1996 Grand Prix SE 3100v6 Turbo T04E .50 trim, intercooled.

6-8 psig boost, 36 lb/hr inj, custom cross-over, cat delete, valve train cleaned well.

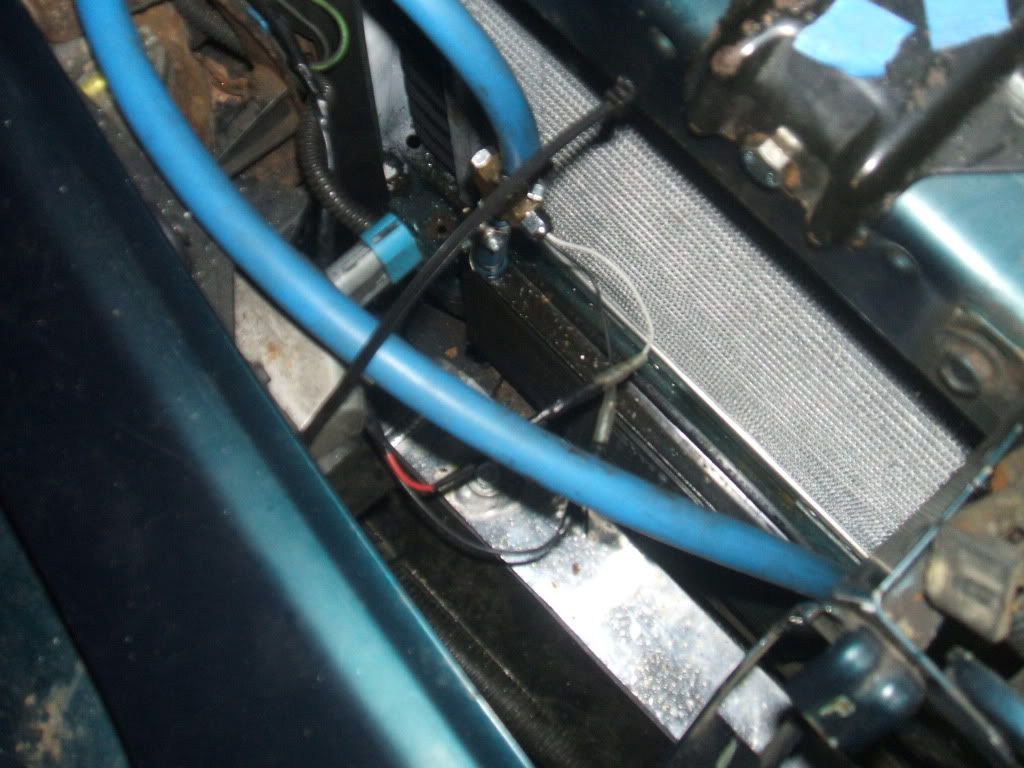

24k BTU trans cooling, ported 52mm TB (equivilant to 58mm now)

Cherry bombs with flowmaster 40's

Gasket matched the LIM to Heads and the UIM to LIM (tapered the grind 1.5" in)

3400 Top Swap (oops, not yet but soon)

Boost/Vac, Trans Temp, Oil Temp, Oil Press, WBO2 gauges

All engine bay exhaust heat wrapped, turbo blanket

HP Tuner Standard

New Cyl. Heads, new radiator, new water pump, new ignition coils/wires/plugs

New hoses, new head and LIM bolts (torqued well), HD Felpro head gaskets, modified metal LIM gaskets, new exhaust gaskets/bolts, new NBO2, new CAM/CRANK sensors, new TPS, MAF Cleaned, Fully enclosed batt trunk reloc kit, new vacuum hose kit (all blue to match) w/ connector kit. I may have forgotten a few things.

I got nearly everything done now.

Only thing I am waiting on is a turbo oil feed flange. The previous one I had snapped when tightening the braided line to it. Cheap aluminum product. Although, I do believe I over tightened.

Well, I still have to secure the gauges to the dash and steering column. But they are wired in and the wires are tucked away nicely. I had drilled a few discreet holes so the wires aren't exposed much. They enter the engine bay up behind and above the pedals, out of view.

I tapped the ignition wire from the PCM leading to the MAF Sensor (pink wire). It should work well for switched power.

The battery, I rerouted through the rear cab. The cable was placed under the seats and enter the trunk under the little trunk access/arm rest. This was to keep it away from the gas tank and rear tires, also to help protect the cable. It can't be seen in the cabin, nice.

I want to start it up so badly but I am waiting for the oil feed flange. I refuse to spin up the turbo w/o oil feed, even at idle.

Tomorrow I plan a picture day. I doubt the flange will arrive tomorrow. Probably by friday at the earliest. Darn Flat Rate Shipping USPS. I should have over nighted it. Oh well. The spare time will allow me to triple check everything.

Once the car runs, I plan to move it to my new garage where I can finish the exhaust under the body. So, yeah, I'm not done yet. But the hardest parts are over with. Welding up an exhaust under body is a cake walk compared to fitting/welding the cross-over and downpipe in the engine bay with what space I had to work with. There is enough room for the 2.5" pipe, but only that. All the bends had to be cut just right, no room for errors beyond 2-4 degrees.

I still have to build a new windshield wiper fluid container to fit. But that is also easy work. Cutting, forming and bonding plastic is much easier on the hands then steel. Though, I still am going to try searching out a container from another vehicle model that may fit. Anything at half size might work with some minor modification.

I also plan to use the A/C pressure sensor to wire the WBO2 sensor into the PCM for data logging, since I had to remove parts of the A/C system, it will be useless otherwise.

I wonder if there is a way to control the EGR valve as a turbo timer. Similar to a SC timer. When the boost has been pushed long enough, safely, the EGR could open and vent the exhaust pressure to the atmosphere. Allowing the car to remain in WOT but disable boost.

Soon, I will be starting the long road of tuning her up. Small steps and lots of research before I make any changes. I've read several tuning guides through and through many times. I am considering a 2-bar SD operating system. It would be nice to be able to measure the boost through the PCM and have it react accordingly with fuel adjustments. But, I have time to make that choice yet.

And when all is done, by spring time, I am going to give her a world class paint job. Step by step, bit by bit. One day, she will be done and riding/looking smooth as ever.

6-8 psig boost, 36 lb/hr inj, custom cross-over, cat delete, valve train cleaned well.

24k BTU trans cooling, ported 52mm TB (equivilant to 58mm now)

Cherry bombs with flowmaster 40's

Gasket matched the LIM to Heads and the UIM to LIM (tapered the grind 1.5" in)

3400 Top Swap (oops, not yet but soon)

Boost/Vac, Trans Temp, Oil Temp, Oil Press, WBO2 gauges

All engine bay exhaust heat wrapped, turbo blanket

HP Tuner Standard

New Cyl. Heads, new radiator, new water pump, new ignition coils/wires/plugs

New hoses, new head and LIM bolts (torqued well), HD Felpro head gaskets, modified metal LIM gaskets, new exhaust gaskets/bolts, new NBO2, new CAM/CRANK sensors, new TPS, MAF Cleaned, Fully enclosed batt trunk reloc kit, new vacuum hose kit (all blue to match) w/ connector kit. I may have forgotten a few things.

I got nearly everything done now.

Only thing I am waiting on is a turbo oil feed flange. The previous one I had snapped when tightening the braided line to it. Cheap aluminum product. Although, I do believe I over tightened.

Well, I still have to secure the gauges to the dash and steering column. But they are wired in and the wires are tucked away nicely. I had drilled a few discreet holes so the wires aren't exposed much. They enter the engine bay up behind and above the pedals, out of view.

I tapped the ignition wire from the PCM leading to the MAF Sensor (pink wire). It should work well for switched power.

The battery, I rerouted through the rear cab. The cable was placed under the seats and enter the trunk under the little trunk access/arm rest. This was to keep it away from the gas tank and rear tires, also to help protect the cable. It can't be seen in the cabin, nice.

I want to start it up so badly but I am waiting for the oil feed flange. I refuse to spin up the turbo w/o oil feed, even at idle.

Tomorrow I plan a picture day. I doubt the flange will arrive tomorrow. Probably by friday at the earliest. Darn Flat Rate Shipping USPS. I should have over nighted it. Oh well. The spare time will allow me to triple check everything.

Once the car runs, I plan to move it to my new garage where I can finish the exhaust under the body. So, yeah, I'm not done yet. But the hardest parts are over with. Welding up an exhaust under body is a cake walk compared to fitting/welding the cross-over and downpipe in the engine bay with what space I had to work with. There is enough room for the 2.5" pipe, but only that. All the bends had to be cut just right, no room for errors beyond 2-4 degrees.

I still have to build a new windshield wiper fluid container to fit. But that is also easy work. Cutting, forming and bonding plastic is much easier on the hands then steel. Though, I still am going to try searching out a container from another vehicle model that may fit. Anything at half size might work with some minor modification.

I also plan to use the A/C pressure sensor to wire the WBO2 sensor into the PCM for data logging, since I had to remove parts of the A/C system, it will be useless otherwise.

I wonder if there is a way to control the EGR valve as a turbo timer. Similar to a SC timer. When the boost has been pushed long enough, safely, the EGR could open and vent the exhaust pressure to the atmosphere. Allowing the car to remain in WOT but disable boost.

Soon, I will be starting the long road of tuning her up. Small steps and lots of research before I make any changes. I've read several tuning guides through and through many times. I am considering a 2-bar SD operating system. It would be nice to be able to measure the boost through the PCM and have it react accordingly with fuel adjustments. But, I have time to make that choice yet.

And when all is done, by spring time, I am going to give her a world class paint job. Step by step, bit by bit. One day, she will be done and riding/looking smooth as ever.

Comment