Announcement

Collapse

No announcement yet.

300 hp N/A carb 2.8 V6 engine

Collapse

X

-

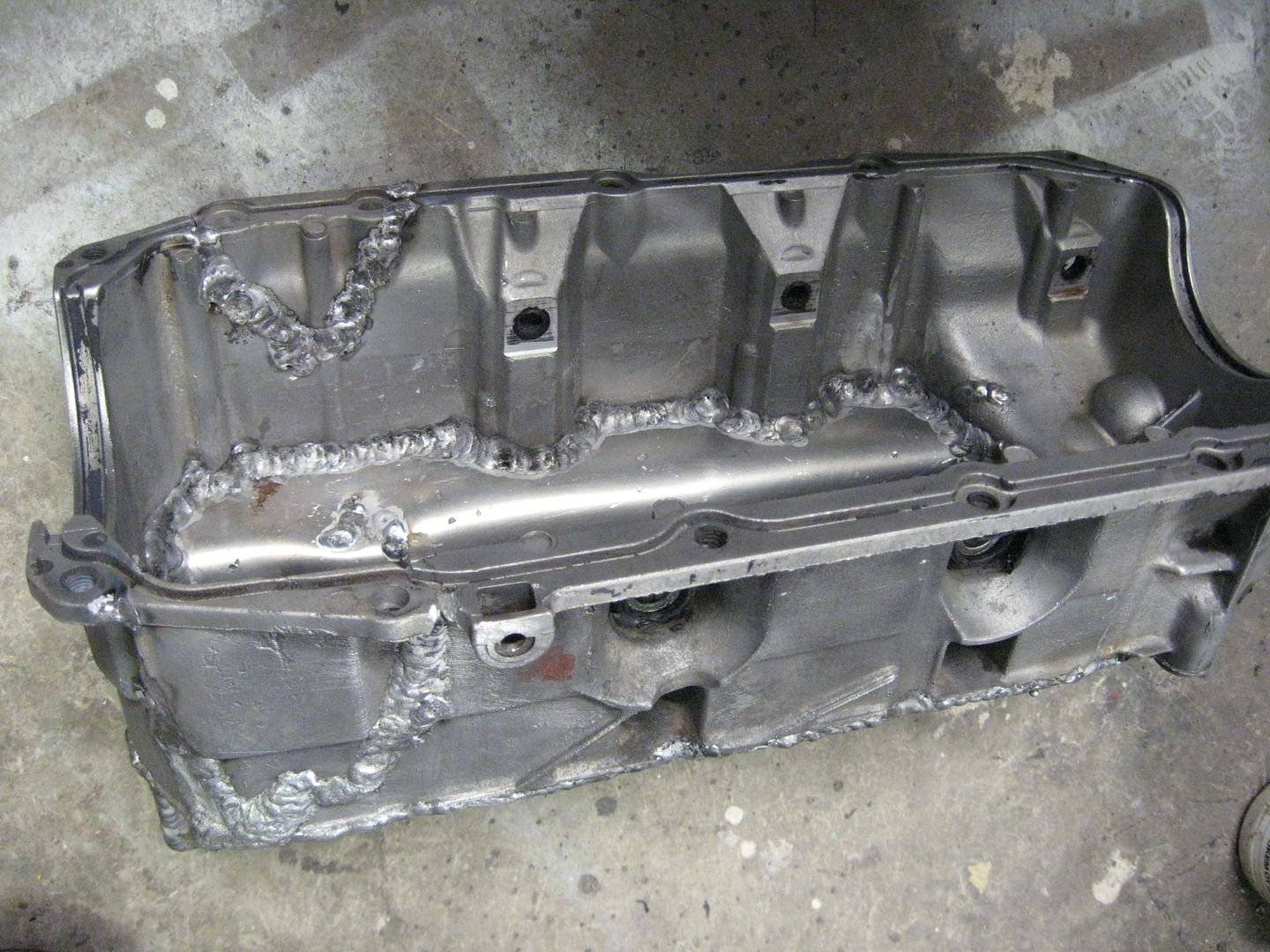

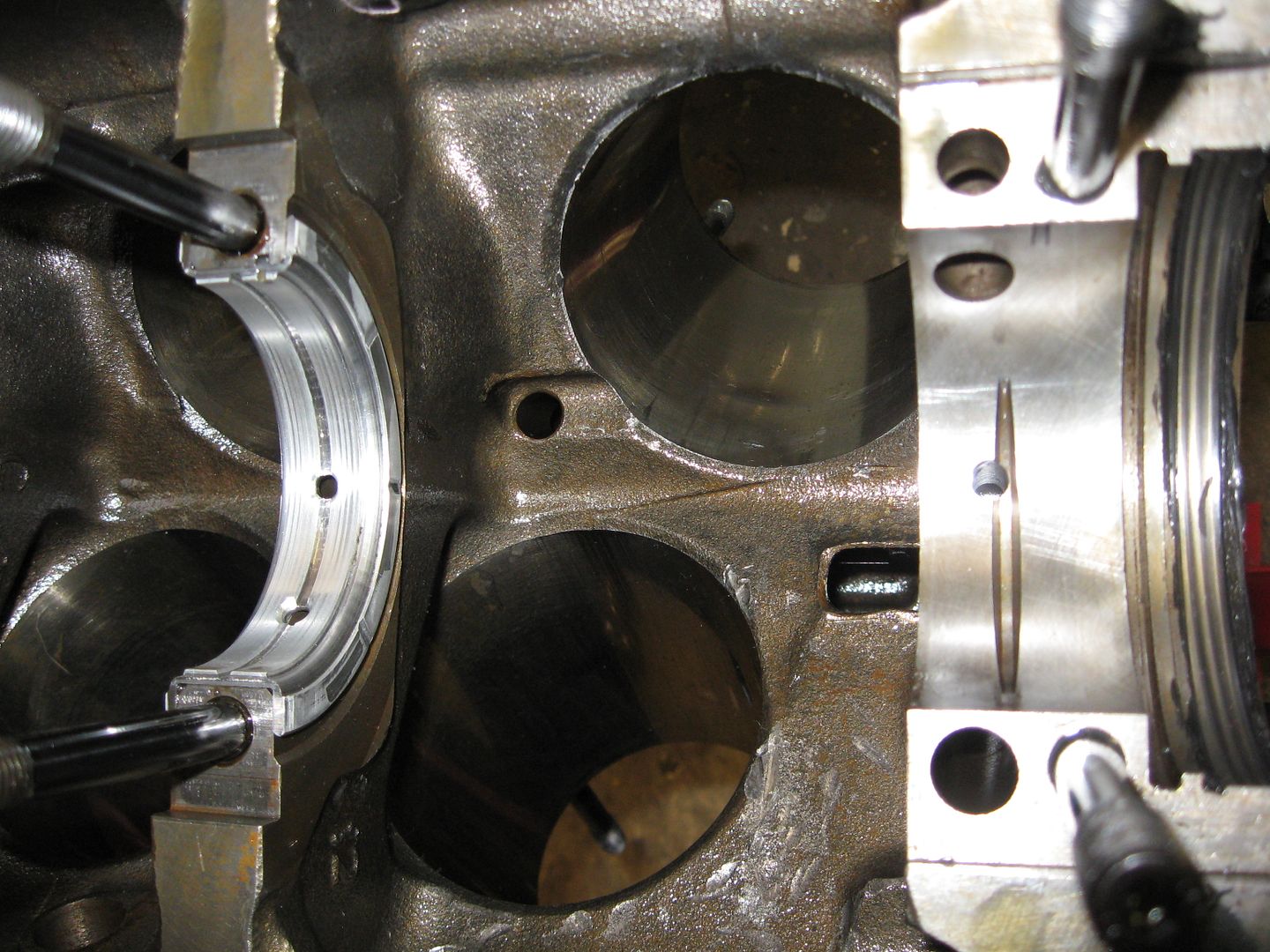

Today I was repairing the oil pan.

Some minor damage from last summer.

Leave a comment:

-

Hey guys, I appreciate your support.

1 new piston, 5 old ones.

2 new connecting rods, 4 old ones.

12 new connecting rod ARP bolts.

Leave a comment:

-

Hi everybody!

I try one more time to put the engine back together.

To race the coming season summer 2016.

One new piston, two new connecting rods, new block.

New ported heads are coming from Woth Tech.

I asked them to put the 7/16-14 rocker studs to the heads,

so that I can use the old roller rockers and springs.

I quess , they though it would be easier to make the helicoil threads,

I still have not seen the heads.

But I am ,for the time being, optimistic, that they will succeed in the process, and send the

heads to me in the near future.

Leave a comment:

-

This was the third race of this season, first race for me this season.Originally posted by 1QUICKHATCH View PostHow was the damage to the top end of the engine? Was this on your first race of the season?

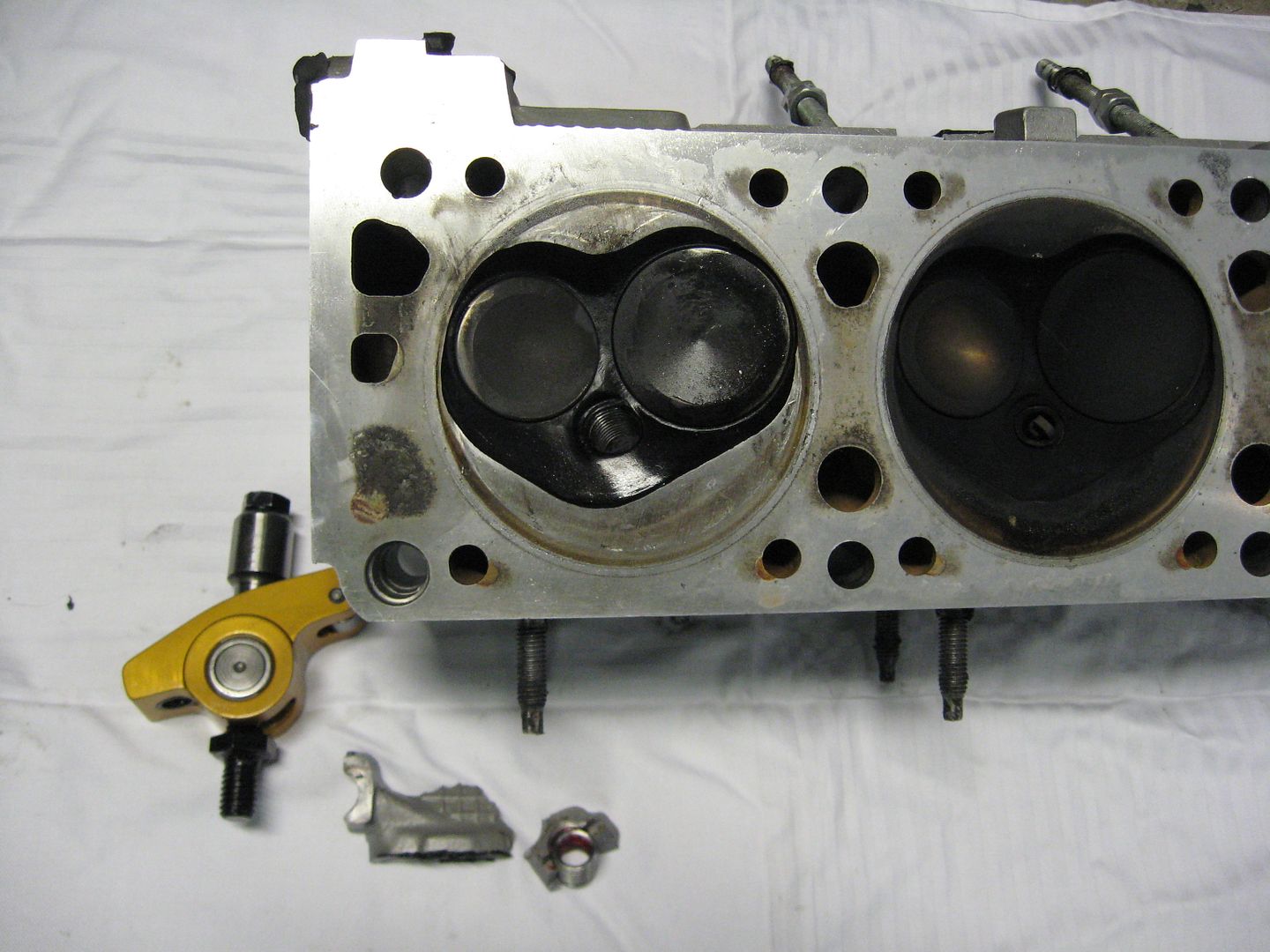

One cylinder head is damaged , the other one is fine.

#6 piston hit the exhaust valve.

Leave a comment:

-

It happens. I learned the hard way on proper bolt torque and what you are actually doing when you torque the bolt.

It looks like the damage isn't too bad, that crank can be repaired.

I would ditch those rods though, personally I don't use H-beam rods. I-beam rods are stronger and for equal strength, lighter, than H-beam designs. Lots of folks use them though so they do work, at least for a while.

Leave a comment:

-

How was the damage to the top end of the engine? Was this on your first race of the season?

Leave a comment:

