Got my gaskets finally, and will start porting this weekend. I was fitting the gaskets on and noticed two surfaces of the heads lined up with the gaskets.

I'm planning on a gasket match, but was unsure on a couple of things.

1. Are you guys removing material from the port floor/wall? It looks like a little can be removed to make a more direct shot to the valve.

2. Has anybody ported to the carbon stains around the exhaust ports? I've seen pics of some of your portings, and nobody has gone that far.

3. How large should I go? I'm planning on using Camaro 3.4 pistons and 3500 heads to get up and running again, but then switching to 3400 pistons to re-boost the car, which leads to my next questions:

1. When modifying the chambers, I see the valves could be slightly less shrouded as there is a little material, almost like a lip, up against the valve. OK to remove?

2. The large area around the sparkplug, should I just smooth the edges here?

3. The sharp edges on the heart-shape, OK to remove?

And one more not totally pertaining to my 3500 heads. What do you think the effects would be if I wrote a CNC program to remove material from 3400 heads, in the same shape/size as the head gasket to lower compression for some RWD friends of mine that are scared to do the swap because of having to change pistons?

Pics/suggestions would be greatly appreciated!

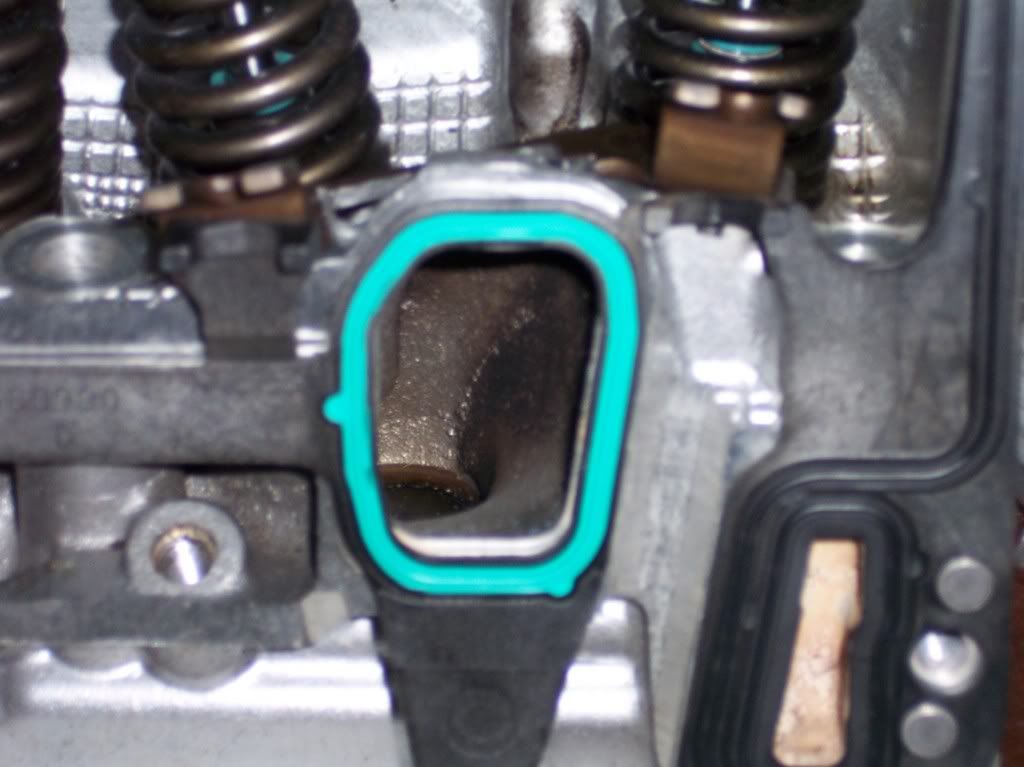

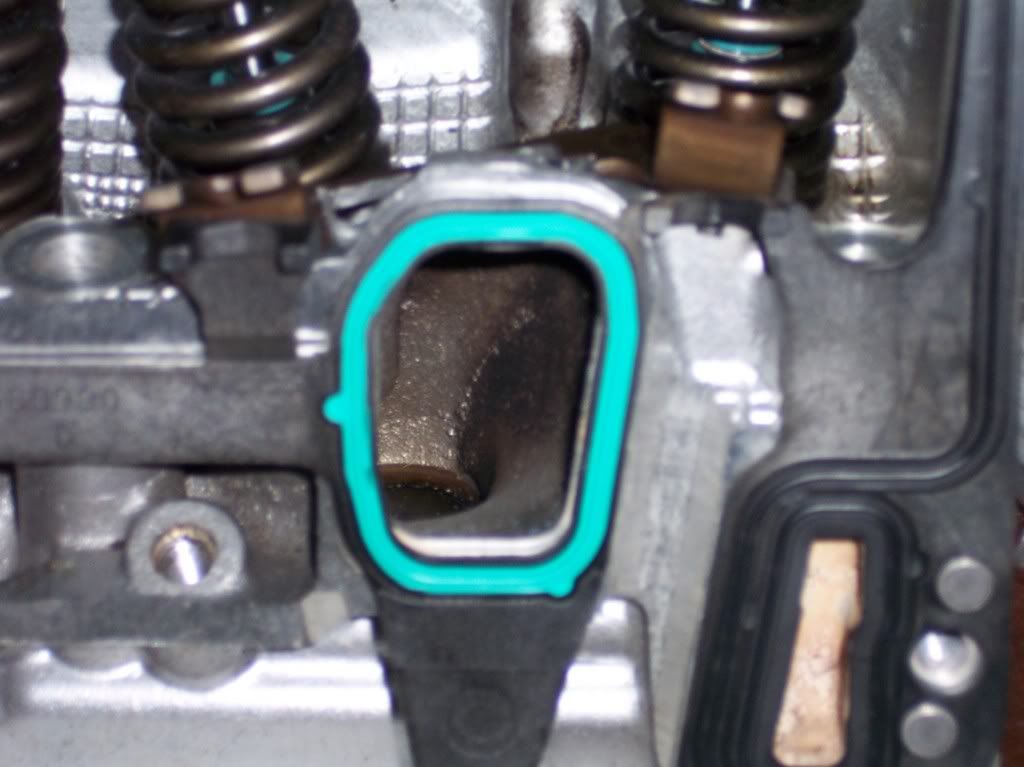

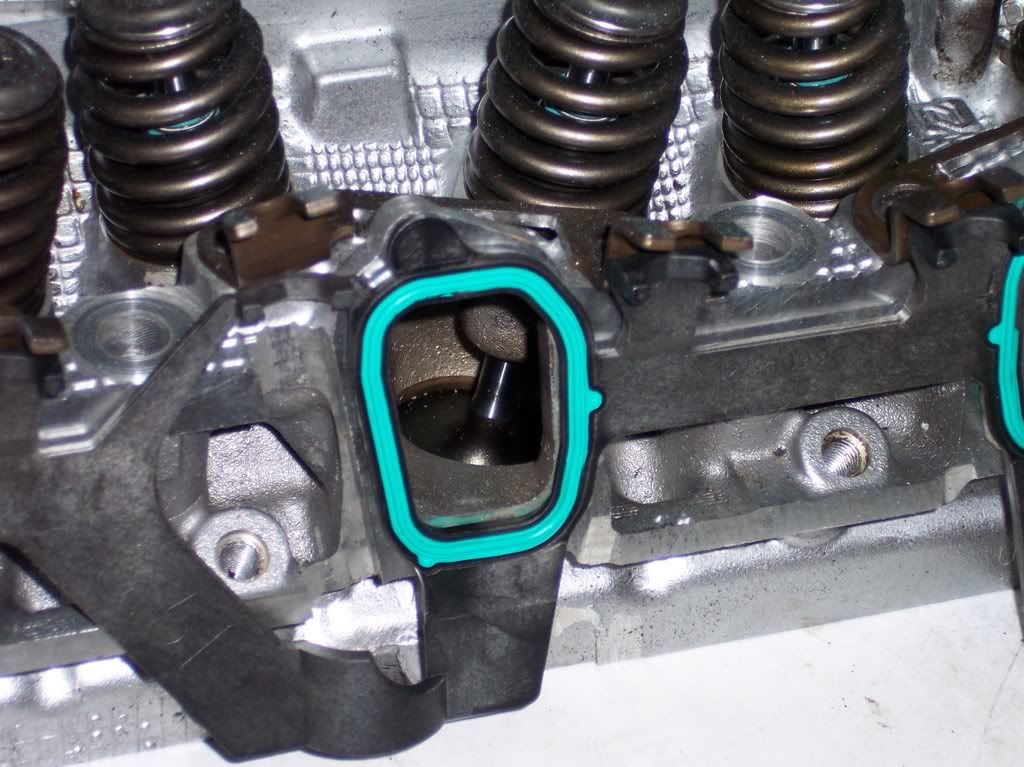

Here's the wall I'm talking about...

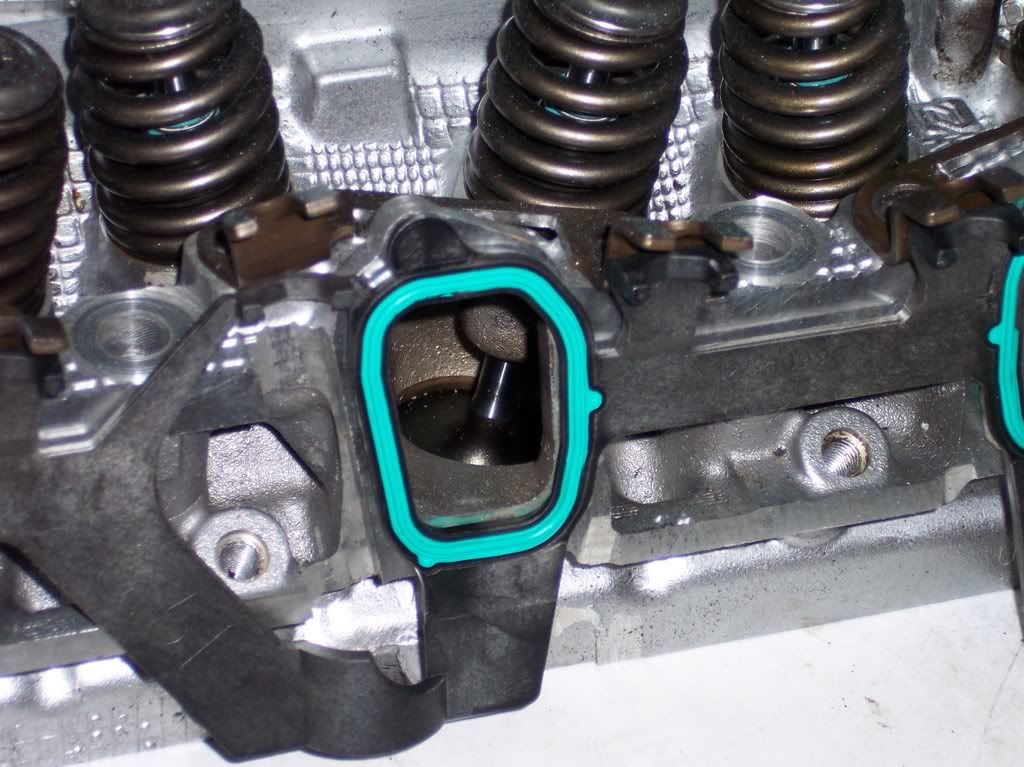

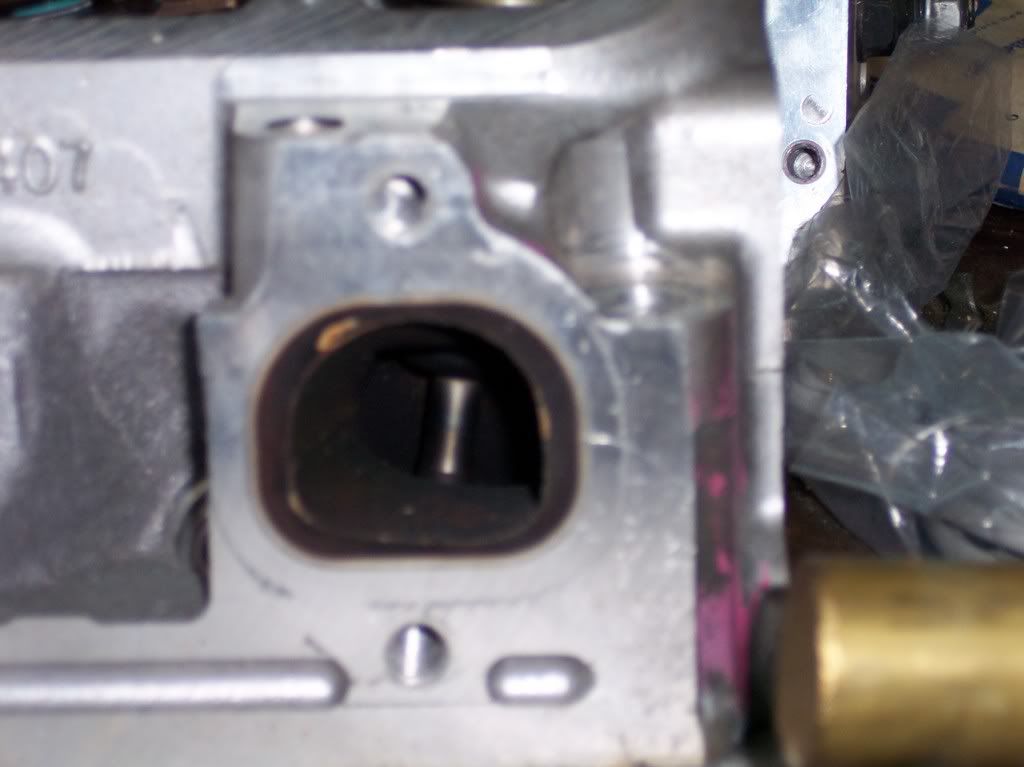

Here's the floor I'm talking about...

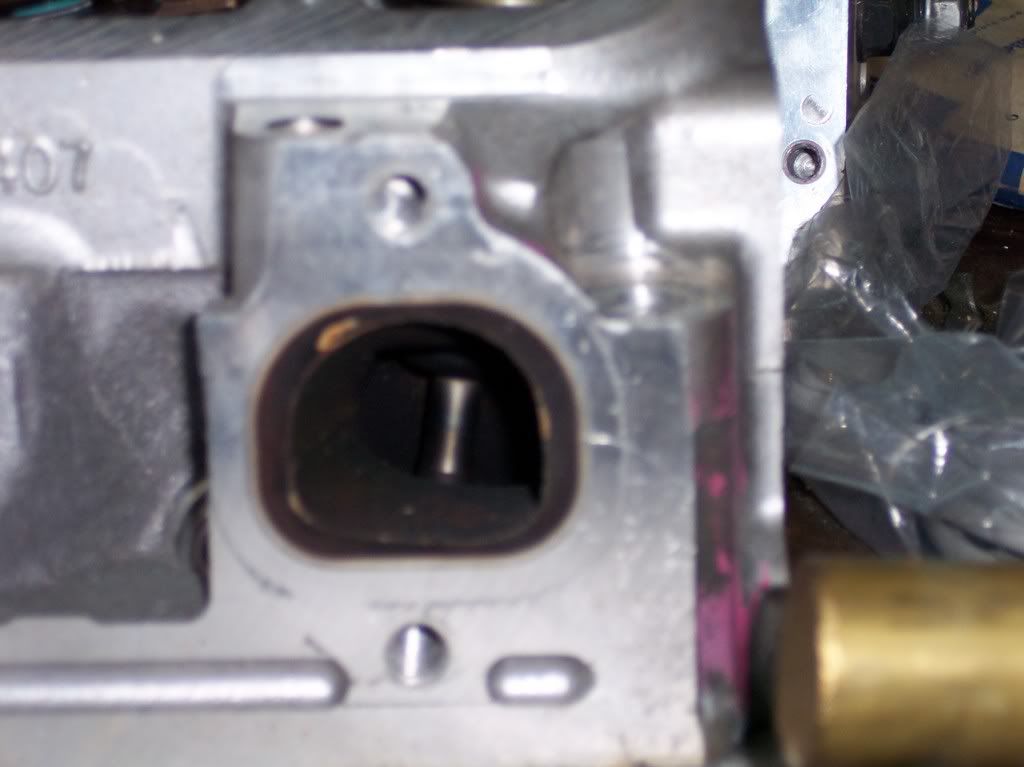

Here's the carbon ring I am talking about around the exhaust ports, since I am making my own headers/flanges, but just don't know if that's overporting?...

I'm planning on a gasket match, but was unsure on a couple of things.

1. Are you guys removing material from the port floor/wall? It looks like a little can be removed to make a more direct shot to the valve.

2. Has anybody ported to the carbon stains around the exhaust ports? I've seen pics of some of your portings, and nobody has gone that far.

3. How large should I go? I'm planning on using Camaro 3.4 pistons and 3500 heads to get up and running again, but then switching to 3400 pistons to re-boost the car, which leads to my next questions:

1. When modifying the chambers, I see the valves could be slightly less shrouded as there is a little material, almost like a lip, up against the valve. OK to remove?

2. The large area around the sparkplug, should I just smooth the edges here?

3. The sharp edges on the heart-shape, OK to remove?

And one more not totally pertaining to my 3500 heads. What do you think the effects would be if I wrote a CNC program to remove material from 3400 heads, in the same shape/size as the head gasket to lower compression for some RWD friends of mine that are scared to do the swap because of having to change pistons?

Pics/suggestions would be greatly appreciated!

Here's the wall I'm talking about...

Here's the floor I'm talking about...

Here's the carbon ring I am talking about around the exhaust ports, since I am making my own headers/flanges, but just don't know if that's overporting?...

Comment