Originally posted by 1QUICKHATCH

View Post

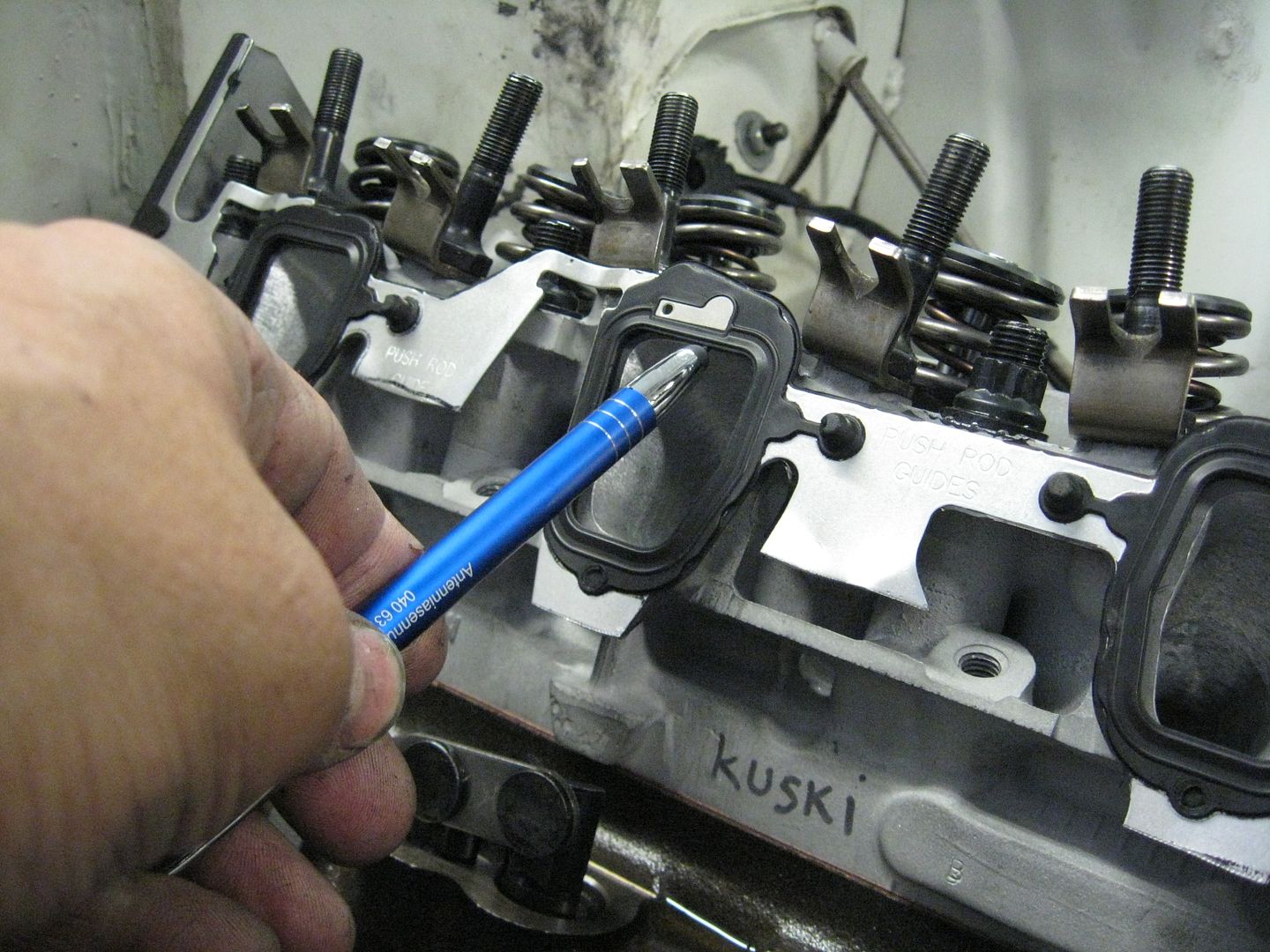

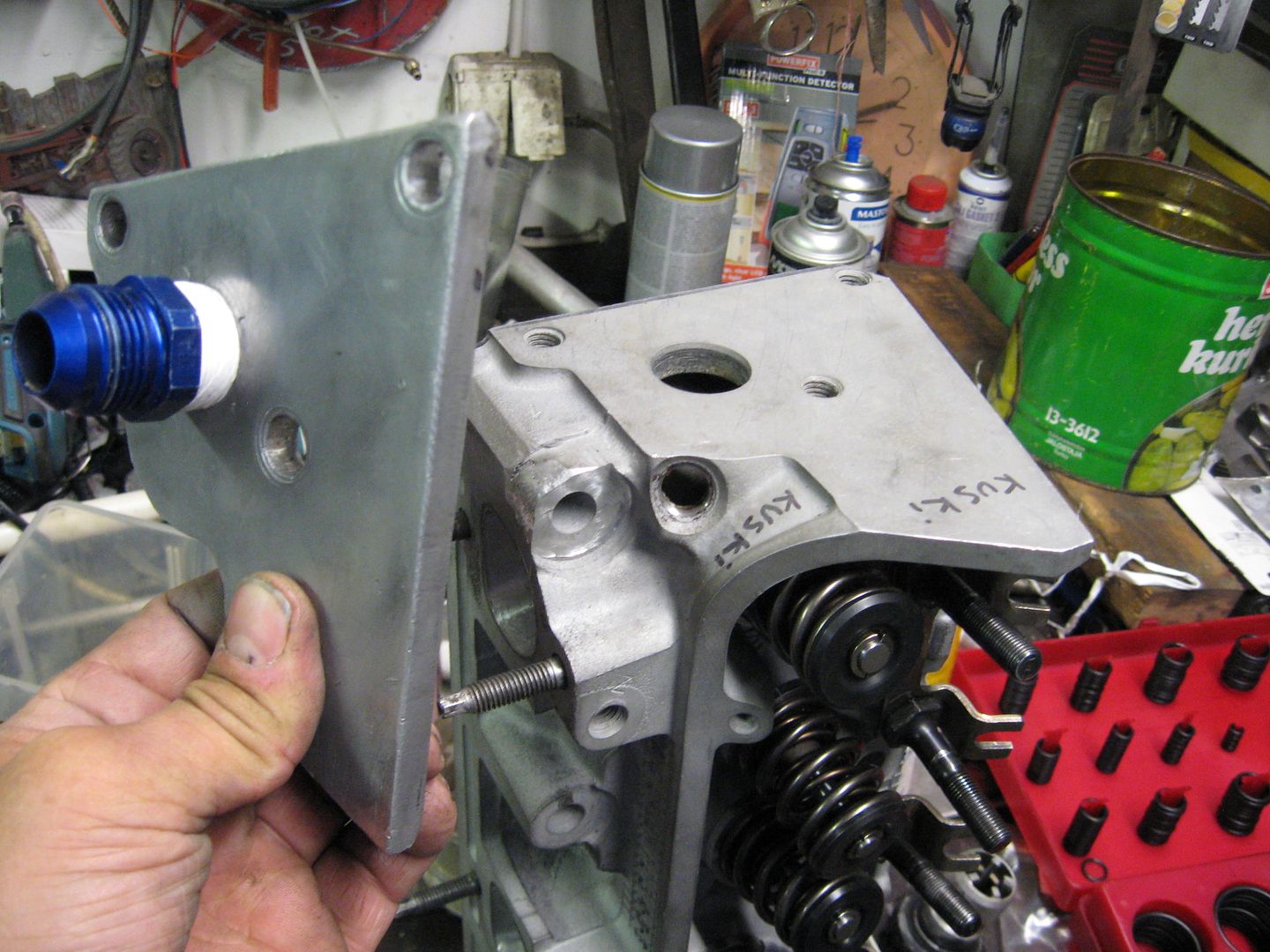

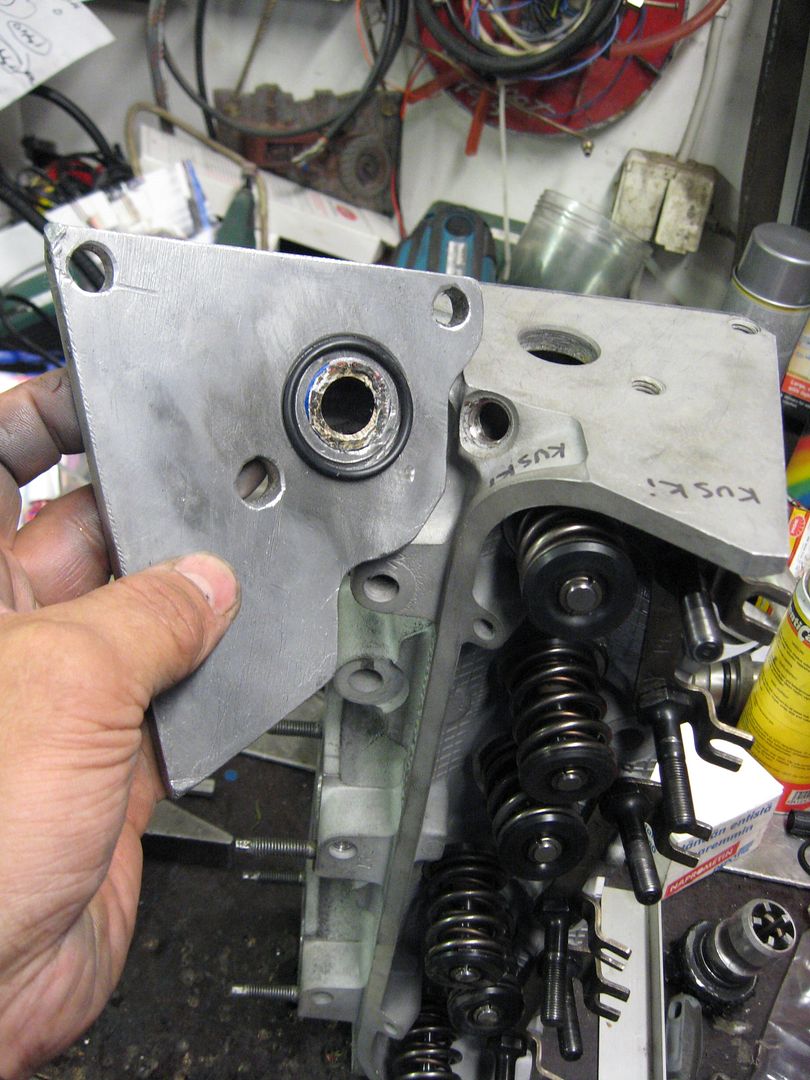

