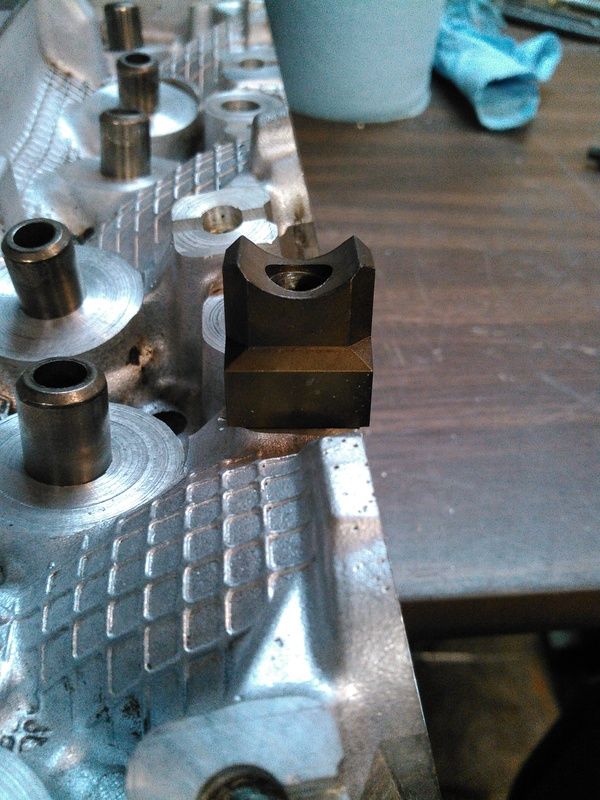

Spent a little time on this today, and the wipe pattern is too far to the exhaust side by 4mm. Ideally, the same height rocker pedestal would be used but the rocker bolt would move backwards away from the valve 4mm. This is a viable solution only if offset sleeves are used and smaller-diameter rocker arm bolts are used. Getting a full 4mm out of an 8mm bolt though...not gonna happen that way.

Using the stock 3500 pedestals, an LS1 rocker arm will strike the pedestal at 0.510" of valve lift. This is a fixable problem.

Dropping the rocker arm pivot down could work, but causes other issues due to the location of the pushrod cup, which is just as important as the valve tip. Also, dropping the pivot down far enough to pull the tip 4mm is *probably* unworkable.

Reshaping the rocker arm tip would work-but then will change the ratio of the rocker arm. Could possibly end up with 1.68 ratio, which isn't much gain, not really enough to justify the work involved.

Obviously changing the valve angle is possible and would work fine, but again...work vs gain is low.

Using the stock 3500 pedestals, an LS1 rocker arm will strike the pedestal at 0.510" of valve lift. This is a fixable problem.

Dropping the rocker arm pivot down could work, but causes other issues due to the location of the pushrod cup, which is just as important as the valve tip. Also, dropping the pivot down far enough to pull the tip 4mm is *probably* unworkable.

Reshaping the rocker arm tip would work-but then will change the ratio of the rocker arm. Could possibly end up with 1.68 ratio, which isn't much gain, not really enough to justify the work involved.

Obviously changing the valve angle is possible and would work fine, but again...work vs gain is low.

Comment