-

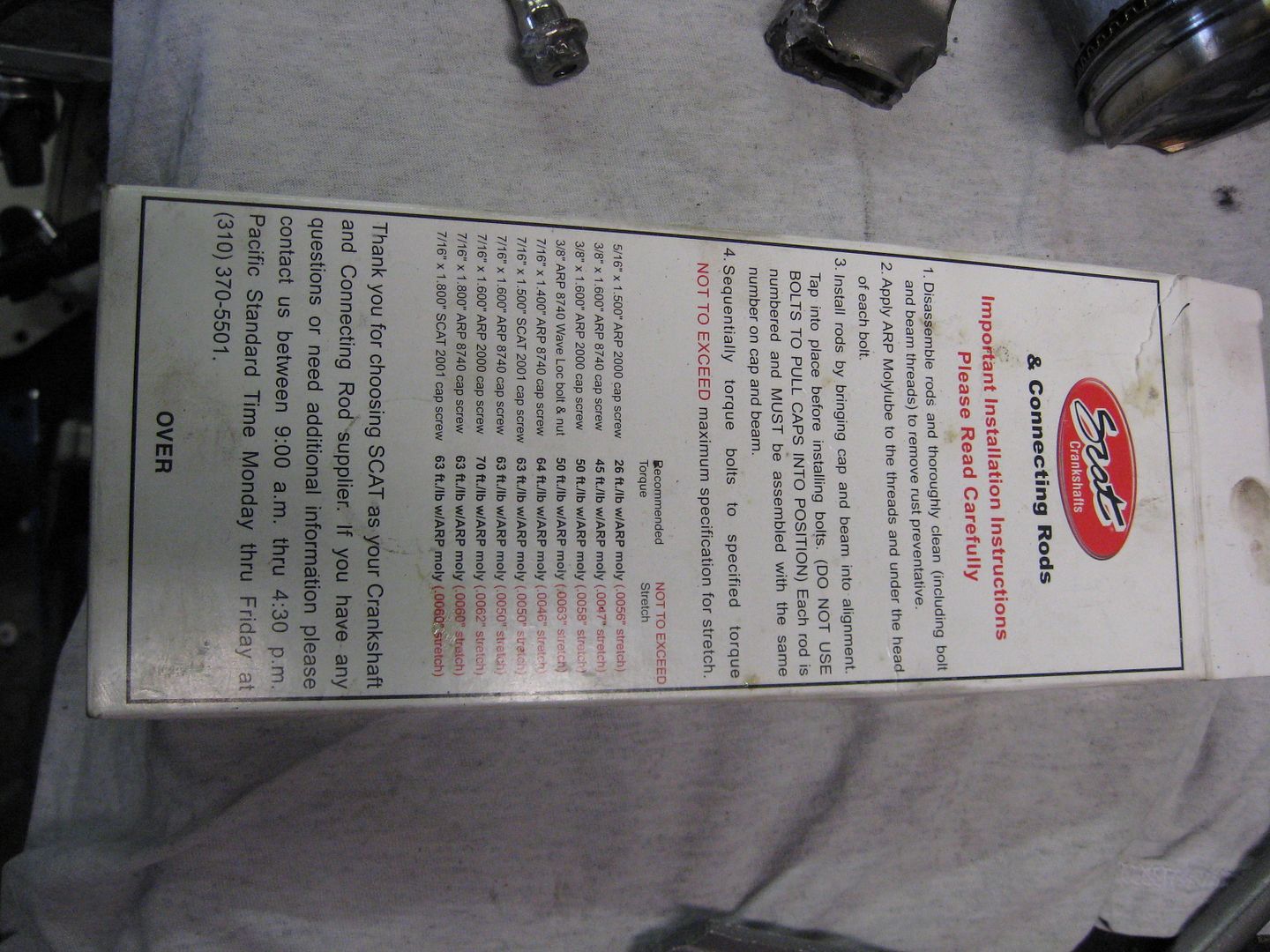

Thank you Mr Xnke for the very good explanation.

I agree with everything you said.

And it is difficult to say this loud , but maybe I had the wrong torque number in

my torque wrench all the time.

In my Scat connecting rods ,bolts are 3/8" x 1.600" ARP 8740 cap screws,

and the recommended torque for that bolt is 45 ft/lb , NOT 63 ft/lb as I have believed.

You know ,metric here and US/imperial over there .

Easy to make mistakes.

Leave a comment:

-

Those bolts should be replaced every time you tear the engine down for a rebuild. Over time as the threads in the rod and the bolt wear smooth, the actual torque you apply to stretch them to the correct length will go down. If you're just doing a re-fresh, such as bearings at the end of a trouble-free season, just measuring the bolts to make sure they're not stretched is good enough.

For example, on first installation, my new ARP rod bolts say to torque to specification three times, the third time being the final assembly. Then, Calling ARP to ask what to do for the first rebuild, they said to replace them, or at least replace the nuts with new ones. (these are rod bolts, not cap screws like you're using) Once the nuts were replaced, if the bolts are not replaced they are to be checked for necking, stretch, or other damage, and then the nuts torqued three times to spec, again, the third time being the final assembly. If the bolt has stretched beyond "X.XXX" limit, then the bolt MUST be replaced.

For cap screws, I'd have to call ARP and ask-but I would bet they're supposed to be replaced every so many torque cycles. Obviously at this point I would be buying a new set of ARP rod bolts, and recording the never-torqued length. Then, every time you tear the engine down, you can measure for bolt stretching, and any bolt stretching you find discard ALL the bolts and replace them.

What happened here, is that your bolt, having been torqued 10-15 times, had stretched, from being overtorqued. You over torqued because the thread surfaces and under-head surfaces became smooth and polished, so it took less torque to stretch the bolt the required amount for the applied pressure you need. By continuing to torque to the "new" spec, the bolt stretched beyond the elastic limit and permanently deformed-which you would catch if you measured all your bolts.

Racing engine parts have finite lifespans, even when they aren't broken out on the racetrack.Last edited by Xnke; 08-23-2015, 03:40 AM.

