Wow interesting build and long thread.

There is no issue using two washers with the ARP studs, as long as the washers are ARP washers. ARP uses the same material for their washers ass their bolts they harden and flat grind them. If you use a non hardened washer you may see some deformation of the washer.

I heard about the ARP issue and decided to get custom studs made instead that fit the block. Its probably easiest to just do what you did or pay ARP for custom studs.

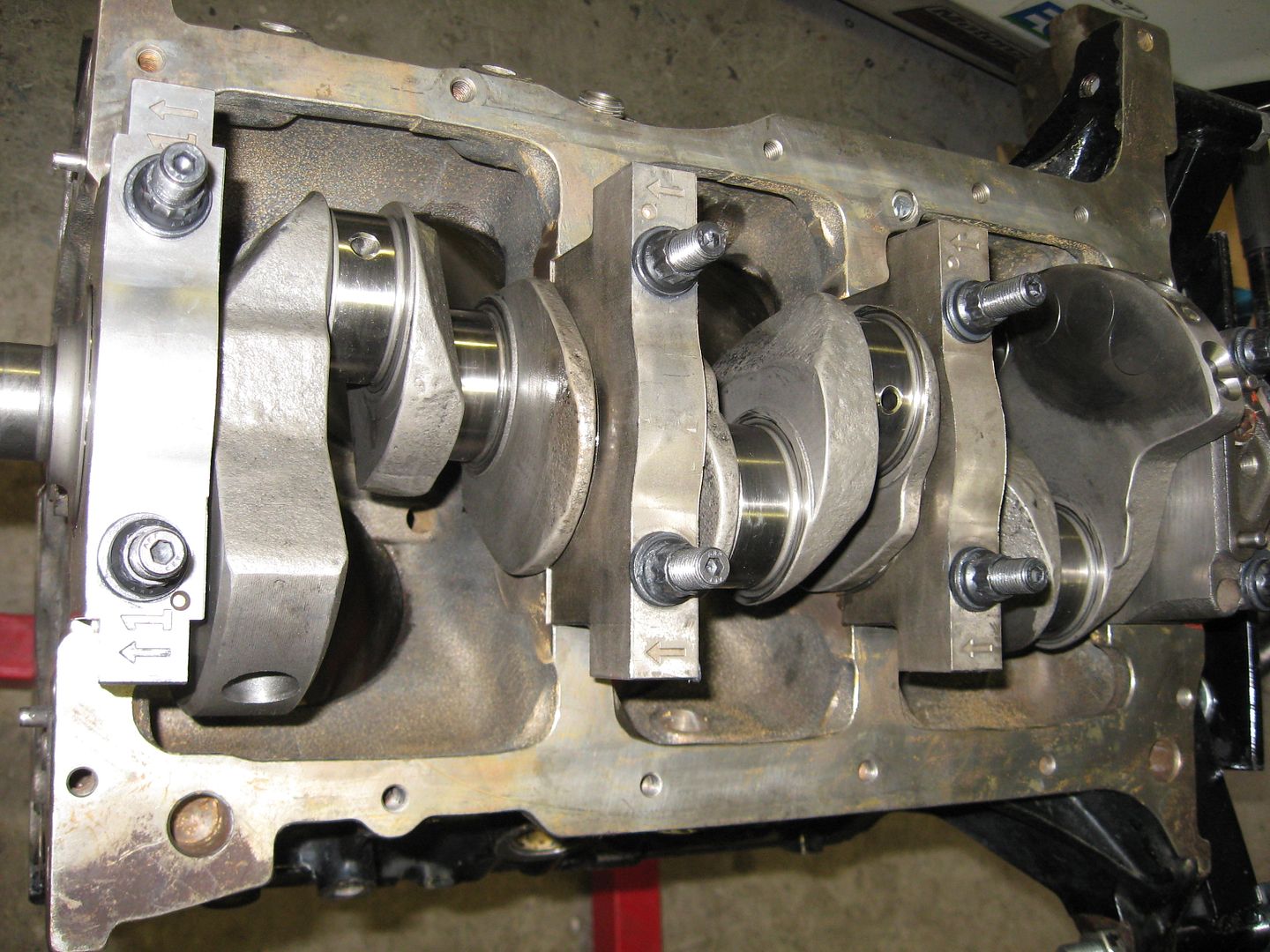

Out of curiosity the main bearing cap that was discoloured, how did it read dimensionally? Was it out of round at all when torqued in place?

Do you think you can break 300 HP without more RPM? Great build btw!

There is no issue using two washers with the ARP studs, as long as the washers are ARP washers. ARP uses the same material for their washers ass their bolts they harden and flat grind them. If you use a non hardened washer you may see some deformation of the washer.

I heard about the ARP issue and decided to get custom studs made instead that fit the block. Its probably easiest to just do what you did or pay ARP for custom studs.

Out of curiosity the main bearing cap that was discoloured, how did it read dimensionally? Was it out of round at all when torqued in place?

Do you think you can break 300 HP without more RPM? Great build btw!

Comment