So as some of you know I bought Double0bu's car that he has for sale in the classifieds. He had indicated that he got it all back and after 45 minutes of run time the engine developed a rod knock.

Engine Mods List:

3500 engine complete tear down and inspection,new rings and bearings,multi angle valve job,1280 cam (old grind), tce double roller,ported upper and lower intake,tce 65mm tb,tce crank trigger,S&S ceramic coated headers,cold air intake,lt1 lifter springs,180 stat,LS1 MAF, ARP Rod Bolts, Aeromotive 340 fuel pump, ect. this is all new and assembled by a profesional shop.

Trans:

4t45e from 03 ga ,completely rebuilt, raybestos blues,LSD from engineered tech,3.91 final drive ratio,3000 stall converter

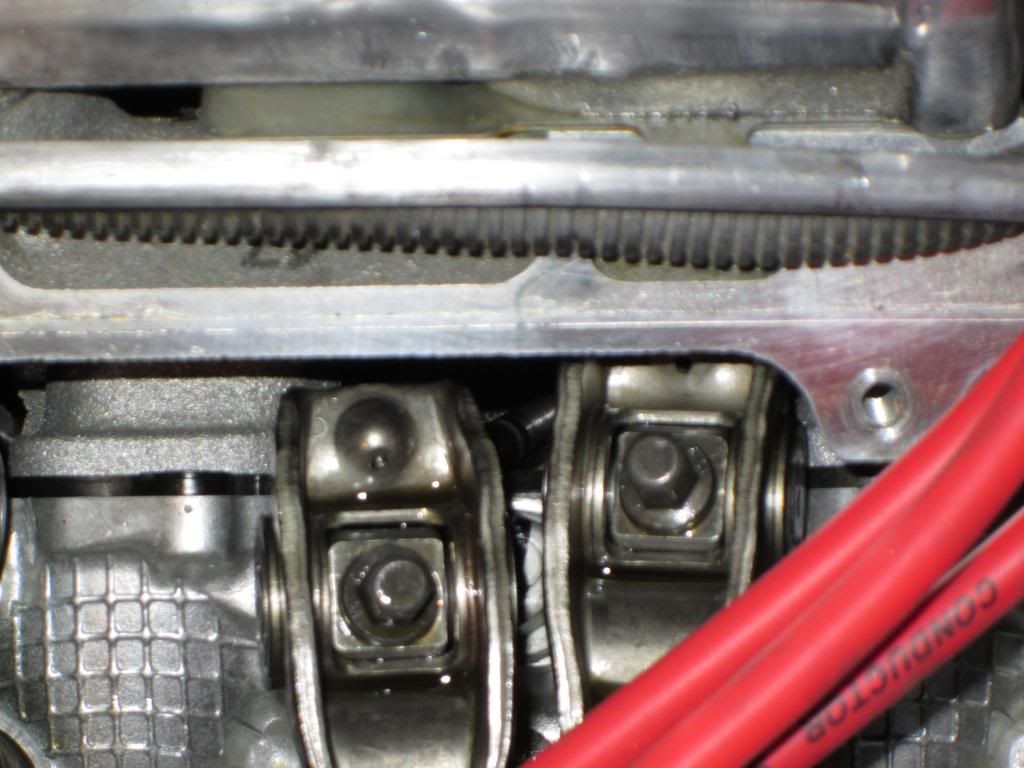

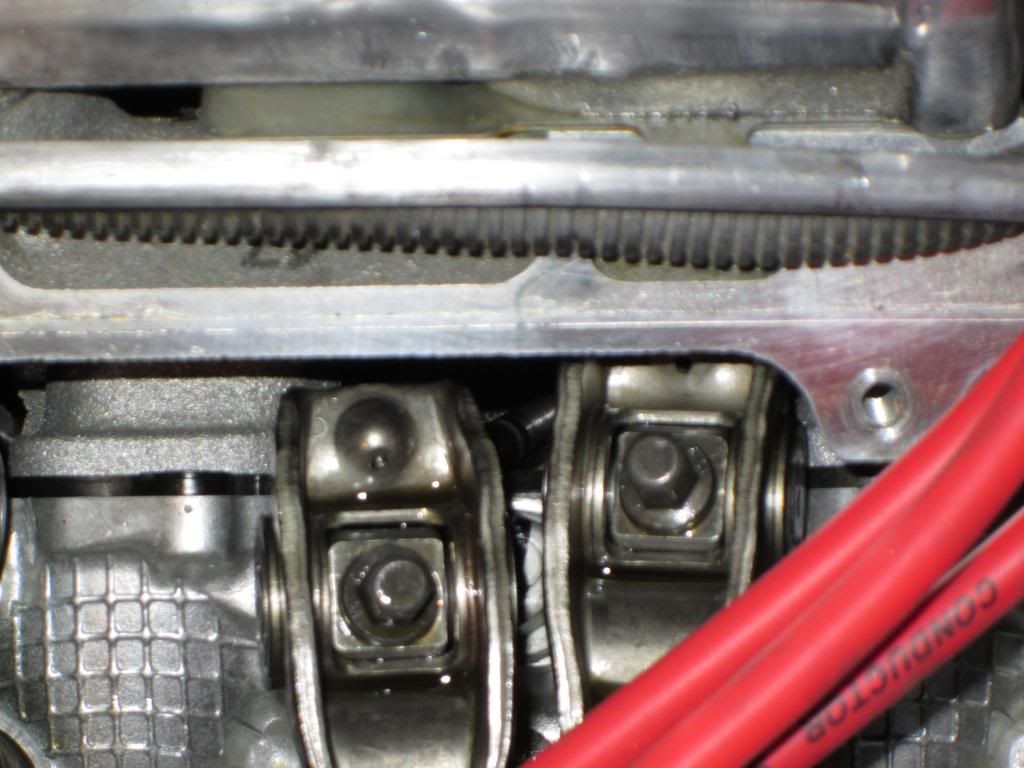

I got the car over to my house on Thursday and when I pulled the valve cover, all springs were good, rocker arms were tight, but the intake pushrod on cylinder #5 had popped out.

I pulled the rocker arm and checked to see if the pushrod was bent, which it was not. I proceeded to put it back together started it for a short time without the valve cover, which it started and was splashing a little oil on the headers. So I shut it down and put the valve cover back on so I could let it run. The engine runs, and sounds sounds good, until it drops down to low RPM. When it drops to lower rpm the engine surges and audible knock occurs. Bump up the RPM to about 1000-1200 and it goes away instantly. I took a video of this in hopes to get some ideas/advice before I tear into it any further.

Click Image For Video

So what do you think it is.... Lifter or Rod Bearing?

I am leaning toward a collapsed lifer due to the following:

The knock sounds like it is coming from cylinder 5, upon initial inspection cylinder 5 intake pushrod had popped out, however rocker arms were tight and valve springs were good. Everything is put back and it still knocks but the knock goes away with higher at 1000-1200 rpm. Lastly one of the mods that was done was LT1 lifter springs, potentially meaning that it did not get put back together properly.

Engine Mods List:

3500 engine complete tear down and inspection,new rings and bearings,multi angle valve job,1280 cam (old grind), tce double roller,ported upper and lower intake,tce 65mm tb,tce crank trigger,S&S ceramic coated headers,cold air intake,lt1 lifter springs,180 stat,LS1 MAF, ARP Rod Bolts, Aeromotive 340 fuel pump, ect. this is all new and assembled by a profesional shop.

Trans:

4t45e from 03 ga ,completely rebuilt, raybestos blues,LSD from engineered tech,3.91 final drive ratio,3000 stall converter

I got the car over to my house on Thursday and when I pulled the valve cover, all springs were good, rocker arms were tight, but the intake pushrod on cylinder #5 had popped out.

I pulled the rocker arm and checked to see if the pushrod was bent, which it was not. I proceeded to put it back together started it for a short time without the valve cover, which it started and was splashing a little oil on the headers. So I shut it down and put the valve cover back on so I could let it run. The engine runs, and sounds sounds good, until it drops down to low RPM. When it drops to lower rpm the engine surges and audible knock occurs. Bump up the RPM to about 1000-1200 and it goes away instantly. I took a video of this in hopes to get some ideas/advice before I tear into it any further.

Click Image For Video

So what do you think it is.... Lifter or Rod Bearing?

I am leaning toward a collapsed lifer due to the following:

The knock sounds like it is coming from cylinder 5, upon initial inspection cylinder 5 intake pushrod had popped out, however rocker arms were tight and valve springs were good. Everything is put back and it still knocks but the knock goes away with higher at 1000-1200 rpm. Lastly one of the mods that was done was LT1 lifter springs, potentially meaning that it did not get put back together properly.

Comment