Leave a comment:

-

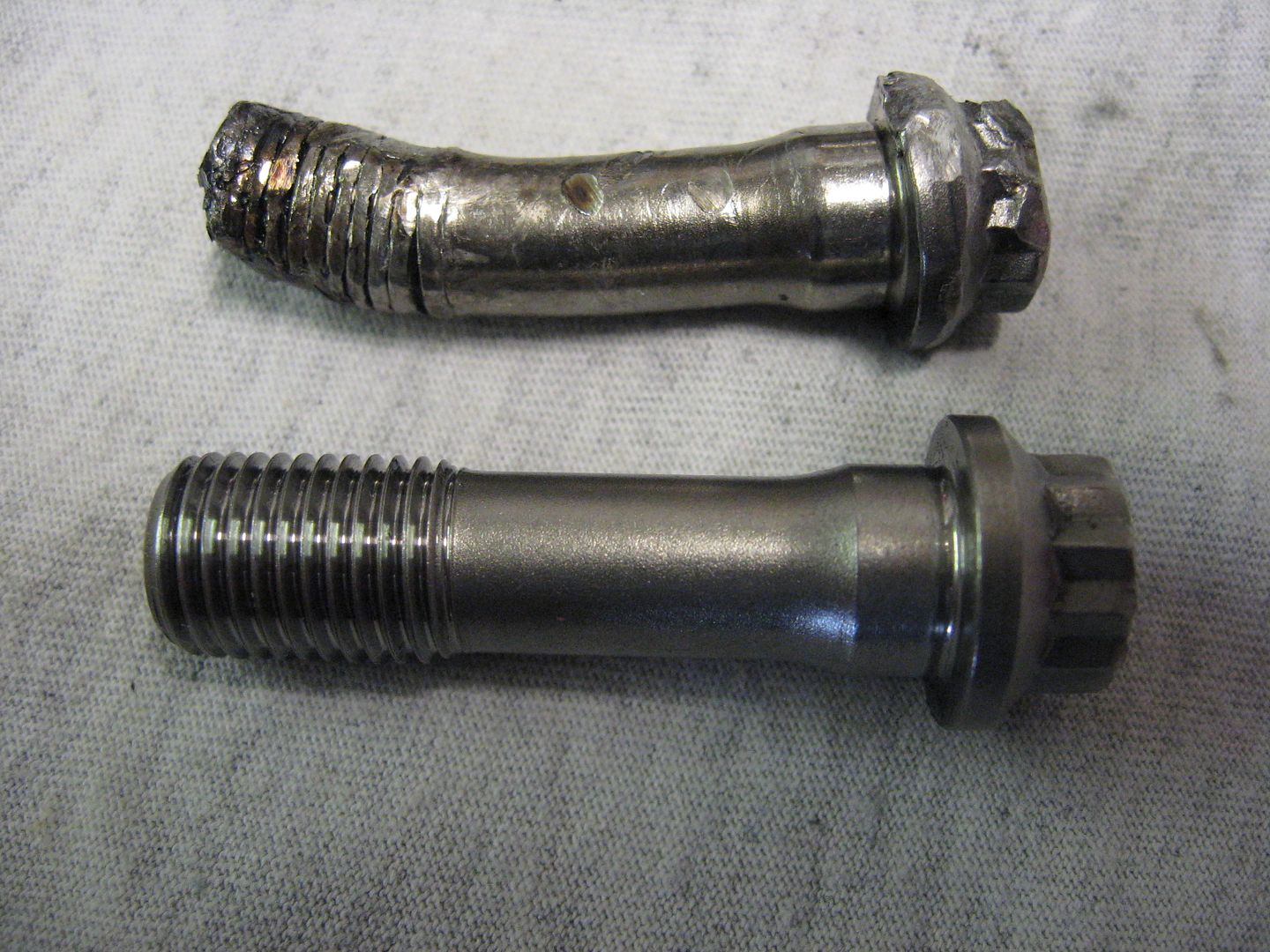

ARP molylube was used to the threads and under the head of each bolt.Originally posted by Xnke View PostHate to say it, but that's an assembly error.

