Originally posted by Superdave

View Post

Announcement

Collapse

No announcement yet.

stud upgrade for factory rockers

Collapse

X

-

what about integrating something like the older 3100 heads. if we could get longer studs for the stock rockers it could work.

sigpic

99 Grand Am GT

3400/3500 -Solid trans mount--TCE 65mm T-body---85mm LS2 maf---1 1/4' TCE intake spacers with 3400 upper--SLP Catback with flowmaster 80--TOG headers

Modded 3400 lifters with LT1 springs---Comp Cams 26986 Springs

1357 cam 227 233 .050 dur 515 515 lift 112 lsa

15.232@88.85mph on stock 3400---New time to come

-

I think those are simply pushrod guides. Perhaps to help with pushrod bending/vibration at high RPM?

Though something similar might be do-able.

One thing interesting about the Gen III+ heads they have the steel mounting pads for the rockers. LS7s which use similar rockers do not have this, nor do the older style. They rely on the stud to transmit all the bending. If torqued properly the Gen III+ rocker mount pedestals help to transmit some of the bending to the base at the head.

Comment

-

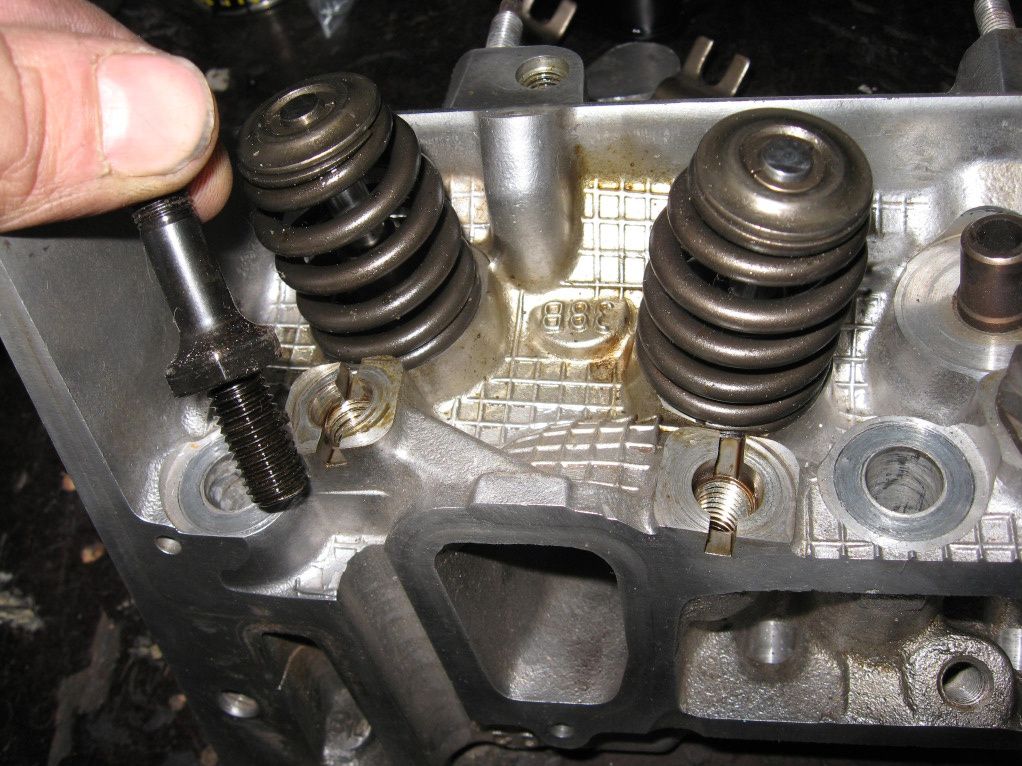

The gen2/early 3100 guideplates would help a little but the majority of the problem is at the top of the stud.

longer studs and something like this is going to be the answer...

Now, to talk Marc into making them, and some valve covers that they'll fit under.. haha

Comment

-

find longer headed bolts with a threaded insert on the heads of them, bolt them on, fill the valve cover with clay, remove, trim out clearance and unnessisary weight, make a negetive, cast it, drill holes to run bolts into fancy rocker bolts, and done. the only way to accomplish this is to make the valve cover the gurdleLast edited by bob442; 02-03-2012, 10:13 AM.

Comment

-

i'd be interested in a set.sigpic

99 Grand Am GT

3400/3500 -Solid trans mount--TCE 65mm T-body---85mm LS2 maf---1 1/4' TCE intake spacers with 3400 upper--SLP Catback with flowmaster 80--TOG headers

Modded 3400 lifters with LT1 springs---Comp Cams 26986 Springs

1357 cam 227 233 .050 dur 515 515 lift 112 lsa

15.232@88.85mph on stock 3400---New time to come

Comment

-

[QUOTE=Superdave;450187]The gen2/early 3100 guideplates would help a little but the majority of the problem is at the top of the stud.

longer studs and something like this is going to be the answer...

Superdave, you might be on to something here becouse the stud gridle in the picture does not use longer studs. The gridle is gripping the top of the adjusters. The rocker stud is normal size but the rocker arm nut/lash adjuster has a extended top for the girdle. Have not looked, maybe someone makes one in a 10 mm size.

Comment

-

how about rocker studs that are long enough to make it through the valve cover, then lock nut the studs to the valve cover? :PsigpicHow to make High performance Emissions:

A "true" High flow converter, straight pipe.

Low/No flow EGR valve, block off plate.

Carbon canister and purge valve mod, place in large 30 Gallon can, cover, and place curbside, the city will do the rest.

PCV valve and vent tube, reroute to exhaust to dump where it belongs, on the ground. Or add breathers and let it all free.

Comment

-

How about something like a twin shaft. Like these

No need for any girldes, very stable, and possibly easy to make work with a stock rocker....and you can use studs that would not have to be machined down and no guide plates.....Just sayin. Or you can go the old school way that scorpion did with their LS rockers and use a pedestal with flats and have a piece of steel quite like the guide plates hold them together so they do not spin or move. No need for guideplates or extra machining and very stable. And possibly more cost effective.

This is the new pedestal they make for the LS3/L92 style heads, a slight improvement on their older design of a pedestal and a holder plate.

This is roughly what the old pedestal looked like, you can clearly see the flats on them where the U channel sits.

Comment

-

Not true on the as stable as shaft rockers, but they work pretty good. Honestly I have never heard of properly torqued rockers coming out. EVER. On a 660. I have messed up a few and helicoiled them before. No prob. Honestly Helicoil is prob the best. Edelbrock helicoils their race heads before you buy them IIRC.Originally posted by NateD4 View PostWhy do people not think the Gen III, IV, and V rockers aren't stable?

The steel mounting pedestals are fairly stable. Probably as stable as shaft mount rockers.

Comment

-

Helicoils are great if you have enough material thickness for them. I'm not sure on Gen V heads because I haven't investigated yet. But overall the spacer blocks will be more stable than rocker studs. People shouldn't 'upgrade' to rocker studs if they have spacer blocks. Even replacing bolts is 'gimmicky' as the aluminum is probably the weak point unless you have proper thread length (thread engagement).

Comment

-

How did those solid lifters and studs I sold you work out?Originally posted by veekuusi View Post- stock 3400 = bottom M10 , top M10

- aftermarket roller rockers = bottom M10 , top 3/8

- my project = bottom 7/16 , top 3/8 (ARP)

I am updating my rocker arm studs to longer ones .

Because probably need longer valve springs and therefore longer valves.

Have to drill the hole in the head larger and put a helicoil insert.

I can not do the job in my garage , my friend is doing that job.

That is why no pictures yet.

Most difficult is to drill the new larger hole downright.

There is not much material round the hole.

The helicoil insert makes it stronger , but it can still break down , because the aluminum

fall to pieces.

I understund there is not problem with the studs in normal usage.

But when you have high revving engine with heavy valve spring loads, that is

when this maybe an issue.

I am working on a stud girdle also.

That is not brought to the desired final state yet.

Took a break from working on the car. Got some better tools, got a better shop, got a better job... Its time to burn metal!

Took a break from working on the car. Got some better tools, got a better shop, got a better job... Its time to burn metal!

Comment

-

Any idea what kind of natural frequency you are seeing from that setup?

I contemplated getting rocker studs but I think the removal of additional material around the aluminum could weaken things at least on the Gen 5 heads. Adding a helicoil will probably cut down on the life of the bolt hole a bit.

Also what kind of lift are you running that you need longer springs? I'm setting my 3900 build up for 8500 RPM and am looking at the PAC 1519 springs which are an LS1 Beehive with 360 lbs open force (about 320-330 with the valve lift I'm running). As it is my preliminary analysis shows that I probably wont' need much more than that for 8500 RPM operation.

Comment

Comment