I hope that missile works very well and your intake makes the difference Can I ask is this crank an internally balanced or are you going to use a damper ?

Announcement

Collapse

No announcement yet.

300 hp N/A carb 2.8 V6 engine

Collapse

X

-

Looks to be internal balance. It has dual weights on the rear. As far as the 60 degree V6 is concerned the harmonic damper on the front has nothing to do with the balance of the crank.1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

-

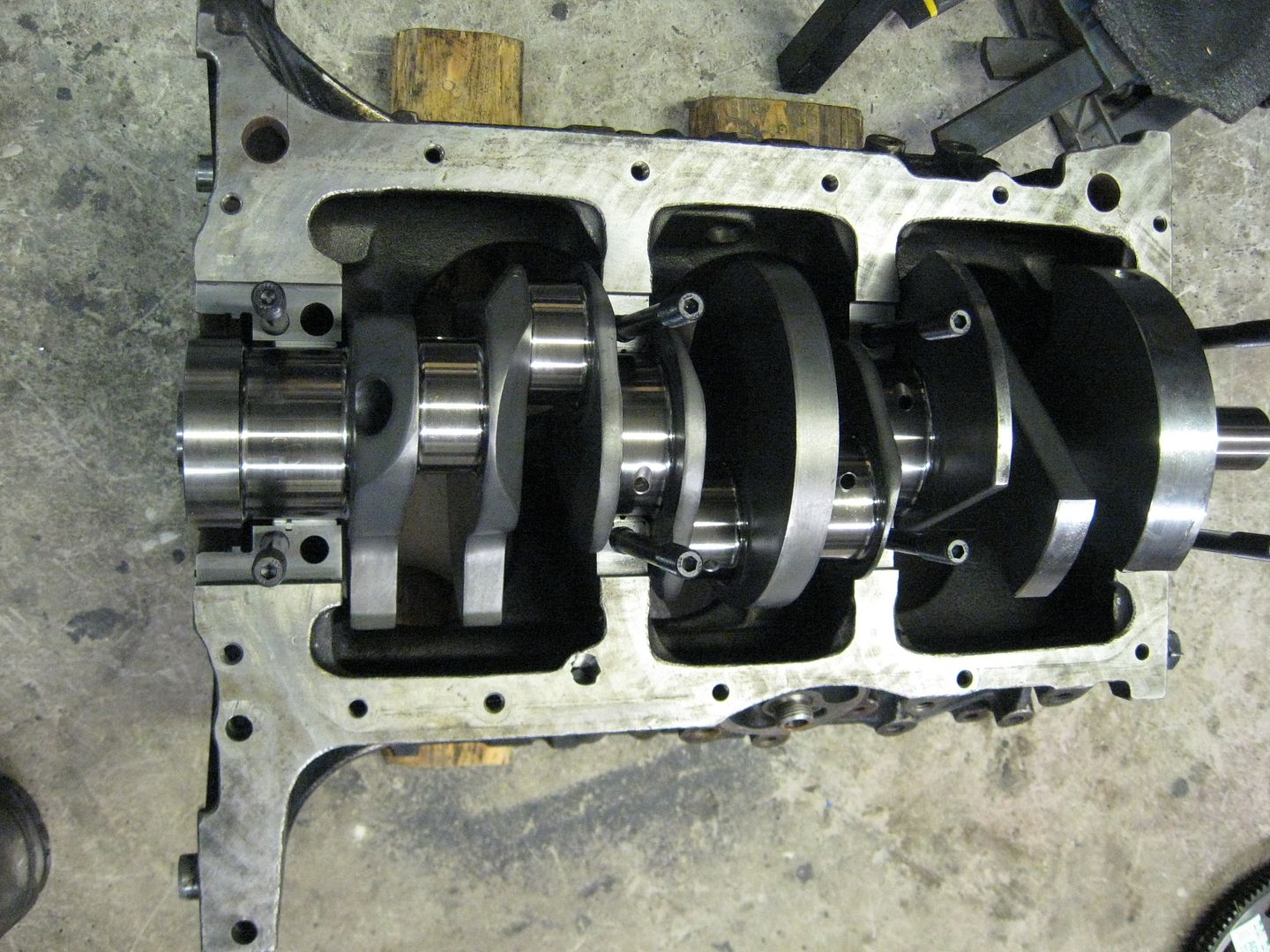

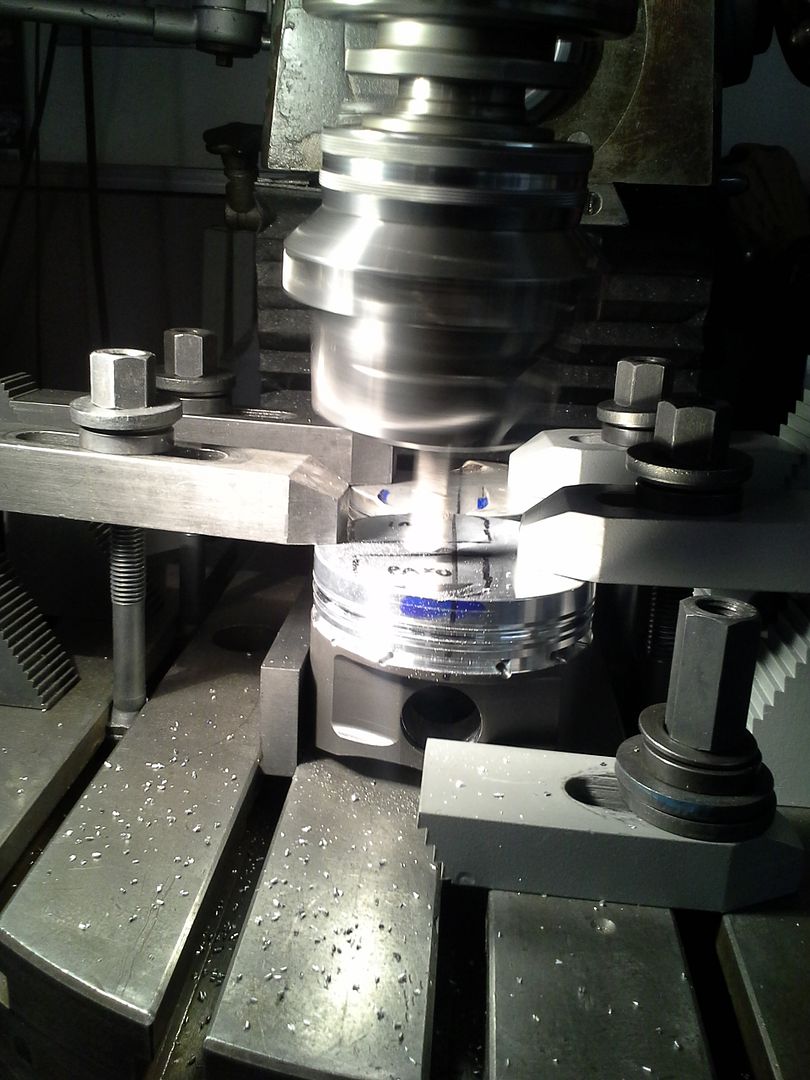

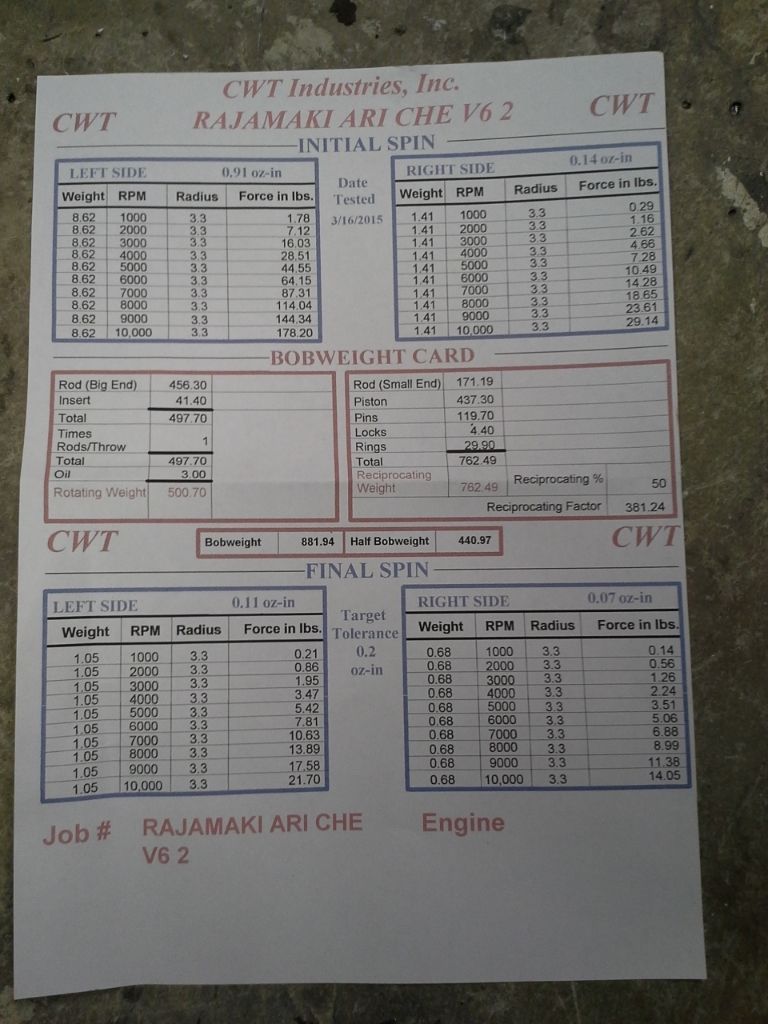

I sent Crower a sample, one stock internally balanced crank from 2.8 engine.

The idea was to make a internally balanced billet crank.

And thats what Crower did.

They seem to add two pieces of mallory metal to the crank to make it perfectly balanced.

I asked the Crower people , what kind of damper should I use with the new billet crank.

Or should I use no damper at all.

There was a ATI Super Damper in the destroyed engine.

Crower recommended ATI-dampers.

"They are good, I would use one" was the exact answer from the "expert".

Free Shipping - ATI Super Damper Standard Harmonic Balancers with qualifying orders of $109. Shop Harmonic Balancers at Summit Racing.

Free Shipping - ATI Super Damper Standard Harmonic Balancers with qualifying orders of $109. Shop Harmonic Balancers at Summit Racing.

Last edited by veekuusi; 12-31-2014, 12:26 PM.

Last edited by veekuusi; 12-31-2014, 12:26 PM.

Comment

-

ATI does make good dampers. Elastomer is the way to go and it seems by the description they have 2 ring diameters supported by an elastomer so it will not be tuned to just one frequency, which is good. That being said the short crank of the V6 is not prone to huge harmonic problems (like a longer V8, or worse an I6, crank) but any engine running on the street or sustained RPM racing really needs to have a damper. Drag racers don't need one because the RPM's are always changing the entire run so the variable frequency never lets resonance set up. Since your racing the SFI rating of the ATI damper may be a requirement too. A stock one is no good for some sanctioning bodies. The cast outer ring may explode without warning at 7000RPM.1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

-

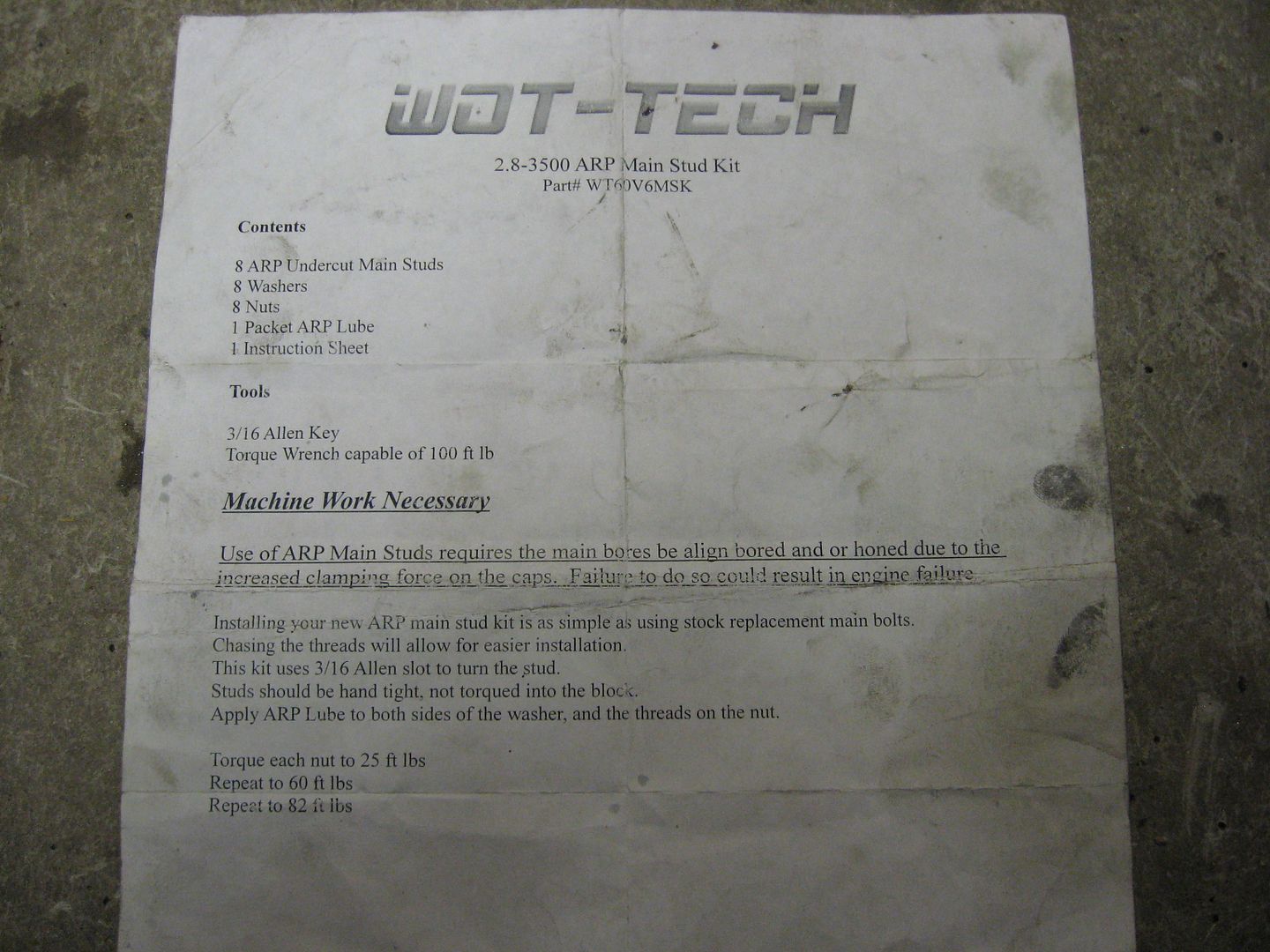

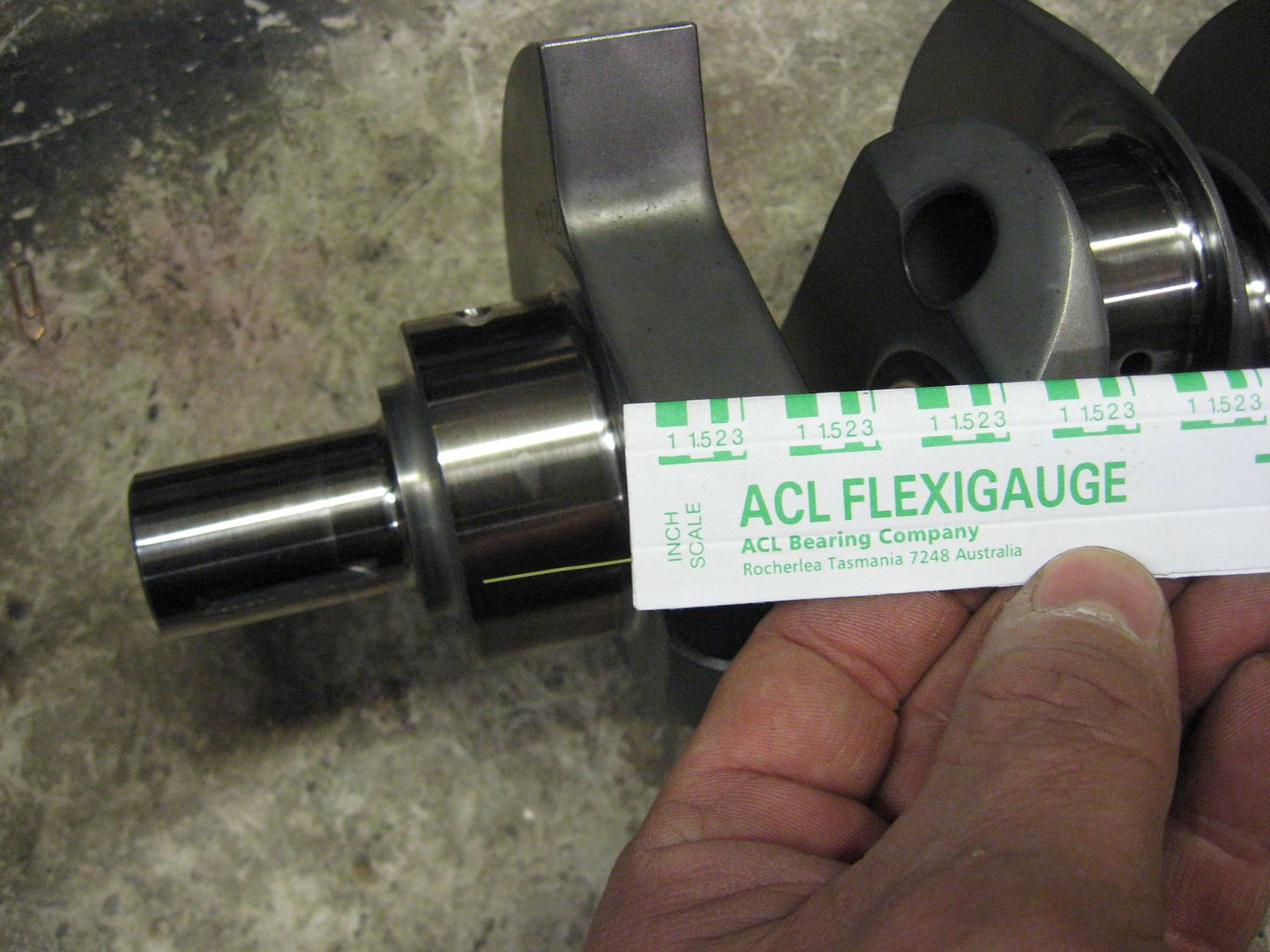

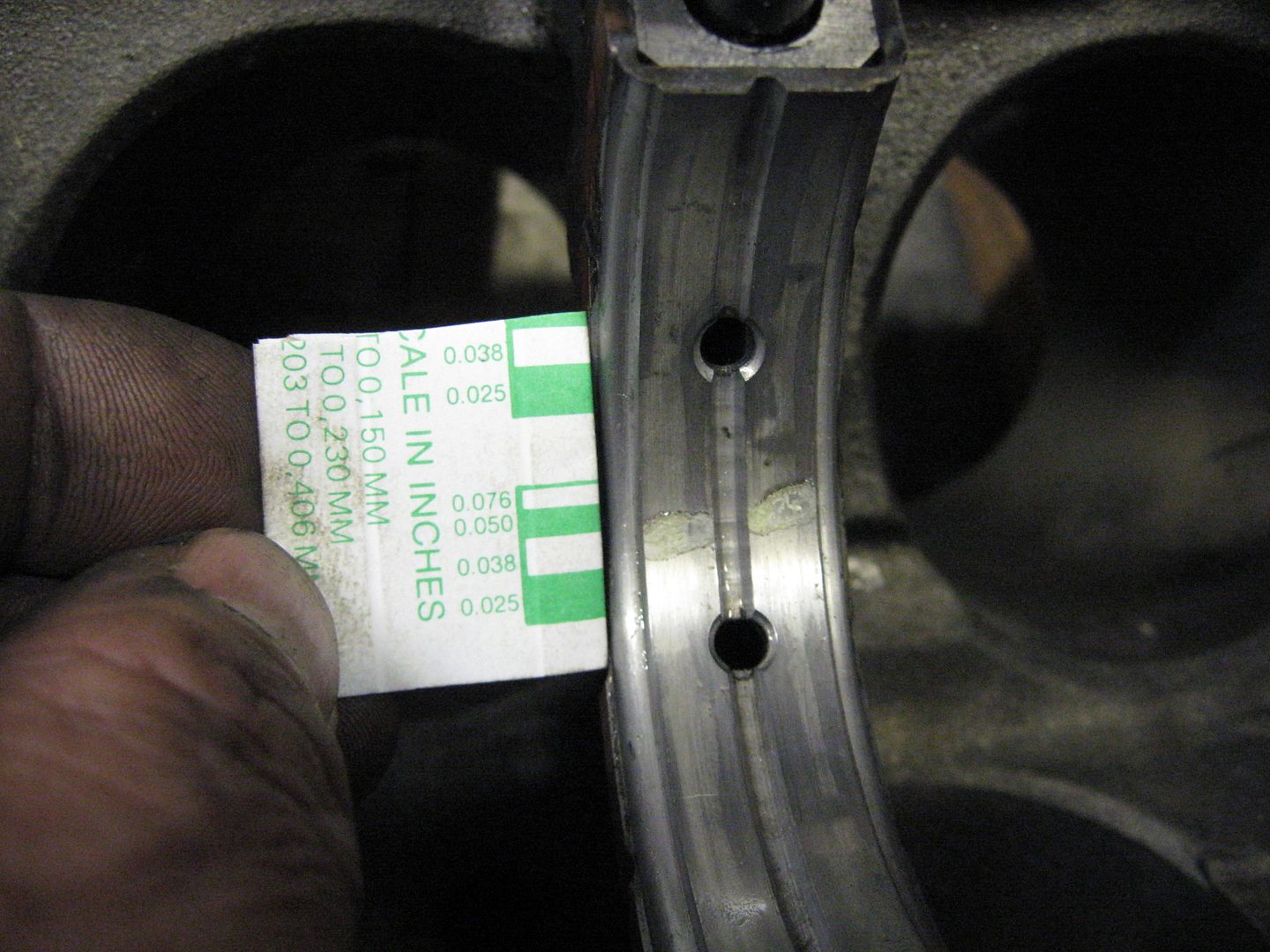

That's .0015"... That's good for a race engine, but I wouldn't want it any tighter than that. Have you had the mains bored or honed? If you torque all the main caps down, how much torque does it take to rotate the crankshaft?Current:

\'87 Fiero GT: 12.86@106 - too dam many valves; ran 12.94 @ 112 on new engine, then broke a CV joint

\'88 Fiero Formula: slow and attention getting; LZ8 followed by LLT power forthcoming

\'88 BMW 325iX: The penultimate driving machine awaiting a heart transplant

Gone, mostly forgotten:

\'90 Pontiac 6000 SE AWD: slow but invisible

Comment

-

Everything has been done by the book.Originally posted by Will'sFiero View PostThat's .0015"... That's good for a race engine, but I wouldn't want it any tighter than that. Have you had the mains bored or honed? If you torque all the main caps down, how much torque does it take to rotate the crankshaft?

I mean by the Benīs book.

I do not know about the torque but the crank rotates quite easily.

You better check the video:

Last edited by veekuusi; 01-04-2015, 02:20 AM.

Comment

-

Its tight but do you have a mic and telescoping gauge you can measure with? Plastigauge is a great double checking tool when doing a re and re but not good enough for a race motor.1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

-

I know a few professional engine builders who build high performance engines and use Plastigauge. It's really the only way to know actual clearance, when things are torqued down.Originally posted by 23TrackroadsterV6 View PostPlastigauge is for lawn mower engines! Micrometers should be used on high performance engines.

Comment

-

You mic the journals and then you use a mic to verify your bore gauge and check the ID of the bearing when torqued in place, obviously leaving the crank out to have access to the bearing. I just did this for my engine and verified the measurements with plastigauge.

My average main journal clearance was 0.0028 measured. I was instructed by a shop that it's better to be on the high side of the clearance with what I plan to do with it. Range is 0.0008-0.0025 for a street car factory build.

For reference my crank has a supposed 40k on it and the block is a 4k block. I'm using brand new OEM GM Bearings. Mic'd the journals at 2.6475, 2.6470, 2.6475, 2.6470 Bearing's installed and torqued came up at 2.650, 2.6502, 2.6502, 2.650

Basics

Last edited by 3400-95-Modified; 02-25-2015, 11:00 AM.

Got Lope?

3500 Build, Comp XFI Cam 218/230 .050 dur .570/.568 lift 113LSA

Fully Balanced, Ported, 3 Angle Valve Job, 65mm TCE TB, S&S Headers.

Stage-1 Raybestos/Alto 4t60e-HD, EP LSD, 3.69FDR

12.61@105 Epping NH Oct 2015 Nitrous 100shot (melted plugs) 13.58@98.8 N/A 3200LBS

Comment

-

Comment