91, and I used my stock nuts with the rocker arms. Wasn't a problem at all. That engine is still being ran today as far as I know. It had over 50k on the rockers like that. I did eventually get a 1 piece exhaust pushrod the right length but it wasn't far off stock and intake was within spec.

Announcement

Collapse

No announcement yet.

Roller tip rockers

Collapse

X

-

I just remembered, You're probably refrencing the Crane rockers, We're talking the Comps which will require it.Originally posted by betterthanyouI never had to clearance my guides or the guides on a gen II or III for 1.6 rockers.Colin

92 Sunbird GT, 3200 Hybrid 13.99@ 95.22 (2004)

90 Eagle Talon TSi AWD 10.54 @ 129mph.

Comment

-

Yes they were Cranes but I have done it on Gen I II and III. Also like Ben is saying even though the Gen II motors in the 90's had net lash rockers systems the preload should be about the same since they are the same style of rocker arm.Originally posted by v6h.o.I just remembered, You're probably refrencing the Crane rockers, We're talking the Comps which will require it.Originally posted by betterthanyouI never had to clearance my guides or the guides on a gen II or III for 1.6 rockers.1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

-

Originally posted by betterthanyouYes they were Cranes but I have done it on Gen I II and III. Also like Ben is saying even though the Gen II motors in the 90's had net lash rockers systems the preload should be about the same since they are the same style of rocker arm.Originally posted by v6h.o.I just remembered, You're probably refrencing the Crane rockers, We're talking the Comps which will require it.Originally posted by betterthanyouI never had to clearance my guides or the guides on a gen II or III for 1.6 rockers.

The Cranes are different than the comp roller tips. With the comps you have to grind the pushrod guides for 1.6's No questions. I've only ever done the Comp Cams rockers. Have installed 2 sets of 1.52's and 3 sets of 1.6's. on varations of gen2's and 3's.

All I know is that for some reason my original 3.1L in the bird had one head with fully adjustables (probably from previous owner and maybe involving a wrecker head) and one bank had Non adjustables. I went and started putting the rockers on the car on the adjustable bank first and all was good. Started putting them on the motor on the Non-Adjustable Studs and due to there not being enough thread the rocker was completely loose in its seat (and I mean loose) Just because they're the same style of rocker doesn't mean shit. I know about 4 other guys who had the same thing with their comps, maybe it was because I was using 1.52's at the time not 1.6's??? But Luis and Adam (on v6jbody yahoo group) had the same problem Adam shimmed his stock nonadjustable rocker nut with a washer to take up the slack and clearance.

I'm just speaking from what I know first hand. :shrug.Colin

92 Sunbird GT, 3200 Hybrid 13.99@ 95.22 (2004)

90 Eagle Talon TSi AWD 10.54 @ 129mph.

Comment

-

Yes I know the thread is smaller. Its 8mm. But the main body of the stud where the pivot ball sits is 10MM1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

-

Yes, Never said that it wasn't still a M10 stud. But I refrence the non adjustables as the "M8 top nut" as that is the difference.Originally posted by betterthanyouYes I know the thread is smaller. Its 8mm. But the main body of the stud where the pivot ball sits is 10MM

Fully adjustables:

M10x1.5x9.9/M10x1x18

NON adjustables:

M10x1.5x9.9/M8x1x.32

Notice the difference in thread amounts. You have 18 on the M10's and .32 thread on the M8's. There isn't enough thread to sink down and tighten the nuts tight enough is the problem I've encountered in the past as have others.

However, yeah they are both M10 studs all the way up untill you get to the thread difference.Colin

92 Sunbird GT, 3200 Hybrid 13.99@ 95.22 (2004)

90 Eagle Talon TSi AWD 10.54 @ 129mph.

Comment

-

Yeah exactly, The net lash, possitive torque stop setup does not allow for the proper tightening down of the rocker to adjust provide the right setup. IIRC (Its been 5+ years now) there was probably about an 1/8th inch or more of clearance between my pushrod and the pushrod cup on the rocker arm when the Net lash posstive stop style nut was torqued to spec, The rocker was physically loose.Originally posted by betterthanyouOk so the net lash system is limiting your preload too much. I wonder why Ben had no problems.

Ohwell

I fully don't understand how Ben got away with this and never had issues... Doesn't make sence.

The rocker although still being a pivot ball cup style, Is very different than the OEM net lash style rocker which makes the difference in terms of you can't use that stud and nut style. Hence why I had to switch to the fully adjustable rocker arm studs and do a "zero lash preload" adjustement on mine.

There was always at least 1/8th of inch of threads protruding above my rocker nuts which took up a good 3/8ths-1/2 inch of thread on the stud itself as it was:

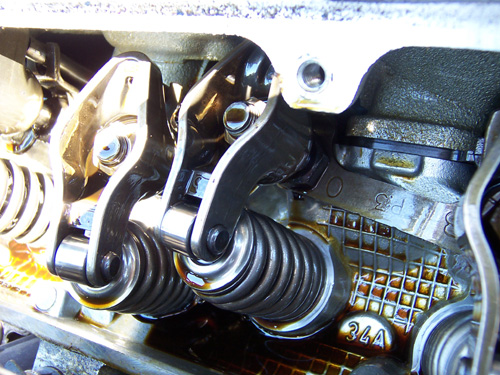

Pic of them on my gen3 heads.Colin

92 Sunbird GT, 3200 Hybrid 13.99@ 95.22 (2004)

90 Eagle Talon TSi AWD 10.54 @ 129mph.

Comment

-

yeppers! i currently have them on my 94 Z24. i too had to use the adjustable studs. thought the top half was 10 mm and what went into the head was 3/8 i think. it's been about 3.5 years since i put them on, so the memories have faded. just make sure your new studs are concentric. mine weren't and i ended up breaking 3 guide plates--yeah, there was that much side loading. fucking sealed power!!! made a claim and they never even called!! Andy

Andy

sigpic

fastest 1/8: 10.19@ 67.17

fastest 1/4: 16.16@ 82.70

62mm TB, 1.6 roller tip rockers, Ostrich 2.0, UD pulley, TB heater bypass, K&N, 180* stat, No cat, 99Grand AM dual cooling fans. 4T65E swap FDR 3.69, EP LSD, F.A.S.T. transmission controller, TransGo shift kit.

Comment

Comment