Originally posted by whitelightnin04MC

View Post

Announcement

Collapse

No announcement yet.

Porting suggestions/pics for 3x00 heads

Collapse

X

-

1 5/8" worked perfect.. although beating the ends into a D shape wasn't the most fun i've ever had.. that's why i used round ports on the last set i built.

Comment

-

Sounds like when I beat a 2.5" pipe to fit my t3 turbo flange. I tacked it, beat it, tacked it, beat it etc etc. Came out nice, though.Originally posted by Superdave View Post1 5/8" worked perfect.. although beating the ends into a D shape wasn't the most fun i've ever had.. that's why i used round ports on the last set i built.

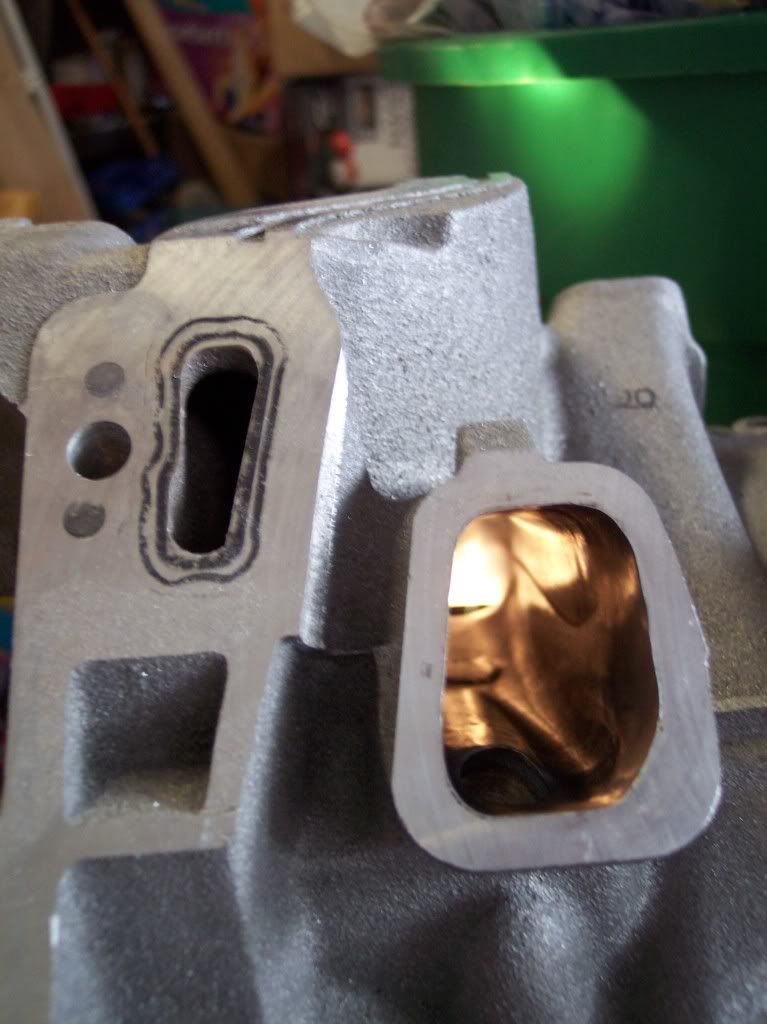

Look at the shiney ...

...

3400-95-modified thanks for the flapper suggestion! I used 80, 120, then a cotton buffing wheel. Probably can skip the 80 on the rest because the stone does a nice job.

I also think I am going to try and use a dowel, dill a hole in the end, and glue a Dremmel bit in it, so I can put in a drill and get the entire runner length as nice as I can.Last edited by ForcedFirebird; 09-25-2007, 05:56 PM.

Comment

-

I didn't need to drop the RPM. My problem was that, with the big bulky trigger, you still had to hold it down all the time and that kind of limited how I could hold the grinder. With the dremel, I just set the speed switch and went to town.Originally posted by ikessky View PostI just use an air regulator to drop the RPM of the die grinder. That way, I can just hold the trigger all the way down rather than trying to feather it.

Comment

-

smoother than mine... Then again I'm not planning on boosting

Got Lope?

3500 Build, Comp XFI Cam 218/230 .050 dur .570/.568 lift 113LSA

Fully Balanced, Ported, 3 Angle Valve Job, 65mm TCE TB, S&S Headers.

Stage-1 Raybestos/Alto 4t60e-HD, EP LSD, 3.69FDR

12.61@105 Epping NH Oct 2015 Nitrous 100shot (melted plugs) 13.58@98.8 N/A 3200LBS

Comment

-

Issac: Fangu! I was going to smooth the casting marks too, but the block will be here Thursday and I'm trying to make the Southern V6 Clash in March (N/A). I think they will be just fine

I was going to smooth the casting marks too, but the block will be here Thursday and I'm trying to make the Southern V6 Clash in March (N/A). I think they will be just fine  .

.

Modified: I will be N/A and posing dyno results before returning the boost. 11:1 compression is a little much for a turbo, so until I get the 3400 pistons I'm working on, this will be all motor.

Comment

-

Nope, as I stated earlier I will polish it to the injectors.Originally posted by SappySE107 View PostI wouldn't polish it leading from the lower to the head.

80 grit rough enough after?

Comment

-

Actually I was using 120 to finish the runners, then buffing them with a cotton buffer and red compound to get the mirror finish. Perfect, I'll just leave them at 120. I thought 120 would be a little too smooth to prevent fuel coagulation.Originally posted by SappySE107 View PostI use 120 so yeah, 80 is perfectly fine.

Comment

-

Yeah you'll be fine. I wouldn't worry about the casting seam too much. In my 97 3400 plenum it was visible but didn't stick out or feel like a bump to the touch so I left it alone. The 94 3100 casting was waaay rougher with irregular square notches on the top round ports (???) and the cast was super rough. The 97 3400 was very smooth inside, no rough sand feel at all.

sigpic

Yeah you'll be fine. I wouldn't worry about the casting seam too much. In my 97 3400 plenum it was visible but didn't stick out or feel like a bump to the touch so I left it alone. The 94 3100 casting was waaay rougher with irregular square notches on the top round ports (???) and the cast was super rough. The 97 3400 was very smooth inside, no rough sand feel at all.

sigpic New 2010 project (click image)

New 2010 project (click image)

1994 3100 BERETTA. 200,000+ miles

16.0 1/4 mile when stock. Now ???

Original L82 Longblock with LA1, LX9, LX5 parts

Manifold-back 2.5" SS Mandrel Exhaust. Hardware is SS too.

Comment

Comment