Bolt on the right side broke in the threaded area, which means more than likely overtorqued on assembly. Bolt on the left side took it like a champ, but you can see where the threads pulled out from having to carry the load alone. Curious to me are the two marks on the shank of the surviving rod bolt, they look like grinding wheel marks?

When you assembled the engine, did you use the ARP assembly lubricant to install and torque those fasteners? If you didn't, or you used a different lubricant, or the fasteners have been assembled/dissassembled/ many times, then that would cause this kind of failure.

The bolts looked like new when assembled, although they were few years old.

Bolts were torqued to 63 ft/lb .

The engine has seen 2 minor damages and one major damage when the crankshaft broke one year ago.

I had to replace number 1 and 2 connecting rods and pistons last year..

Number 3,4,5 and 6 rods , bolts and pistons are old.

The damaged cylinder is number 6.

The connecting rod bolts have been tightened at least 10-15 times ,during some 4 years.

No major damage to the block, I think it can be saved.

And I think the crank shaft also can be saved.

Last edited by veekuusi; 08-22-2015, 11:36 AM.

Last edited by veekuusi; 08-22-2015, 11:36 AM.

Leave a comment:

-

Hate to say it, but that's an assembly error.

Bolt on the right side broke in the threaded area, which means more than likely overtorqued on assembly. Bolt on the left side took it like a champ, but you can see where the threads pulled out from having to carry the load alone. Curious to me are the two marks on the shank of the surviving rod bolt, they look like grinding wheel marks?

When you assembled the engine, did you use the ARP assembly lubricant to install and torque those fasteners? If you didn't, or you used a different lubricant, or the fasteners have been assembled/dissassembled/ many times, then that would cause this kind of failure.

Leave a comment:

-

Rod bolts are Scat 8740 and the rods are Scat.Originally posted by Xnke View PostNot oil starvation. You would see bluing of the rod journal or main journal, if it ran for any number of revs with low oil. That rod came apart, looks like a rod bolt failure to me. THEN you have the oiling failure caused by practically zero pressure to the rear main.

Scat rods? If so, I have seen a few instances of the Scat SBC 5.7" rod breaking around the rod journal like that with highish revs and a not-super-light piston. If you go this route again, try an Oliver rod, they're more expensive for a reason. They just don't break.

Another possible failure would be the rod bolt-if the bolts were ARP 8740 or L19, then they are VERY susceptable to corrosion cracking. Any moisture at all is a death sentence, including condensation in the engine oil, as if the engine is left sitting in unheated shop storage.

Do you have close up photos of both rod bolts and all the fractured ends of the rod and rod bolts?

One bolt came loose and the other broke.

Last edited by veekuusi; 08-21-2015, 06:45 AM.

Last edited by veekuusi; 08-21-2015, 06:45 AM.

Leave a comment:

-

Not oil starvation. You would see bluing of the rod journal or main journal, if it ran for any number of revs with low oil. That rod came apart, looks like a rod bolt failure to me. THEN you have the oiling failure caused by practically zero pressure to the rear main.

Scat rods? If so, I have seen a few instances of the Scat SBC 5.7" rod breaking around the rod journal like that with highish revs and a not-super-light piston. If you go this route again, try an Oliver rod, they're more expensive for a reason. They just don't break.

Another possible failure would be the rod bolt-if the bolts were ARP 8740 or L19, then they are VERY susceptable to corrosion cracking. Any moisture at all is a death sentence, including condensation in the engine oil, as if the engine is left sitting in unheated shop storage.

Do you have close up photos of both rod bolts and all the fractured ends of the rod and rod bolts?Last edited by Xnke; 08-21-2015, 02:02 AM.

Leave a comment:

Leave a comment: