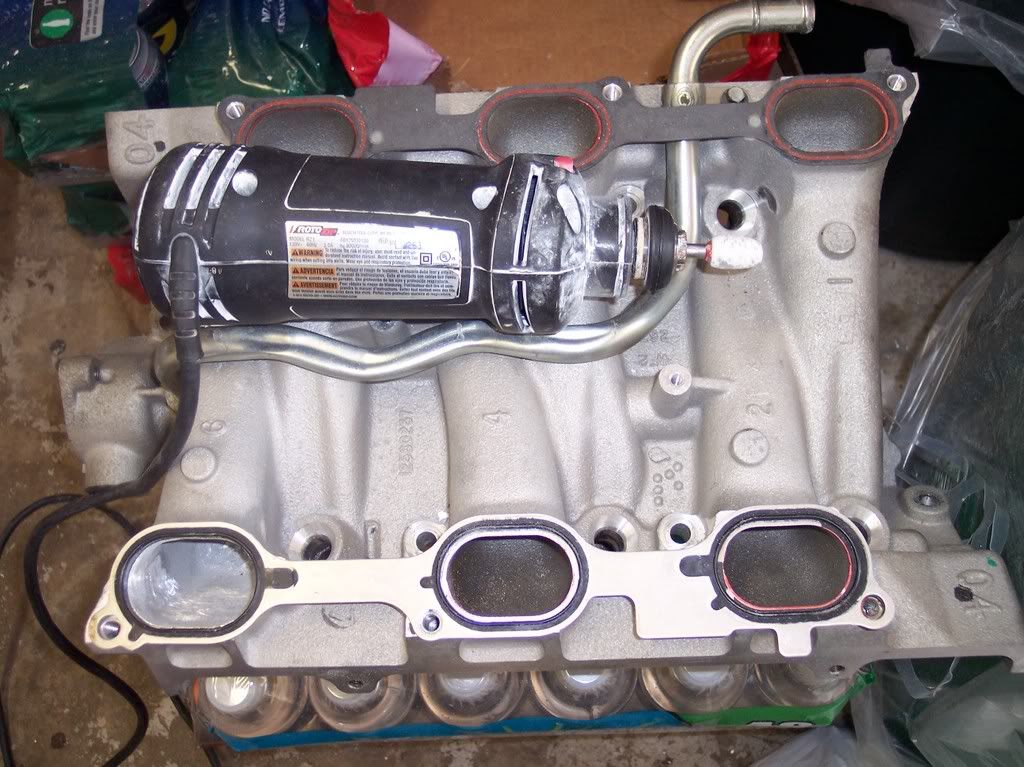

Hmmm. You work fast. Must be the rotozip. Between my die grinder and dremel it took me forever. Of course I also ground the plenum neck, took of the square, and side and front tabs, took off the casting seams too.

Announcement

Collapse

No announcement yet.

Porting suggestions/pics for 3x00 heads

Collapse

X

-

Looks like one of his stones did start to load up, mostly the round white one.... A trick to use stones on aluminum/soft metal is to soak the stones in kerosene and keep plenty on the stone while grinding. Another trick for grinding soft metals is to load the grinding wheel with bees wax. THAT is messy tho. Stick with kero. It will also give a MUCH better finish!!

Tom

Comment

-

Note in pic 4 of post #30, there is a wire brush. Halfway between each port, I would hit the wire brush on the stone while the Zip was running . I buy the stones for $7 for an assorted pack at Harbor Freight, and at 14k RPM, they work great as long as you don't press too hard. They cut really fast if you just barely touch the aluminum. I'm still going to sand to make them nice and shiney

. I buy the stones for $7 for an assorted pack at Harbor Freight, and at 14k RPM, they work great as long as you don't press too hard. They cut really fast if you just barely touch the aluminum. I'm still going to sand to make them nice and shiney

EDIT: The sphere just didn't get hit with the brush after I was finished, the pink stone did.Last edited by ForcedFirebird; 09-23-2007, 12:59 AM.

Comment

-

$$, the stones work fast enough for me. I don't do this everyday.Originally posted by SappySE107 View PostCarbide burrs work faster and last longer and don't clog up nearly as bad. Makes life easier with aluminum.

BTW: RotoZip spins @ 30,000 RPM (with the force of a hand drill), 14k is the angle grinder. MY collet on the Zip can go from 1/4" down to 1/16".

Comment

-

I bought a pneumatic die grinder for porting my 3500 upper. After the third port, I switched back to my dremel. Our air compressor doesn't have a really large holding tank and the compressor was running almost non stop. The dremel was much better for me because there wasn't a bulky trigger that I had to hold down. With the dremel, I just set the rpm and went to work.

Comment

-

I have 25 gallons of air, but like you say, I just turn it on and go. This thing sounds like a router, but is small enough to hol in one hand.Originally posted by whitelightnin04MC View PostI bought a pneumatic die grinder for porting my 3500 upper. After the third port, I switched back to my dremel. Our air compressor doesn't have a really large holding tank and the compressor was running almost non stop. The dremel was much better for me because there wasn't a bulky trigger that I had to hold down. With the dremel, I just set the rpm and went to work.

Comment

-

I used a dremel with a carbide burr tip, took the inital amount off beautifully, and then I went at it with a 120 grit flapper wheel and then a 80 grit

looked very similar to yours.

Got Lope?

3500 Build, Comp XFI Cam 218/230 .050 dur .570/.568 lift 113LSA

Fully Balanced, Ported, 3 Angle Valve Job, 65mm TCE TB, S&S Headers.

Stage-1 Raybestos/Alto 4t60e-HD, EP LSD, 3.69FDR

12.61@105 Epping NH Oct 2015 Nitrous 100shot (melted plugs) 13.58@98.8 N/A 3200LBS

Comment

-

It's made by central pneumatic and is smaller than your rotozip. I got it from harbor freight for like 18 bucks. It came with a bunch of stones also.Originally posted by ForcedFirebird View PostI have 25 gallons of air, but like you say, I just turn it on and go. This thing sounds like a router, but is small enough to hol in one hand.

When I ported mine, I found that the carbide cutter worked great in the dremel because I had a much steadier hand. I came back behind it with a stone and sanding drums.

Comment

-

This was done in one step with the stone. Just had to get more and they are on sale for $3.99 for five assortedOriginally posted by 3400-95-Modified View PostI used a dremel with a carbide burr tip, took the inital amount off beautifully, and then I went at it with a 120 grit flapper wheel and then a 80 grit

looked very similar to yours.

Comment

-

I have a Dremmel also (just Craftsman's version). All the tools/accessories from Dremmel fit it.Originally posted by whitelightnin04MC View PostIt's made by central pneumatic and is smaller than your rotozip. I got it from harbor freight for like 18 bucks. It came with a bunch of stones also.

When I ported mine, I found that the carbide cutter worked great in the dremel because I had a much steadier hand. I came back behind it with a stone and sanding drums.

Comment

-

There was a cheap set of carbide metal rasps at harbor freight, but I was told it would clog up on aluminum and you need special ones. They looked like they had huge spaces between the cutting parts, I should of got them I doubt they would have clogged like the stone wheels.

The dremel just didn't seem to work well. If I used the die grinder bits on it the glue would let loose due to the heat. The die grinder worked good as long as it had air. I would push hard to take off a ton of metal before the tank emptied. It chews the stone down fast that way, but was quicker to get it done. The stones didn't clog since it didn't sustain power long enough to get the aluminum hot and sticky. Plus pressing hard helped clean the stones and large chucks flew off the stone a lot.

Yeah my dremel is the craftsman one. Two speed. I used the low speed.

My air die grinder I got for $7 at harbor freight with a case and stones included.

I wish I had tried those metal rasp bits. Oh well all the sweat and work is done. The stones I found the red and black ones worked well, but the white was too soft and basically disintegrated. Only good for polishing.

I do like air though because if it gets stuck it stops. Electric motors when they get stuck they slow down and the torq goes crazy and then it skips across a gasket mating surface!!! I always put like 3-4 layers of masking tape on the sealing surfaces as insurance. I had a few slips and the tape was enough to save me.sigpic New 2010 project (click image)

New 2010 project (click image)

1994 3100 BERETTA. 200,000+ miles

16.0 1/4 mile when stock. Now ???

Original L82 Longblock with LA1, LX9, LX5 parts

Manifold-back 2.5" SS Mandrel Exhaust. Hardware is SS too.

Comment

-

Those rasps suck, tried them. I should take a pic of what happened when I just touched a piece of scrap to check them out. I picked them up when I went to HF today. Just ended up going back to the sphere.

The RotoZip is nearly impossible to stop, and doesn't even slow much when pressing hard.

I touched the gasket surface once at the top of the LIM, but not too bad. I think a little RTV will make it OK, but may go ahead and take .010" off the top before assembly.

I only got one more top port on the LIM today. The wife had me working on the washer for a while, then the kids came home from Aunties house, and have been hanging with them since.

Comment

Comment