The new 3100 heads use Fel-Pro 98004 intake gaskets.

They are some 3 mm smaller on the top of the intake ports than Fel-Pro

98003 gaskets that was used earlier with the 3400 heads..

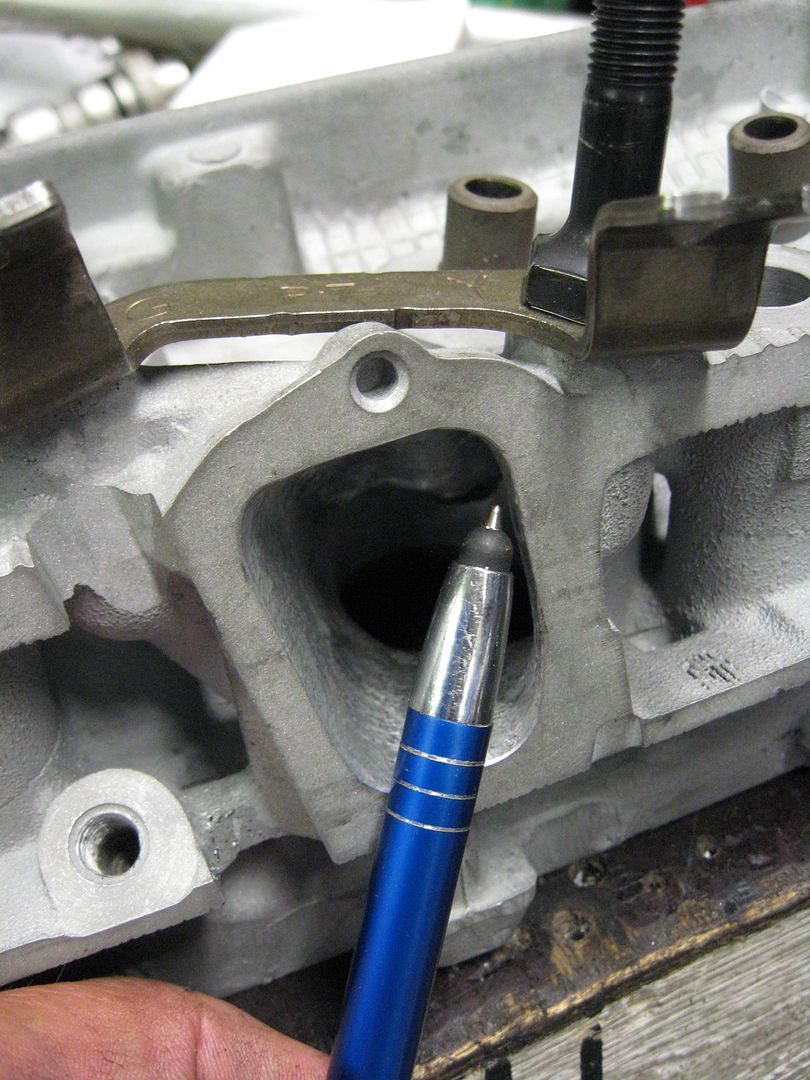

The major flow is there on the upper part of the port.

Leave a comment: