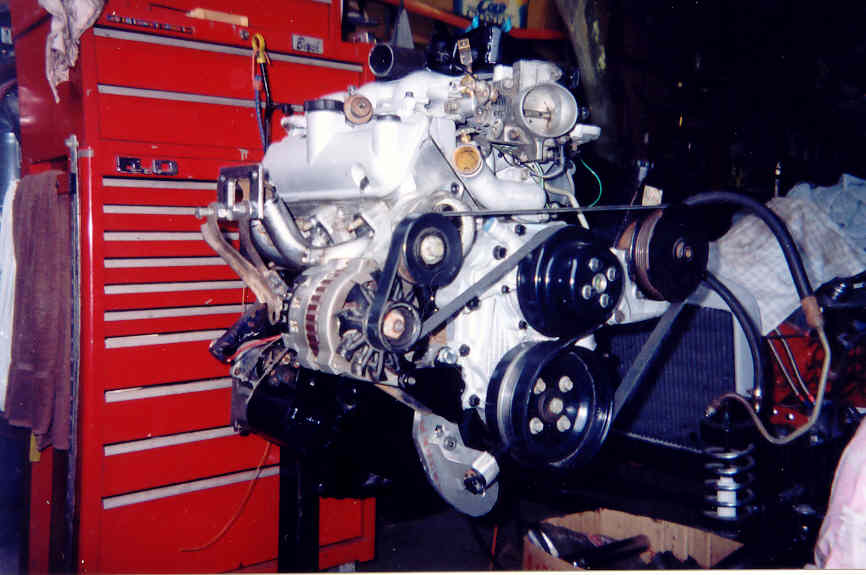

I have a bored and stroked 2.8 which i wanna go gen3 topend.

Instead of losing all the work done to my shortblock I would like to run a external crank sensor but im having a hell of a time... so much that im thinking of just swapping to the 3400 shortblock (which im also having a bitch of a time finding up here)

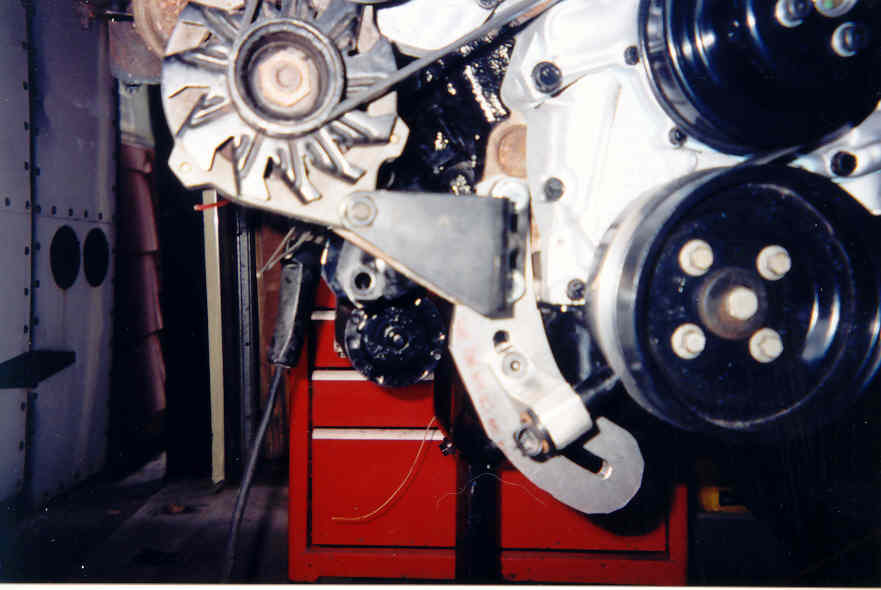

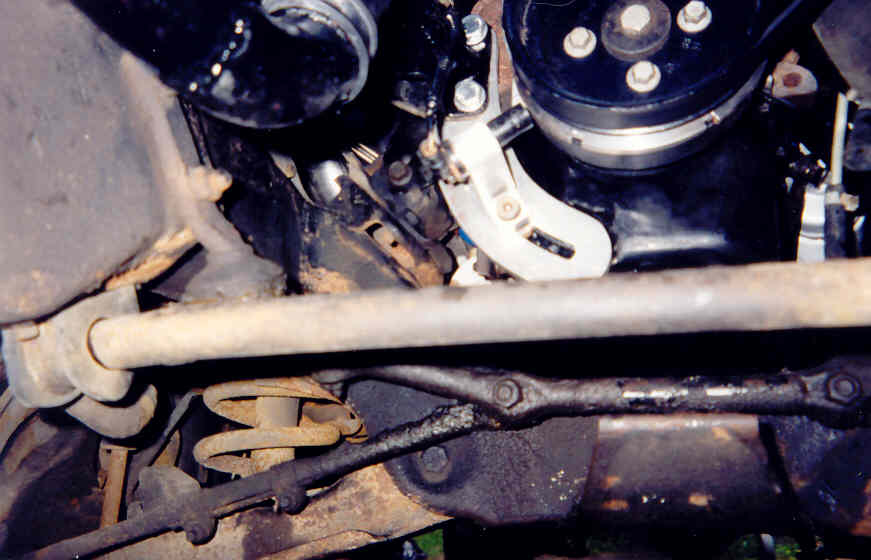

Shaun sent me a pic and an email addy of a guy who had his dad or something build one for him and it looks like what i would like to do....typical crank sensor bolted to a L bracket pointed at a disc behind the crank pulley.

Its that disc that im having issue with...mainly the diameter....once i have that then im flanged.

Anyone point me in the right direction? or have a 3400 shortblock? lol!

Instead of losing all the work done to my shortblock I would like to run a external crank sensor but im having a hell of a time... so much that im thinking of just swapping to the 3400 shortblock (which im also having a bitch of a time finding up here)

Shaun sent me a pic and an email addy of a guy who had his dad or something build one for him and it looks like what i would like to do....typical crank sensor bolted to a L bracket pointed at a disc behind the crank pulley.

Its that disc that im having issue with...mainly the diameter....once i have that then im flanged.

Anyone point me in the right direction? or have a 3400 shortblock? lol!

Comment