my engine is only 2800 cc.

It would be nice to know the CFM of my carb,

but when you look the throttle body of a 390 (Holley) or even a 600 CFM carb,

the throttle butterfly is very small, 30 -40 mm I believe (4 x 40 mm ?).

My electricity expert is in "deep coma".

Too many beers .

I phoned him, and he said he could check the ignition at earliest next week.

So I have to wait, I must be 100 % sure the ignition is allright , before I do anything else.

Leave a comment:

-

Sent from my HTC One X using Tapatalk 2Originally posted by veekuusi View PostIt is 3 x 50 mm carburetor.

Leave a comment:

-

I agree here, that way each carb will have a smoother pull instead of pulses.Originally posted by bob442 View PostMaybe this would sound stupid, but wouldn't it be ideal to have most upposing cylinders on the cam sucking from the same carb? It would make for a tall intake but that would be beneficial for higher rpms

Leave a comment:

-

Maybe this would sound stupid, but wouldn't it be ideal to have most upposing cylinders on the cam sucking from the same carb? It would make for a tall intake but that would be beneficial for higher rpms

Leave a comment:

-

Those carbs might be too small. That site shows them using 6 on a 3.8 liter engine.

Leave a comment:

-

Originally posted by dskopek View PostIf you are feeding 2 cyl with each barrel of the carb you should see a gain in HP if you run a plenum under the carb so all 6 cylinders can draw air and fuel from all 3 barrels of the carb you have to use. Think of a small tunnel ram or single plane intake manifold. With a dual plane manifold you divide the carb so half of the barrels feed half of the motor, Most dual planes boost low to mid range and give up upper rpm hp. On the single plane and tunnel ram type you have a common plenum under the carb/carbs so all cyl can pull air from all barrels. They give up bottom end and some midrange for higher rpm gains. This also helps a little if the carb is a little bit small for peak power becouse the plenum holds a volume of air/fuel mix. Do you know what is the CFM of the carb you are using?

There is no information about the CFM of the PMO carb I am using.

I used to have a custom plenum intake with my old Ford engine with the same

PMO carb I am using now.You can read the hp in the dyno sheet.

When I made the plenum intake to the Ford engine, the expectations were high,

but the result was not good.

That is why I made this 1 barrel to 2 cyl intake to the new GM engine, hoping it would work better.

I even have had a 390 cfm Holley and Offenhauser Dual Plane intake in the

Ford V6 engine.

But I had to discontinue using it because there was problems with detonation.

The air fuel ratio was not ideal on all 6 cylinders.

The mixture was too rich in "central" cylinders and too lean in "outer" cylinders,

and the outer cylinders were in trouble.

Thats why I figured the 1 barrel to 2 cylinders would give good air fuel ratio to

all cylinders.Last edited by veekuusi; 10-29-2012, 01:46 PM.

Leave a comment:

-

Yea, that would be nice if somebody made something like that for these engines. Nice straight shots to the valves,some plenum volume for rpm and able to use off the shelf carbs to get the airflow you need.

Leave a comment:

-

I think the intake is ok for what he's doing, i bet the low power is just from the advance issues.

It would be nice to use an intake like a Victor Jr and just feed it with a single 600 cfm mechanical secondary though.

Leave a comment:

-

If you are feeding 2 cyl with each barrel of the carb you should see a gain in HP if you run a plenum under the carb so all 6 cylinders can draw air and fuel from all 3 barrels of the carb you have to use. Think of a small tunnel ram or single plane intake manifold. With a dual plane manifold you divide the carb so half of the barrels feed half of the motor, Most dual planes boost low to mid range and give up upper rpm hp. On the single plane and tunnel ram type you have a common plenum under the carb/carbs so all cyl can pull air from all barrels. They give up bottom end and some midrange for higher rpm gains. This also helps a little if the carb is a little bit small for peak power becouse the plenum holds a volume of air/fuel mix. Do you know what is the CFM of the carb you are using?

Leave a comment:

-

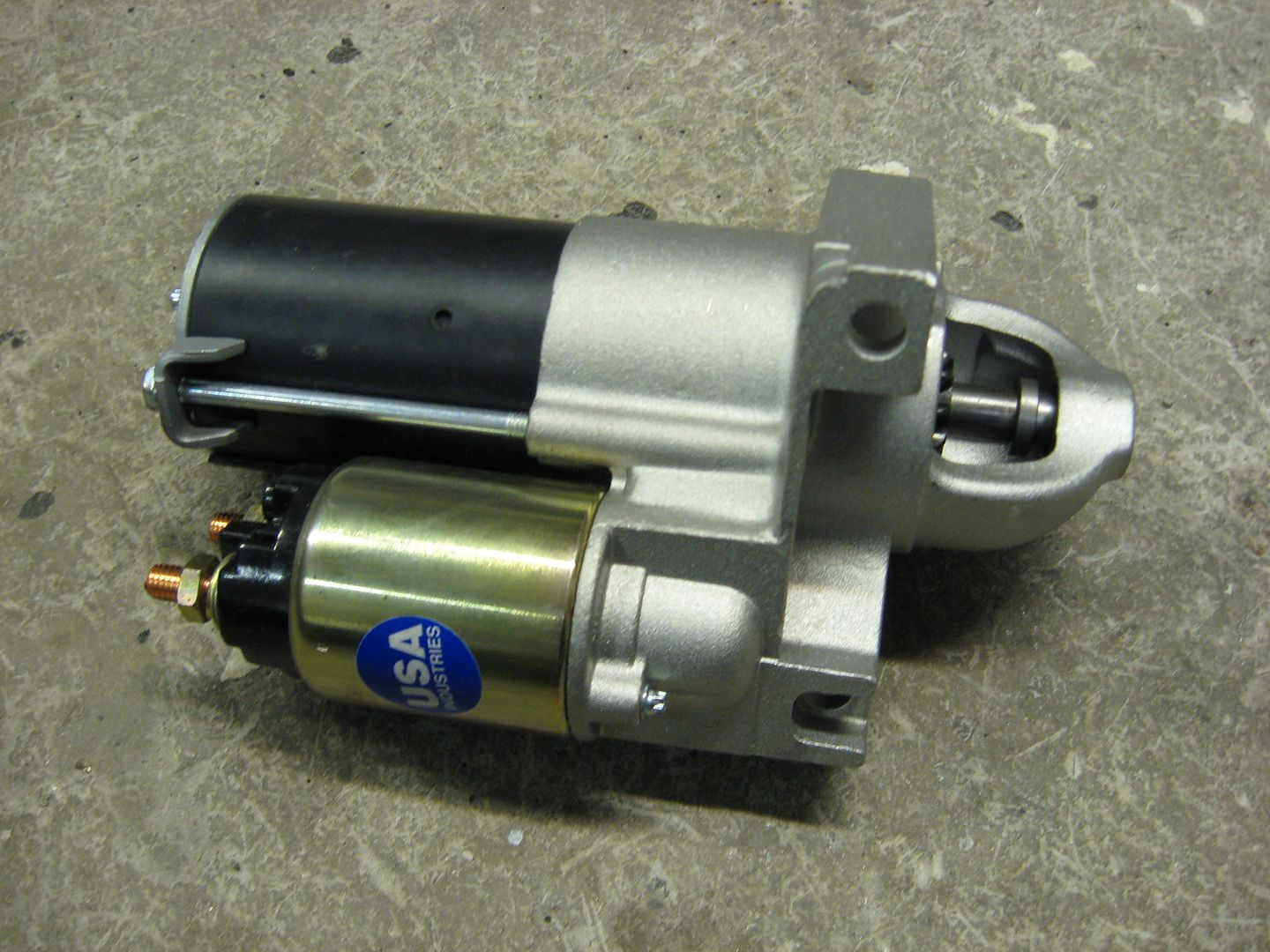

I bought a new starter. 2000 + 3400 V6.

There might be some kind of planetary gear system in it.

Try to assemble it this coming week and see how it works.

All the spark plugs in my engine seems okay after the dyno session.

But the problem can be in the ignition system.

The firing spark is perhaps not working properly after 5000 rpm.

When we looked the ignition with a strobo light, the ignition mark in the damper

starts to move very much after 5000 rpm. It shakes some half inch .

That means the firing time changes very much.

I have to check the ignition first thing.

I need an expert with a oscilloscope and everything.

The target is still 8000 rpm with this engine.Last edited by veekuusi; 10-29-2012, 09:27 AM.

Leave a comment:

-

is there a regulation size on the carbs? I think that might be part of what is holding you back up top, but it's tough to say. install a map sensor or vacuum gauge and see houw close you get to atmosphere at WOT.

Leave a comment:

Leave a comment: