Announcement

Collapse

No announcement yet.

300 hp N/A carb 2.8 V6 engine

Collapse

X

-

He has a fully custom made forged crankshaft IIRC, so in all honesty he could have had that made to be any stroke he wanted and then work with the larger block but he opted to stay with the 3100... Might be due to lack of 3500 engines in Finland.

-

There used to be a 2500 V6 in the Buick of China market with a 66mm or so stroke... If he could snag one of those cranks, he could use the 3400 or LX9 block while staying within his displacement limits

Leave a comment:

-

Guest repliedYep, that would make sense... I forgot about that when 34blazer and I were talking about that...

Guest repliedYep, that would make sense... I forgot about that when 34blazer and I were talking about that...

Leave a comment:

-

He is using the 3100 block and from what I've read the chambers over hang the cylinders.Originally posted by 34blazer View PostVeekusi, why don't you go with LX9 heads?

Sent from my XT1080 using Tapatalk

Leave a comment:

-

I sent you an email April 5th.Originally posted by veekuusi View PostI quess , it is a 3100 cylinder head.

I just realized that you may need different lower intake gaskets than what you have been using. We went with a pair of 94-95 3100 heads without the roller rockers stock, so the rocker arm bolt holes start at the top, without a notch cut for the 96+ pedestal mount rockers. The alignment pin for the middle intake port changed from an offset to the middle. Please let me know if you need the lower intake gaskets to match this. If you have a part number for the gasket you are using, I can verify that way as well.

Ben Phelps

WOT-Tech

Leave a comment:

-

I didn't think to check that when I got the heads back from the machine shop for the valve job. That is the issue, and my mistake. While the OD is fully acceptable for the 1.76" seat, the ID needed to be opened up. We will be flowtesting every set from now on. If you want to send the heads back, I will fix them. If not, its an easy enough task. I really don't know about the exhaust though. Same seats across the board with those and the pic looks right to me for the angles. I thought our intake cutter was a steeper angle to open them up more but apparently not. I have no excuses for it.

Also, it doesn't appear the measurements are at the same point in the seat. I won't be able to measure stock vs stock 3.1 to 3.4 until I get back to Florida.Last edited by SappySE107; 05-01-2016, 03:17 AM.

Leave a comment:

-

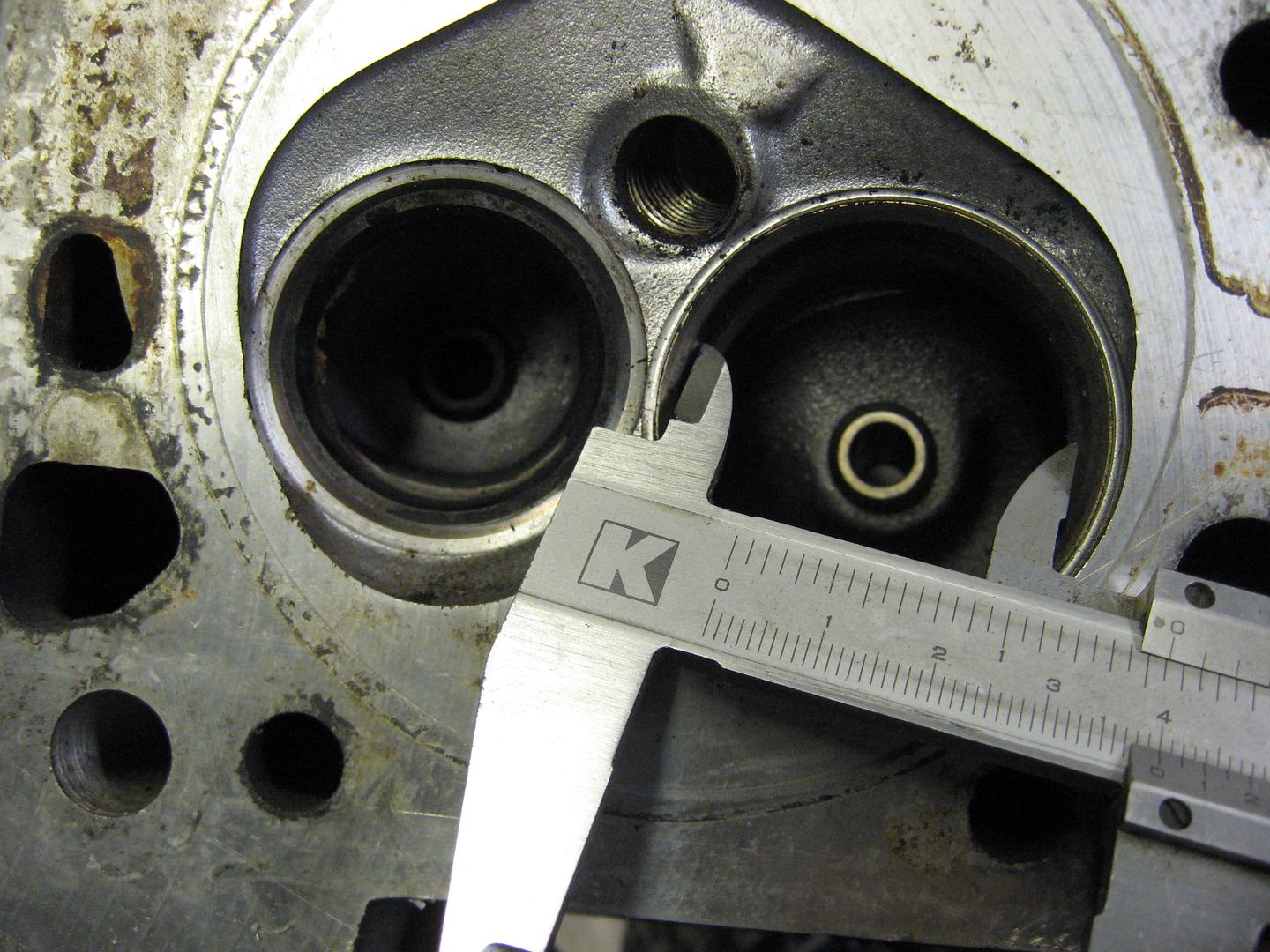

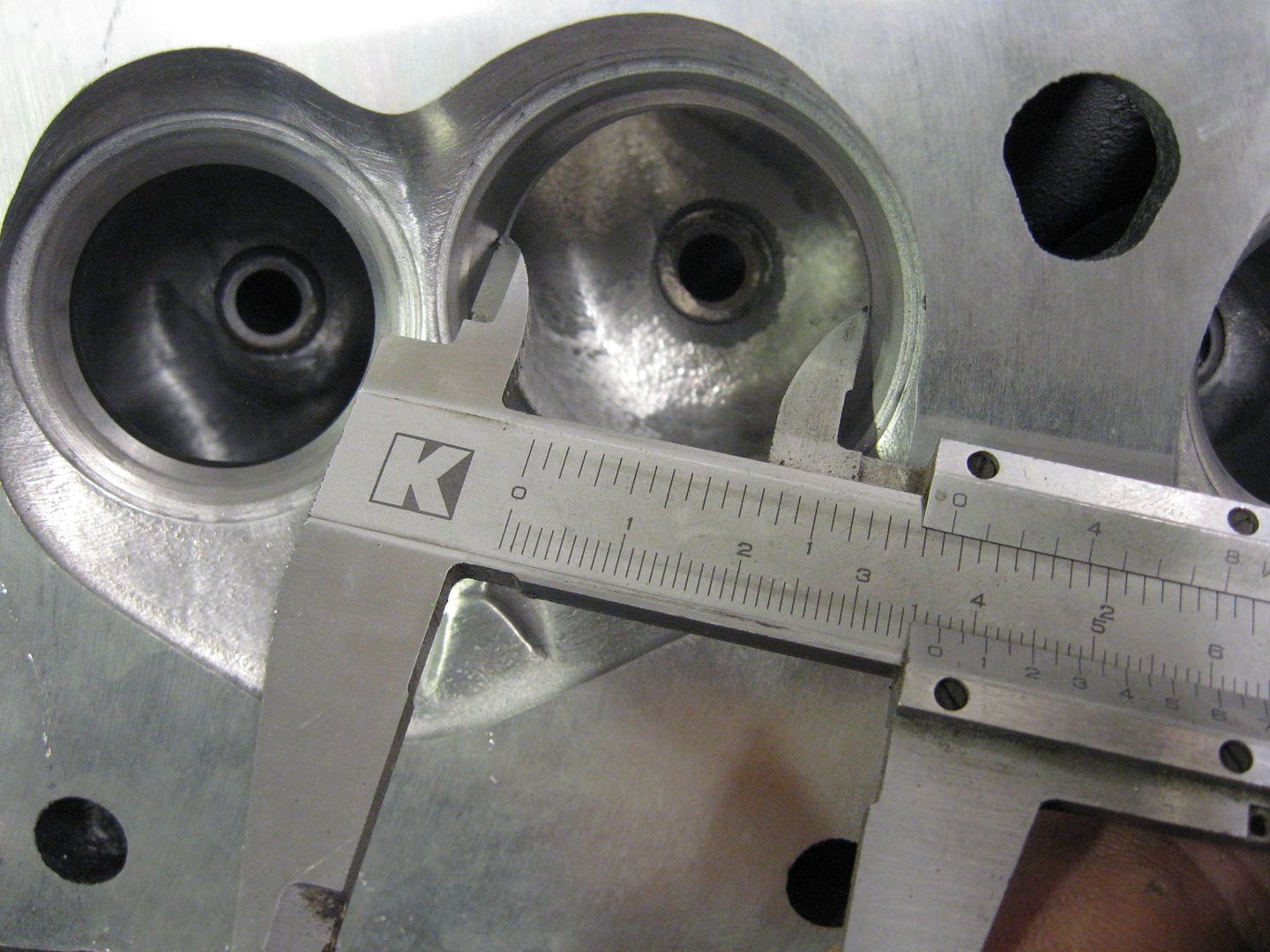

This is a photo of stock Chevrolet Trans Sport 3400 cylinder head (year model 1995) , that I have been using before..

Valve seat is 40 mm.

And thats what I expected to get from Wot Tech.

And this is a photo of a cylinder head that I got from Wot Tech.

Valve seat is 37 mm.

I quess , it is a 3100 cylinder head.

Leave a comment:

-

Veekusi, why don't you go with LX9 heads?

Sent from my XT1080 using Tapatalk

Leave a comment:

-

Guest repliedThe non roller 3100 heads did have the D shaped exhaust port.

Guest repliedThe non roller 3100 heads did have the D shaped exhaust port.

Leave a comment:

-

Didn't the non-roller heads have the round exhaust ports? Or was there a transition between those on the later D shaped exhaust port heads?

Sent from my XT1080 using Tapatalk

Leave a comment:

-

Guest repliedYes, '92, or have you forgot about some very early W or was it N bodies getting the small port 3100 head, either way the small port 3100 head was available as early as 1992 in limited chassis'. In 1994 the small port 3100 was put in every chassis (that used the 60 degree V6), other than the J-body, since it was the last year of the V6 for the J-body and the 2nd gen chassis.Originally posted by SappySE107 View Post92? Look, this is my last post. Email me if you need more information. 94-95 are non roller. He doesn't need the roller, so what is important? 94-99 3100 have a 1.72" intake. Otherwise no difference to the 3400 heads. Machine the seats to 1.76 and use 1.76 valve, and now its the same thing as a 3400 heads. Port it, even better. My point on the heads I started with was the effort to get them to where they would be as 3400 heads to start with, and that my job would have been easier in doing so. If I am going to be told that 3100 heads aren't going to be acceptable in place of a 3400 with work, im simply not going to listen to it. I don't have to answer to any one but my customers. If my customer want to throw me under the bus without question, so be it. Have fun posting on this forum about it.

Guest repliedYes, '92, or have you forgot about some very early W or was it N bodies getting the small port 3100 head, either way the small port 3100 head was available as early as 1992 in limited chassis'. In 1994 the small port 3100 was put in every chassis (that used the 60 degree V6), other than the J-body, since it was the last year of the V6 for the J-body and the 2nd gen chassis.Originally posted by SappySE107 View Post92? Look, this is my last post. Email me if you need more information. 94-95 are non roller. He doesn't need the roller, so what is important? 94-99 3100 have a 1.72" intake. Otherwise no difference to the 3400 heads. Machine the seats to 1.76 and use 1.76 valve, and now its the same thing as a 3400 heads. Port it, even better. My point on the heads I started with was the effort to get them to where they would be as 3400 heads to start with, and that my job would have been easier in doing so. If I am going to be told that 3100 heads aren't going to be acceptable in place of a 3400 with work, im simply not going to listen to it. I don't have to answer to any one but my customers. If my customer want to throw me under the bus without question, so be it. Have fun posting on this forum about it.

Leave a comment:

-

Guest repliedUmmm, machining the pedestals down will bring them down to EXACTLY what you started with on the 3100 heads. It's practical and is done often on all different heads for all different engines, especially when different rocker studs are being used than OEM. This is VERY common on early SBC, since they originally used press in studs, but when one swaps to thread in studs the top of the pedestal needs to be flat and at the correct height. I've seen this same idea used on other engines as well. Granted the machining needs to be done by a competent machine shop, due to the angles involved, but it's not unheard of. The depth into the head can be the same as what you ended up with as well, and if need be there's enough material to drill the hole a little deeper if need be.Originally posted by SappySE107 View PostMachine the pedestals down? Interesting idea for sure, but not practical. It is the length of the threads on the stud to be concerned with, and how far it goes into those threads in the head. The cost to design valves far outweighs what this market supports. They are for strength alone, considering the limits to stock haven't been found it may not be necessary.Last edited by Guest; 04-30-2016, 01:53 PM.

Guest repliedUmmm, machining the pedestals down will bring them down to EXACTLY what you started with on the 3100 heads. It's practical and is done often on all different heads for all different engines, especially when different rocker studs are being used than OEM. This is VERY common on early SBC, since they originally used press in studs, but when one swaps to thread in studs the top of the pedestal needs to be flat and at the correct height. I've seen this same idea used on other engines as well. Granted the machining needs to be done by a competent machine shop, due to the angles involved, but it's not unheard of. The depth into the head can be the same as what you ended up with as well, and if need be there's enough material to drill the hole a little deeper if need be.Originally posted by SappySE107 View PostMachine the pedestals down? Interesting idea for sure, but not practical. It is the length of the threads on the stud to be concerned with, and how far it goes into those threads in the head. The cost to design valves far outweighs what this market supports. They are for strength alone, considering the limits to stock haven't been found it may not be necessary.Last edited by Guest; 04-30-2016, 01:53 PM.

Leave a comment:

-

92? Look, this is my last post. Email me if you need more information. 94-95 are non roller. He doesn't need the roller, so what is important? 94-99 3100 have a 1.72" intake. Otherwise no difference to the 3400 heads. Machine the seats to 1.76 and use 1.76 valve, and now its the same thing as a 3400 heads. Port it, even better. My point on the heads I started with was the effort to get them to where they would be as 3400 heads to start with, and that my job would have been easier in doing so. If I am going to be told that 3100 heads aren't going to be acceptable in place of a 3400 with work, im simply not going to listen to it. I don't have to answer to any one but my customers. If my customer want to throw me under the bus without question, so be it. Have fun posting on this forum about it.

Leave a comment:

-

Machine the pedestals down? Interesting idea for sure, but not practical. It is the length of the threads on the stud to be concerned with, and how far it goes into those threads in the head. The cost to design valves far outweighs what this market supports. They are for strength alone, considering the limits to stock haven't been found it may not be necessary.Originally posted by The_Raven View PostSo these were early 3100 heads? I don't see why you wouldn't start with 3400 heads, or at least large port 3100 heads. Machine the pedestals down to the needed height and since timeserts were being installed, the height of the stock thread is irrelevant anyway due to the original thread being drilled out...

A high RPM engine would be supported a higher flowing head better. Low RPM driveability might suffer, but with the desired use of this engine I don't think low RPM drievability is of any concern. If the "race" valves flow so poorly, why wouldn't a different set be sources with better shape to promote better flow? I highly doubt any serious racer would trade off flow for... I'm not sure what... strength? Weight? Maybe 30 years ago, but not today with the valves that are available and for reasonable prices, considering the application.

Leave a comment:

-

Guest repliedI think you're saying that all heads are the same for the 3100 and 3400 after 2000, which is correct as far as I've seen, but it sounds like you started with early 3100 heads, since ALL gen3 heads were "roller" after 1996, even the small port heads. It was only 1992 to 1994 small port 3100 heads that were not roller rocker heads.Originally posted by SappySE107 View PostNoted. Same thing in 2000, totally different before then.Last edited by Guest; 08-22-2020, 10:34 AM.

Guest repliedI think you're saying that all heads are the same for the 3100 and 3400 after 2000, which is correct as far as I've seen, but it sounds like you started with early 3100 heads, since ALL gen3 heads were "roller" after 1996, even the small port heads. It was only 1992 to 1994 small port 3100 heads that were not roller rocker heads.Originally posted by SappySE107 View PostNoted. Same thing in 2000, totally different before then.Last edited by Guest; 08-22-2020, 10:34 AM.

Leave a comment:

Leave a comment: