Announcement

Collapse

No announcement yet.

300 hp N/A carb 2.8 V6 engine

Collapse

X

-

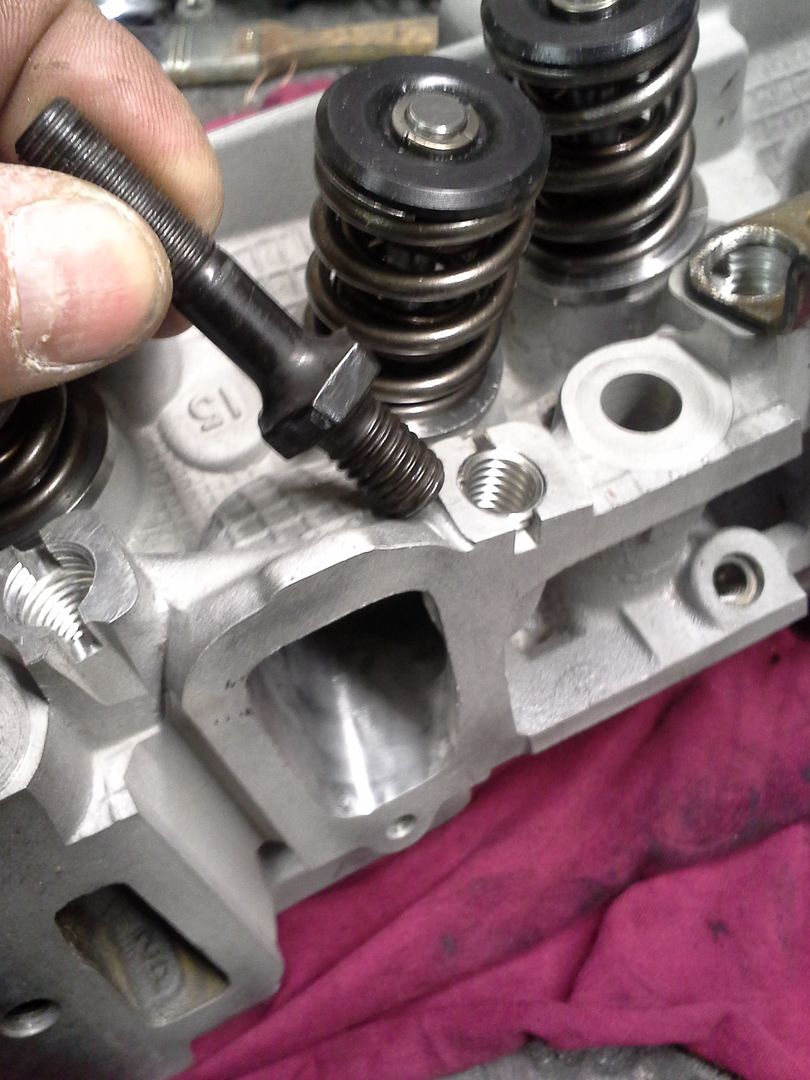

You might want to look into Time-Serts, as rocker studs are a high load rather than high cycle application. Helicoils tend to pull out on high load apps (e.g. head bolts), Time-Serts tend to unscrew on high cycle apps.

Time-Serts install into the same STI-tapped holes as helicoils, so switching isn't a big deal.

Leave a comment:

-

Guest repliedNice!

Guest repliedNice!

Leave a comment:

-

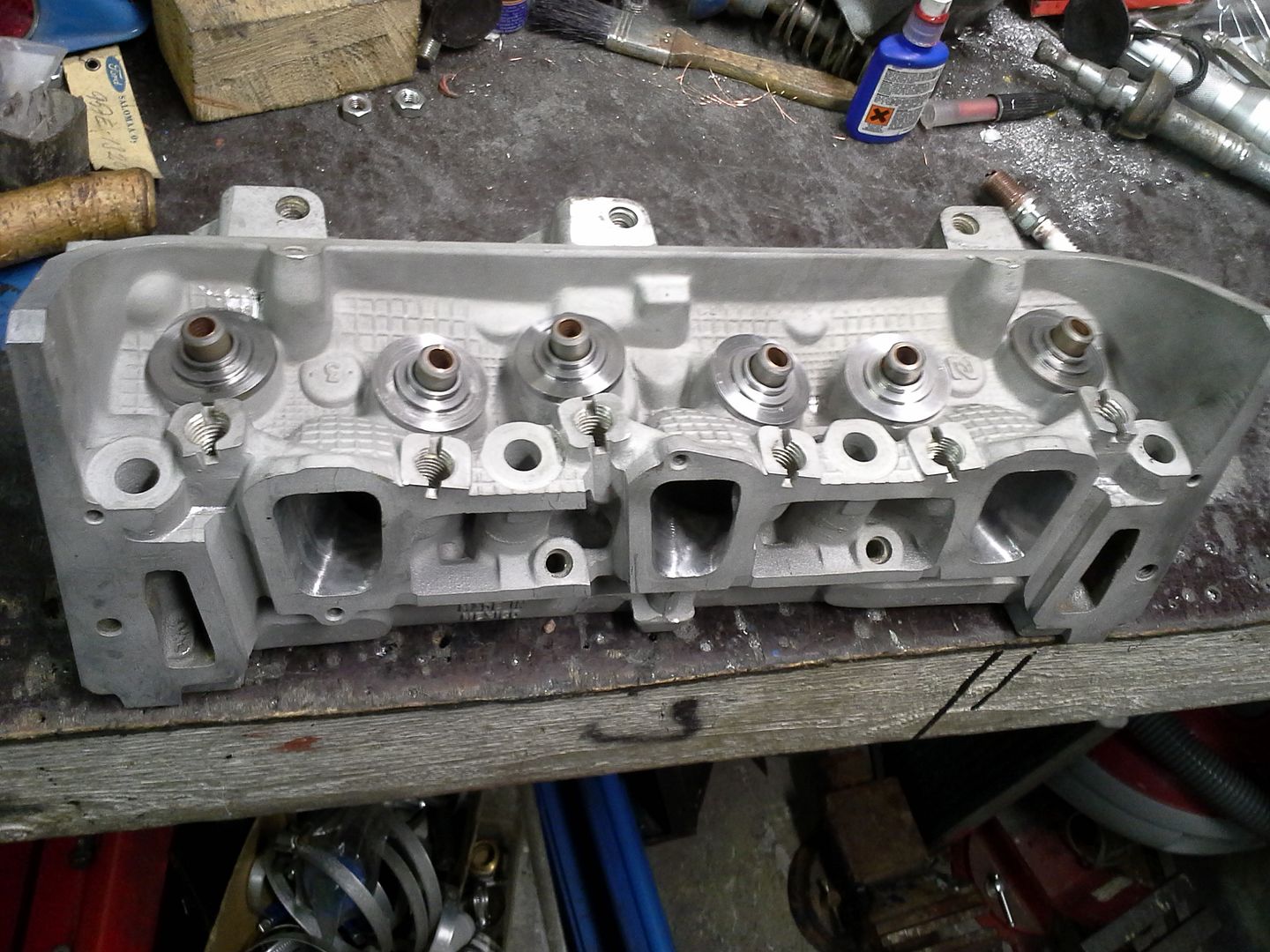

Cylinder head assembly.

ARP rocker arm studs 7/16 bottom and 3/8 top.

And 7/16" helicoils.

Leave a comment:

-

Oh yes, I see that now. Thank you. Damn it's been a long time.... wish I could do another build.

Leave a comment:

-

I think he just tapered the end of it and didn't drill it out as it appears. The one on the left also appears to not have a spirol-lox in yet so that is deceiving in appearance.

Leave a comment:

-

Cool man, makes me feel better. You know I'm a fan! Hope that wrist pin holds up, looks a bit thin.

Leave a comment:

-

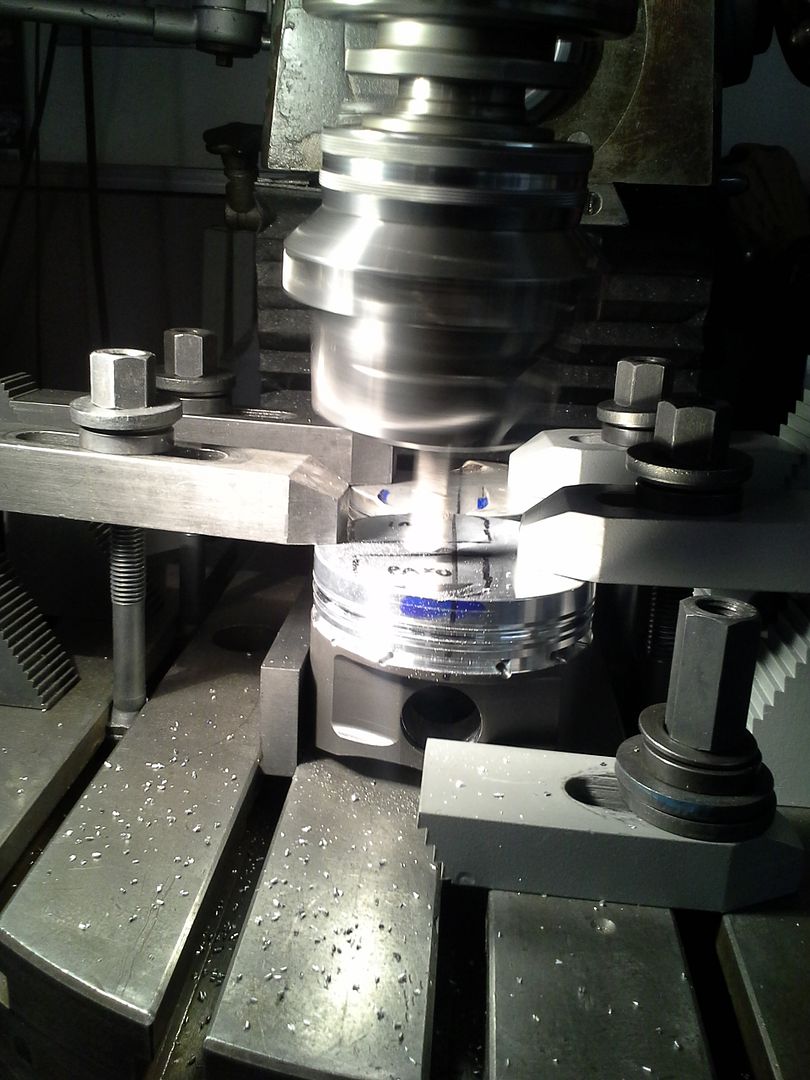

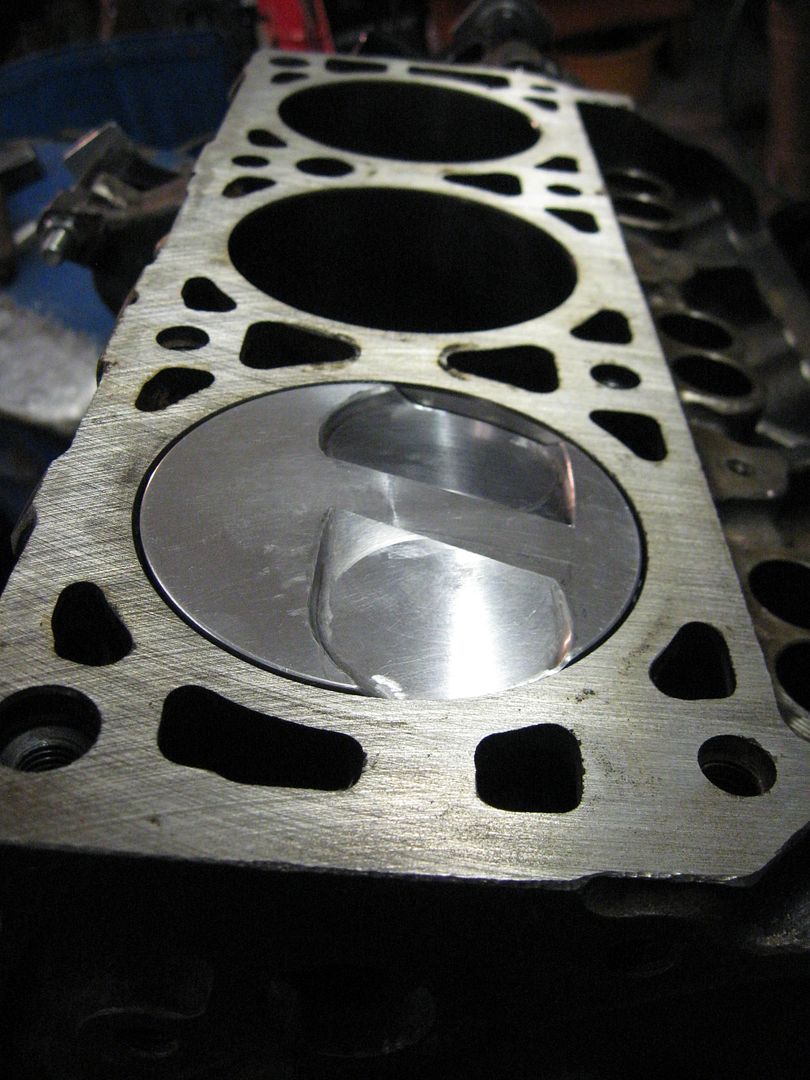

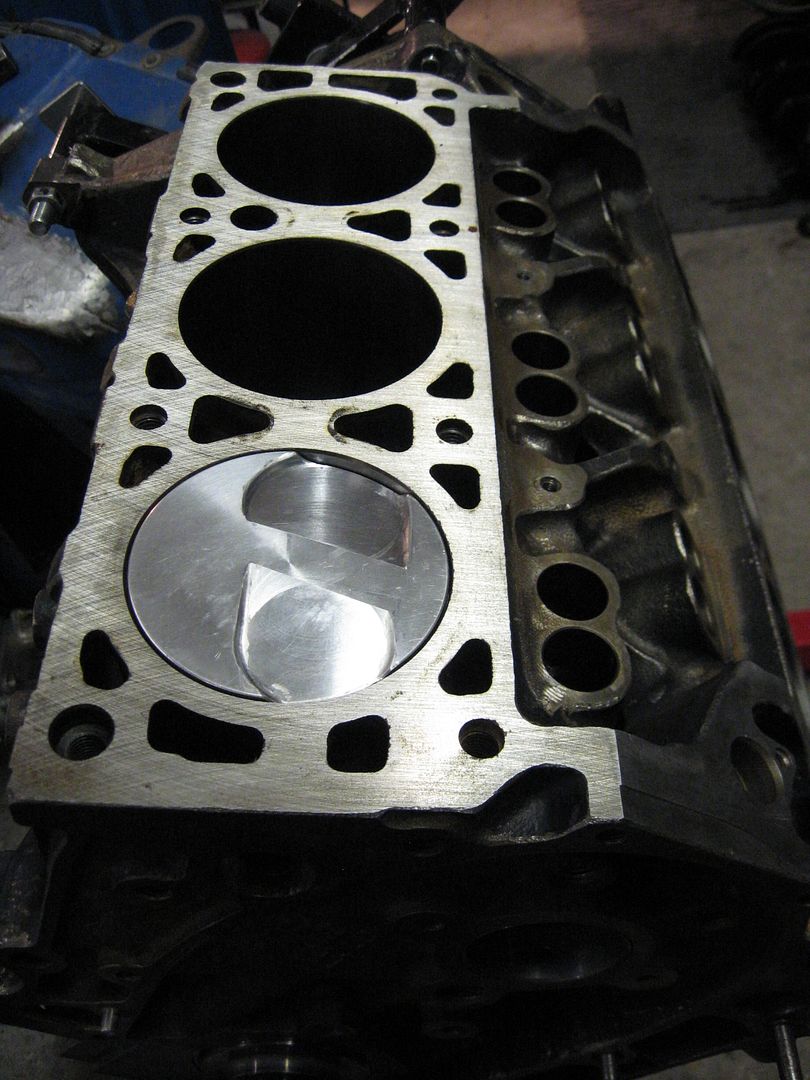

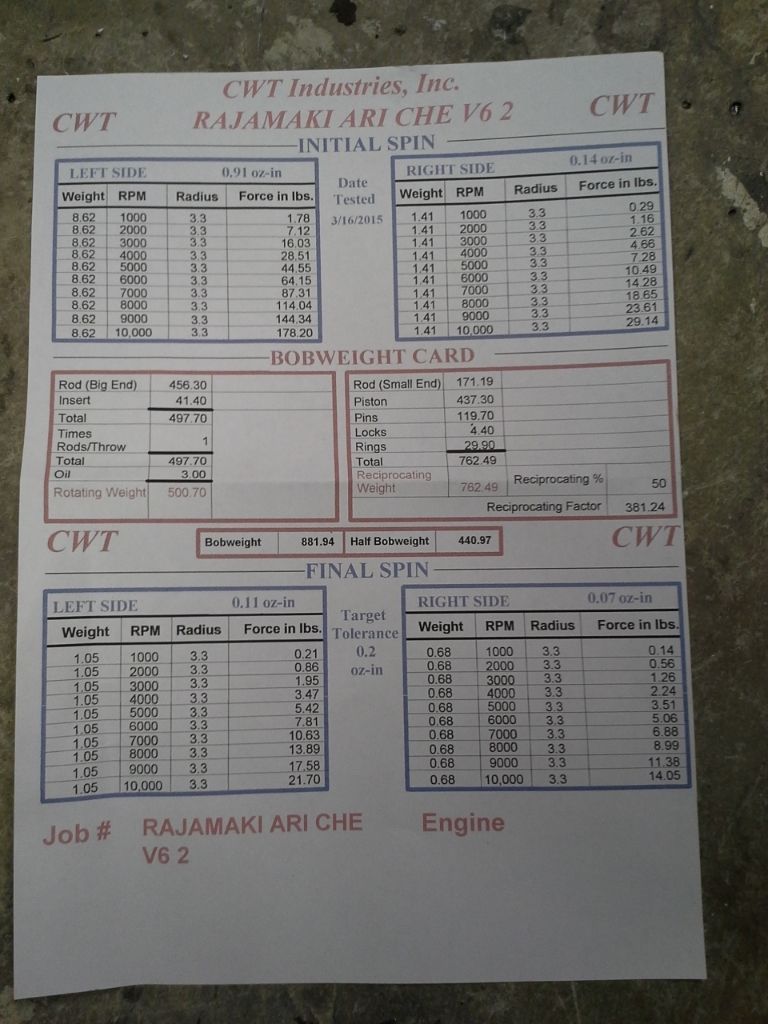

2 new pistons came out from Diamond couple of grams heavier than the old 4 ones.Originally posted by Purple pit View PostAll the pistons came out to be the same weight? Planning to check the balance of the whole assembly?

All the measurement are the same, but they did weight more than the old ones.

But we took material out of the wrist pins of those 2 pistons to get

all the pistons and wrist pins and rings to the same weight.

All the 6 connecting rods weight the same ,tolerantly in 1 gram.

And the balance of the whole assembly has been checked, it is OK.

You can see the new piston in the right ,wrist pin has been lightened (to reduse weight).

Leave a comment:

-

All the pistons came out to be the same weight? Planning to check the balance of the whole assembly?

Leave a comment:

-

Damn that sucks! Best of luck getting them. Every thing I touch with my engine is turning into a crazy project as well lol gotta love building a performance 60° v6

Leave a comment:

-

I was thinking of putting the pistons to the block this weekend.

First you have to check the piston ring caps of course.

I was taking the rings out of the bag, I found out that there were only 4 rings.

4 top rings, 4 second groove rings and 4 oil rings.

I ordered a FULL SET OF NEW RINGS.

I checked the order, I did not mention that I have a 6 cylinder engine,

some one has thought I have a 4 cylinder engine.

I should have cheched the order earlier more carefully.

Now I have to get 2 sets of rings here asap.

Maximum one week.

They are Total Seal rings.

Lets see what I can do.

I do not want to put old rings to 2 pistons .

Last edited by veekuusi; 03-22-2015, 08:57 AM.

Last edited by veekuusi; 03-22-2015, 08:57 AM.

Leave a comment:

-

I am sorry not to have put input to this thread more often.

But I have been busy with other things.

Not so much have been going on in my garage.

The valve relief have been done to the 2 new pistons.

And I am working with the 3400 heads

Last edited by veekuusi; 03-09-2015, 11:41 AM.

Last edited by veekuusi; 03-09-2015, 11:41 AM.

Leave a comment:

-

You mic the journals and then you use a mic to verify your bore gauge and check the ID of the bearing when torqued in place, obviously leaving the crank out to have access to the bearing. I just did this for my engine and verified the measurements with plastigauge.

My average main journal clearance was 0.0028 measured. I was instructed by a shop that it's better to be on the high side of the clearance with what I plan to do with it. Range is 0.0008-0.0025 for a street car factory build.

For reference my crank has a supposed 40k on it and the block is a 4k block. I'm using brand new OEM GM Bearings. Mic'd the journals at 2.6475, 2.6470, 2.6475, 2.6470 Bearing's installed and torqued came up at 2.650, 2.6502, 2.6502, 2.650

Basics

Last edited by 3400-95-Modified; 02-25-2015, 11:00 AM.

Leave a comment:

Leave a comment: