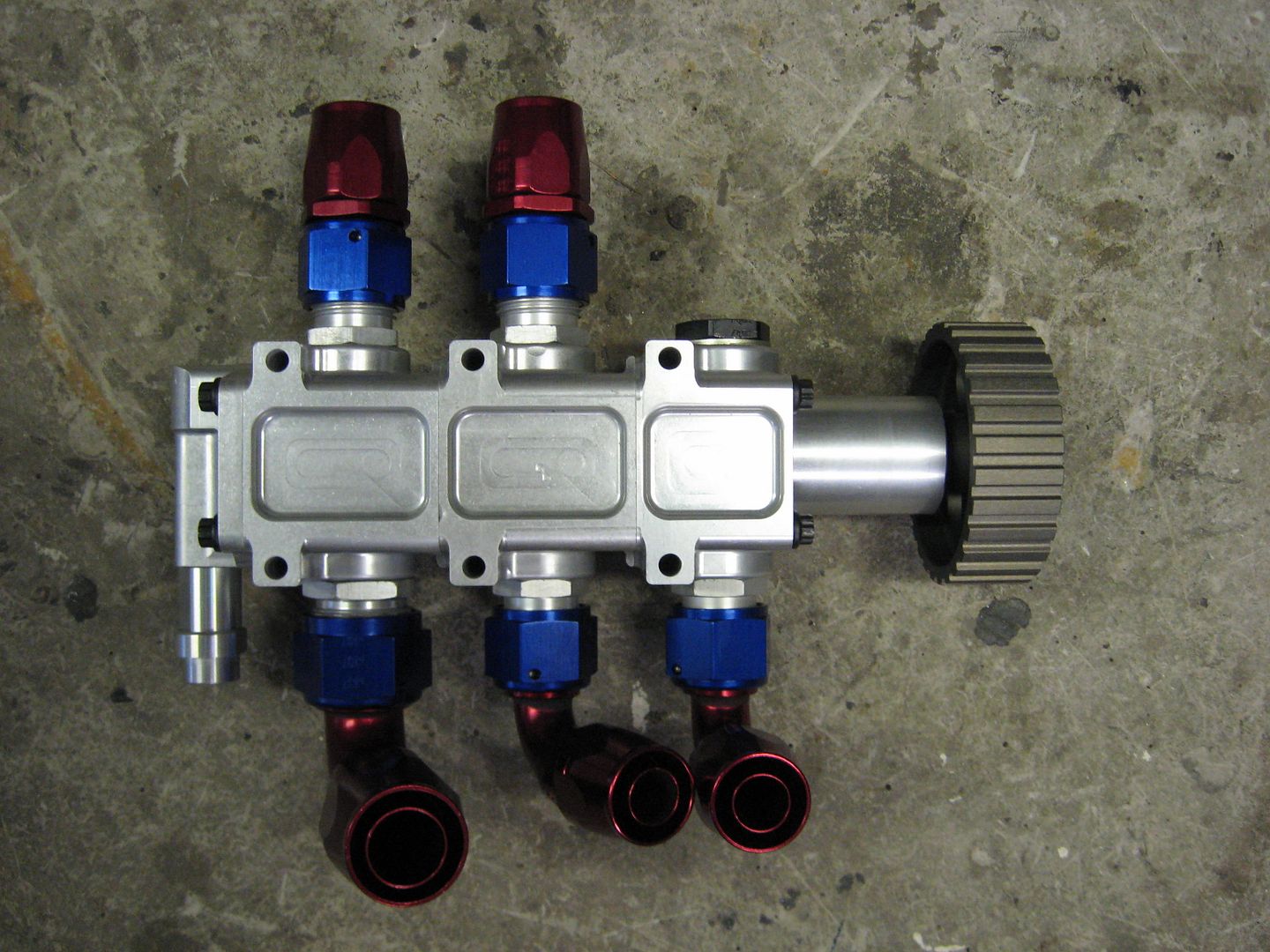

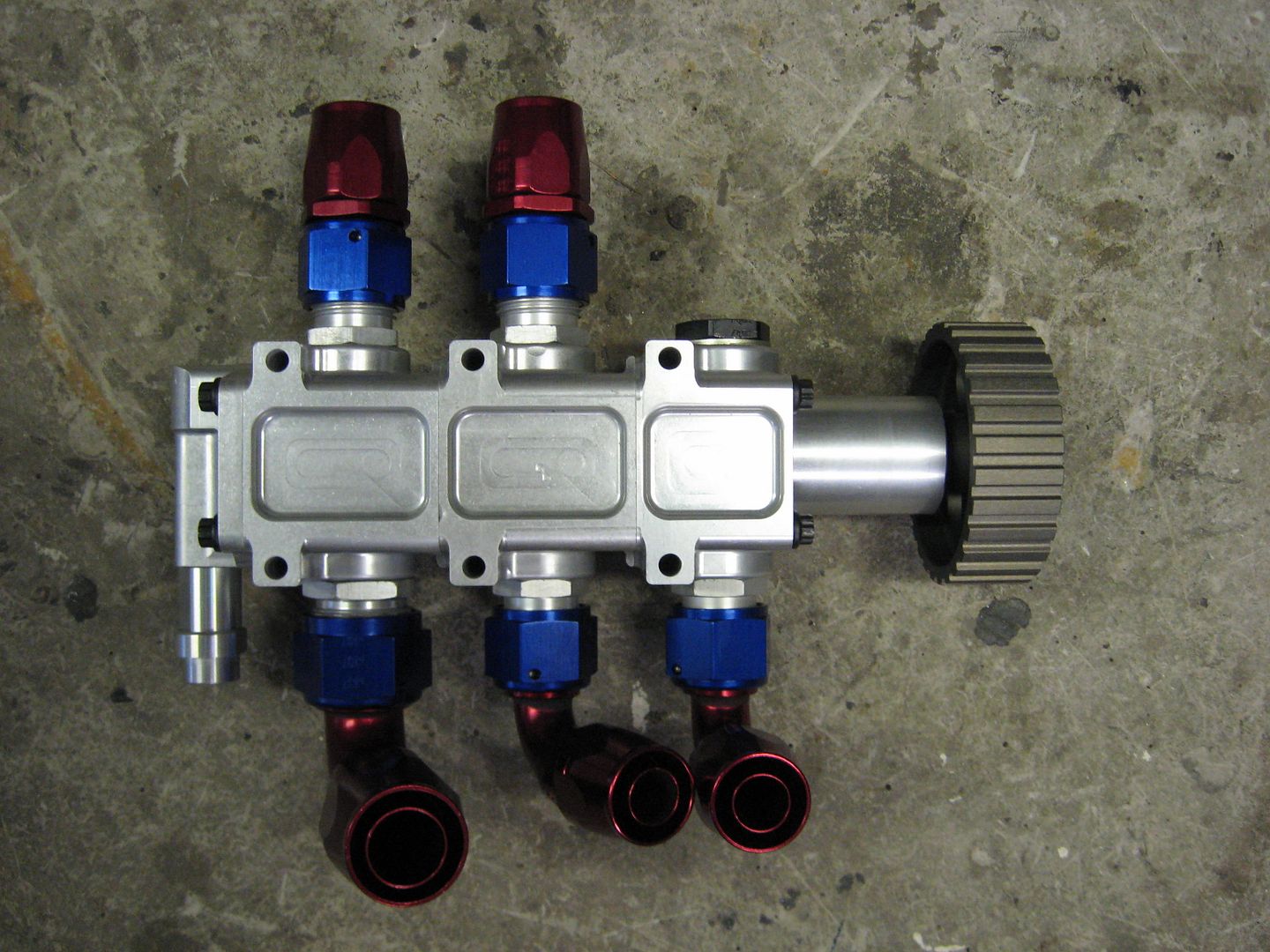

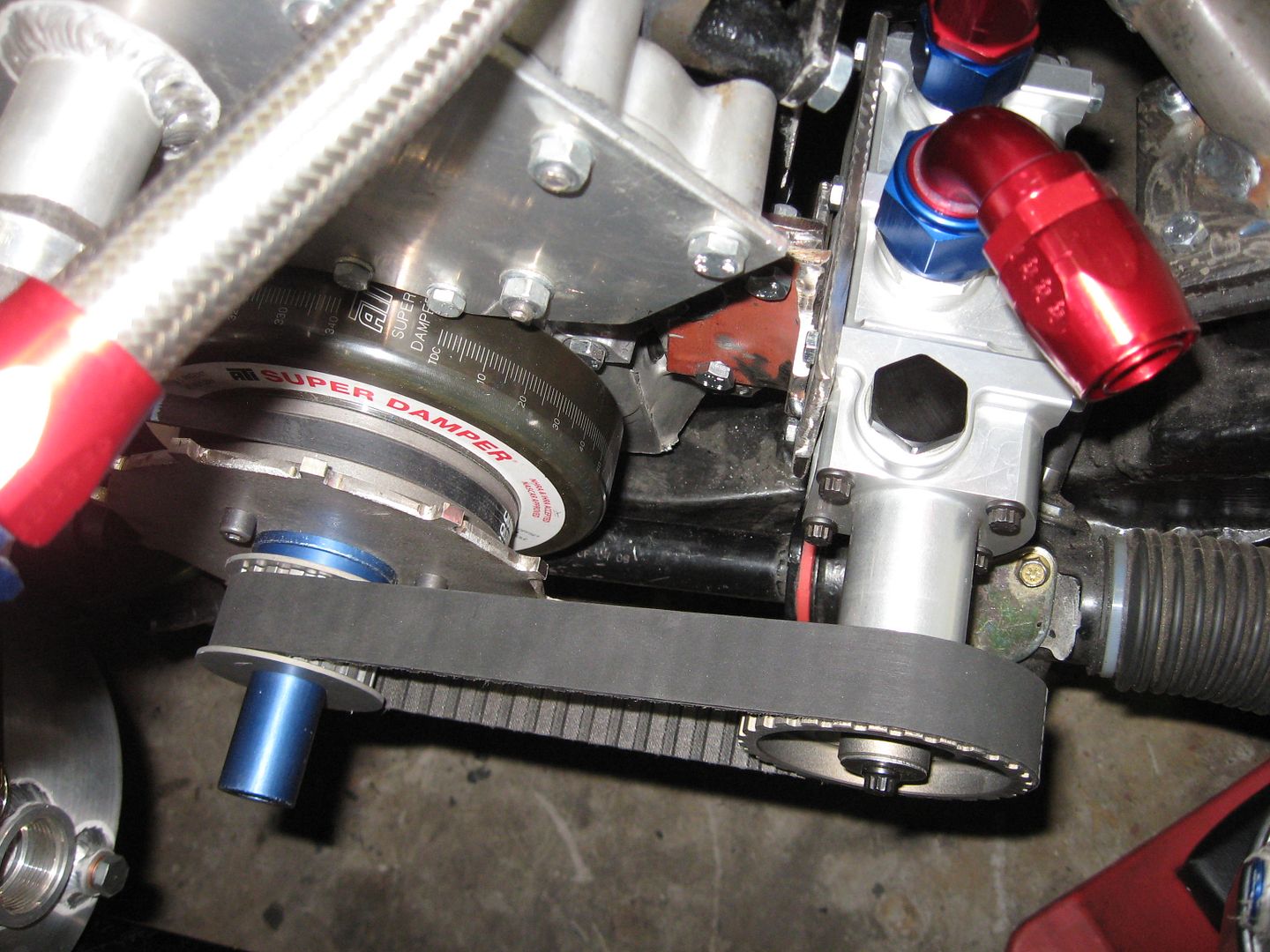

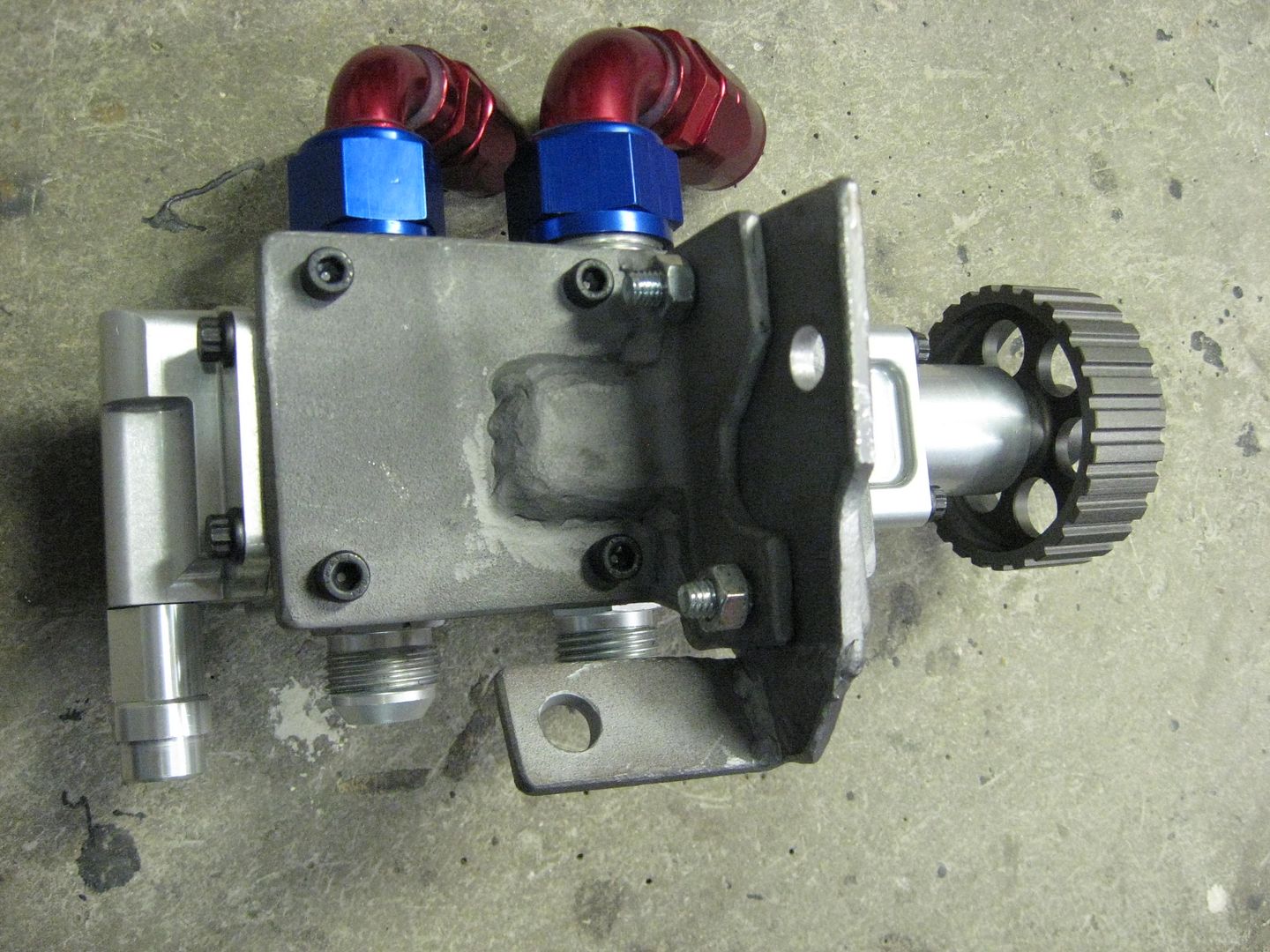

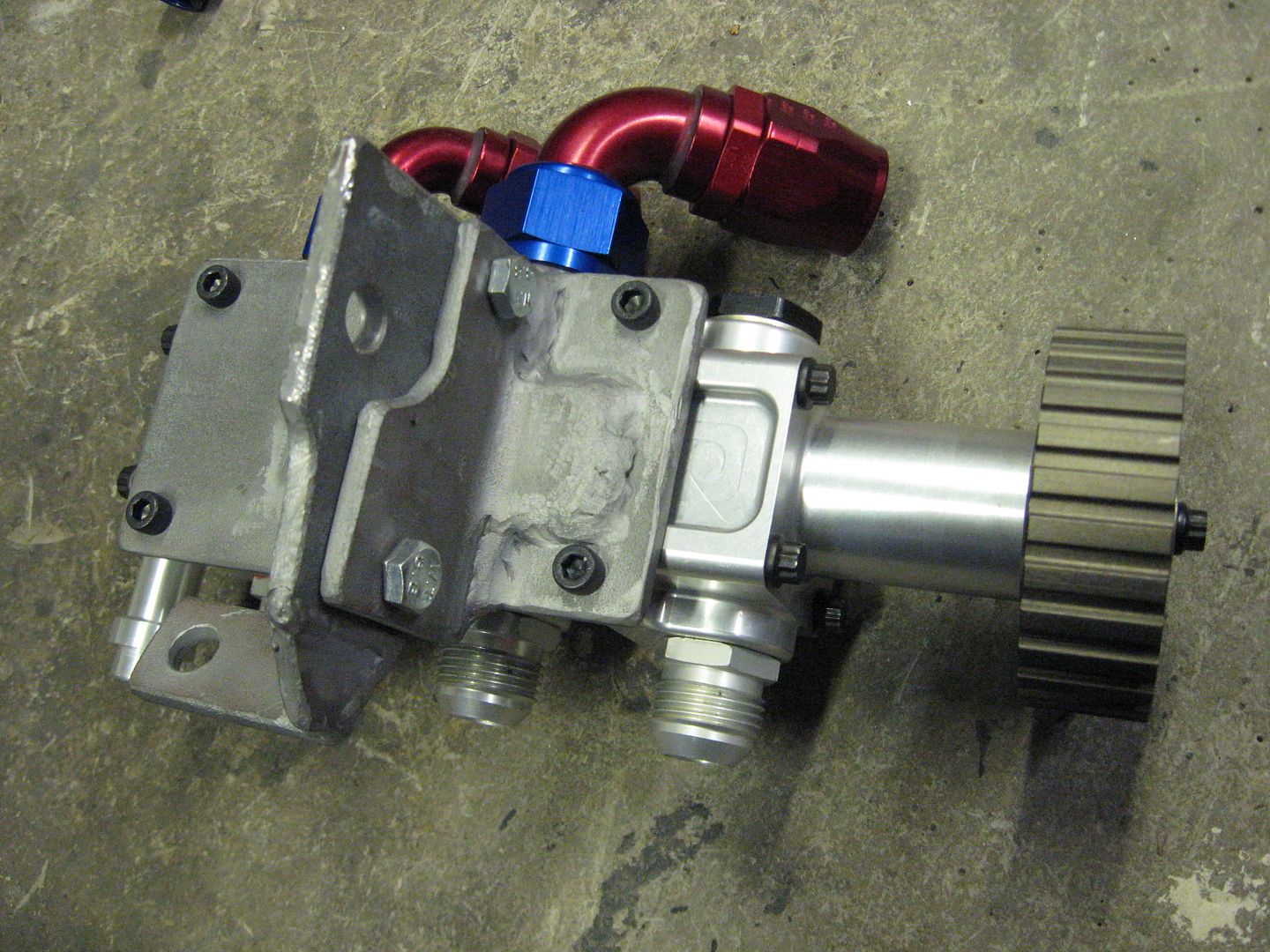

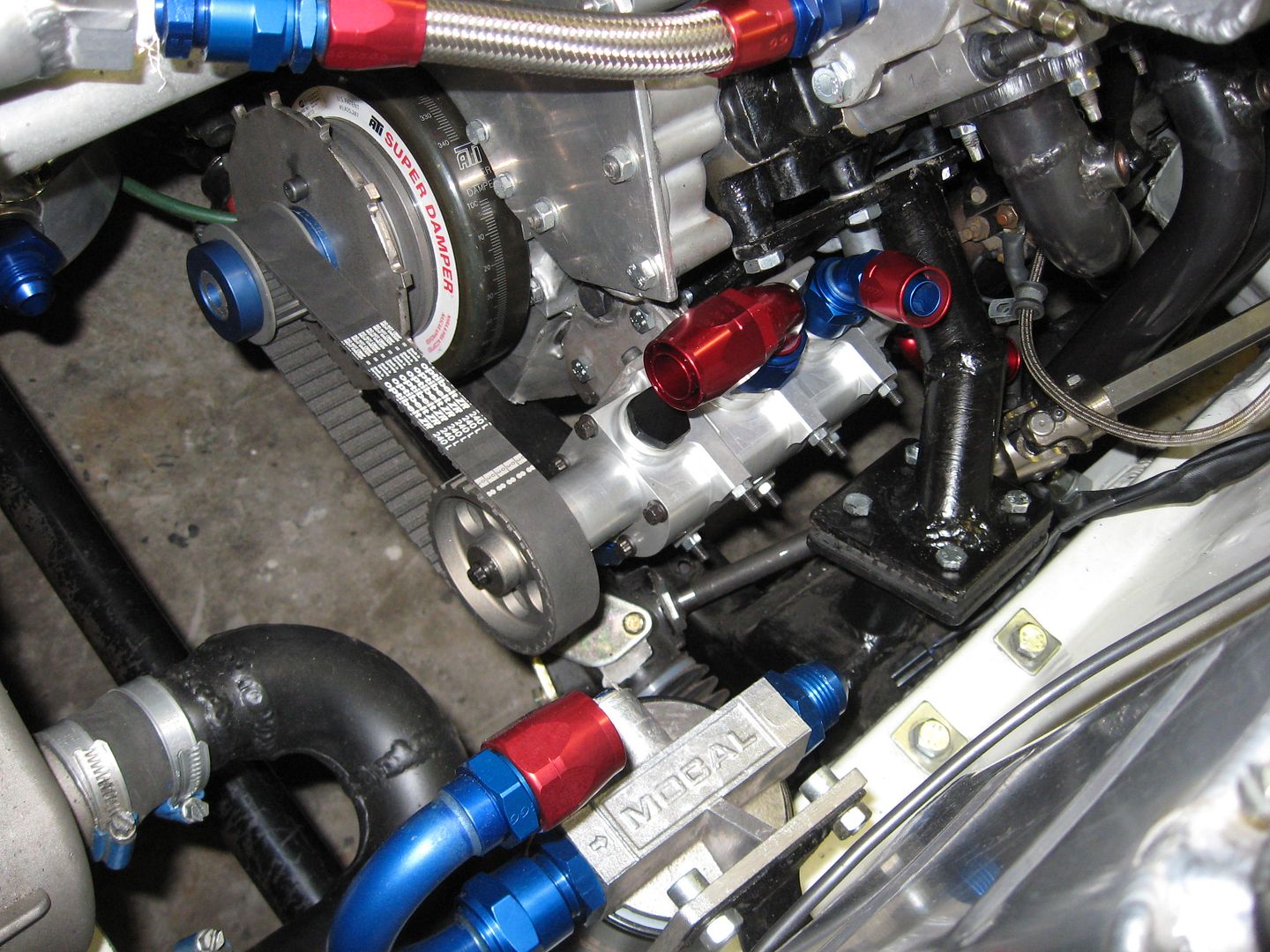

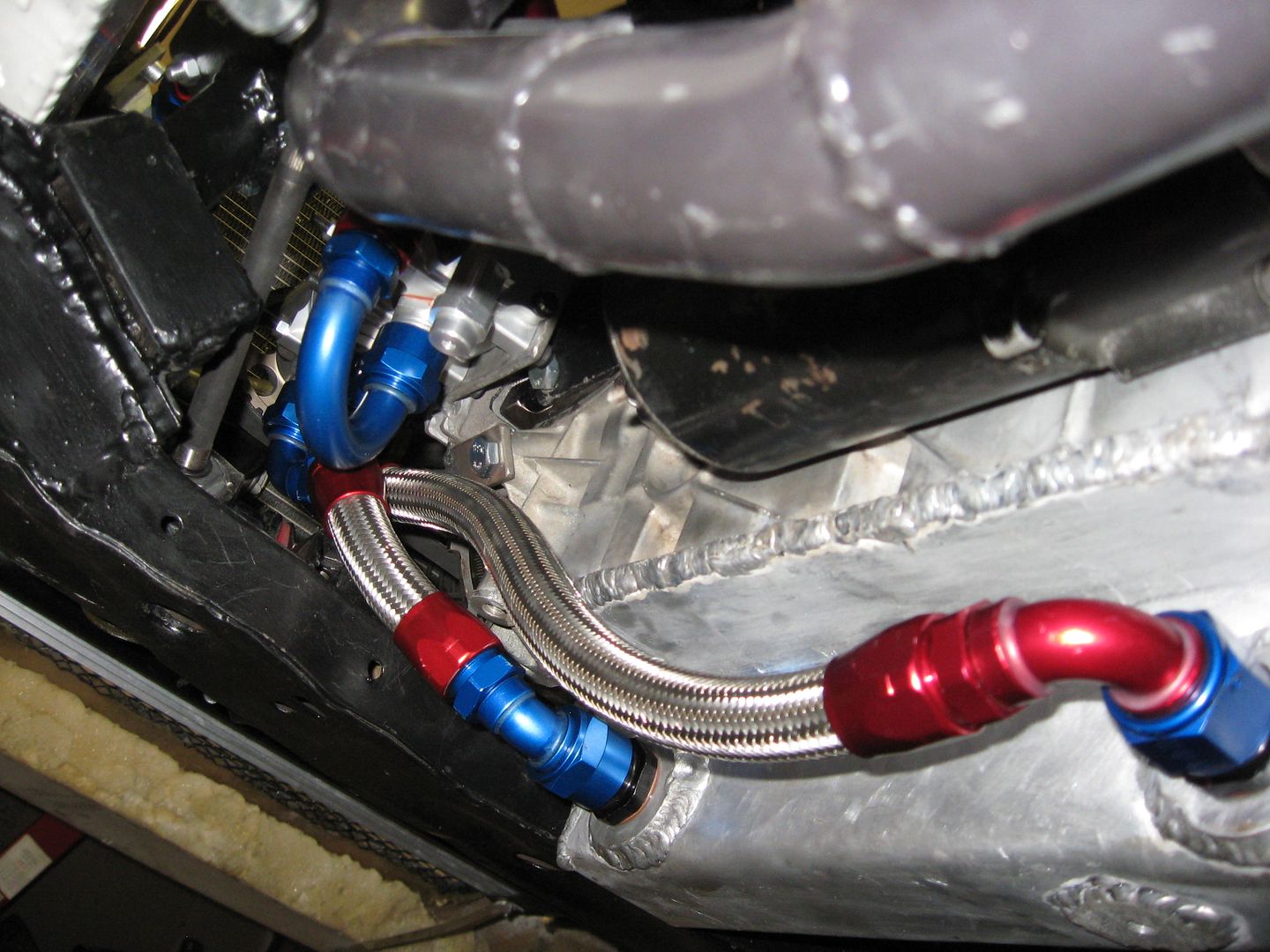

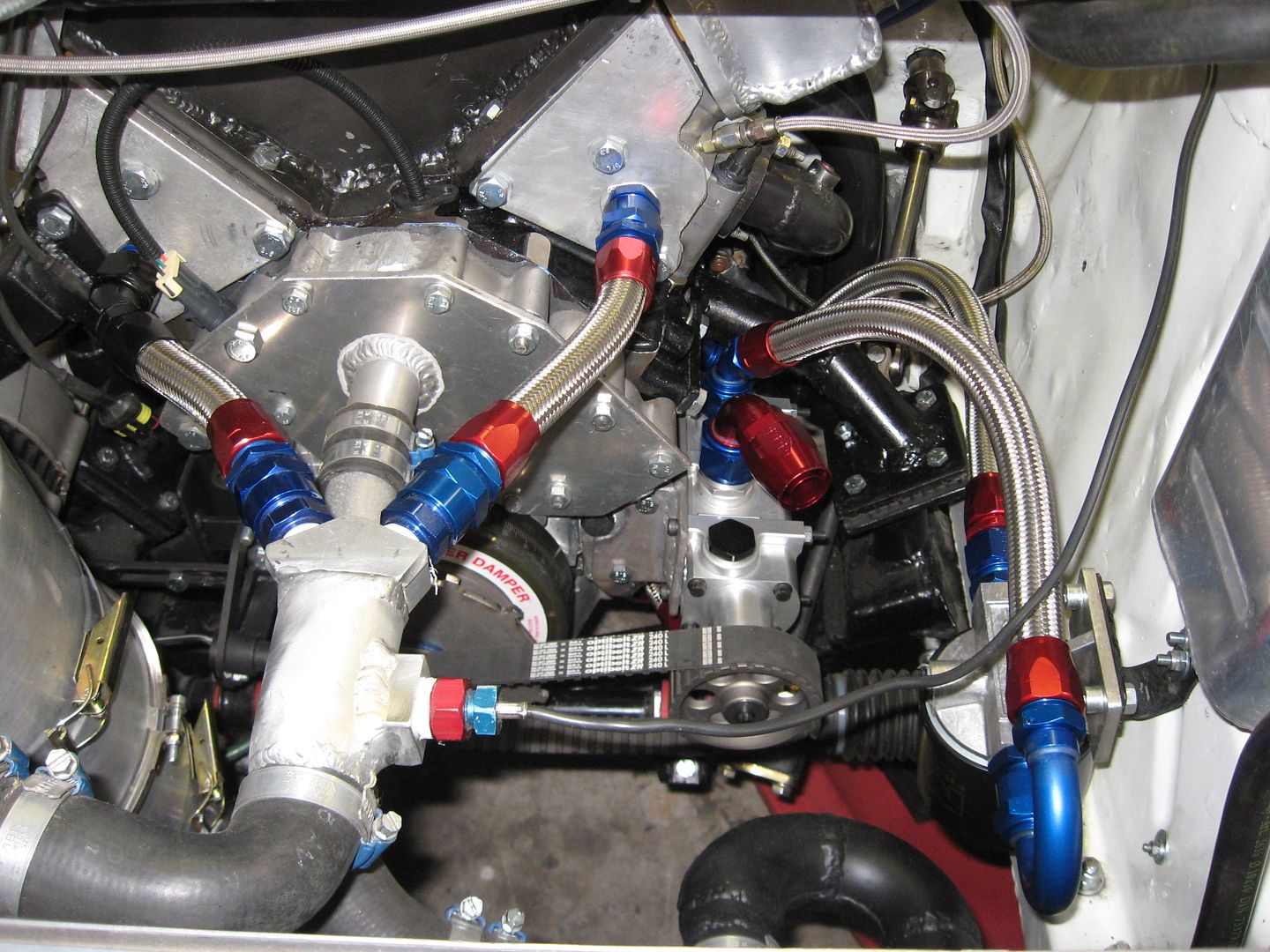

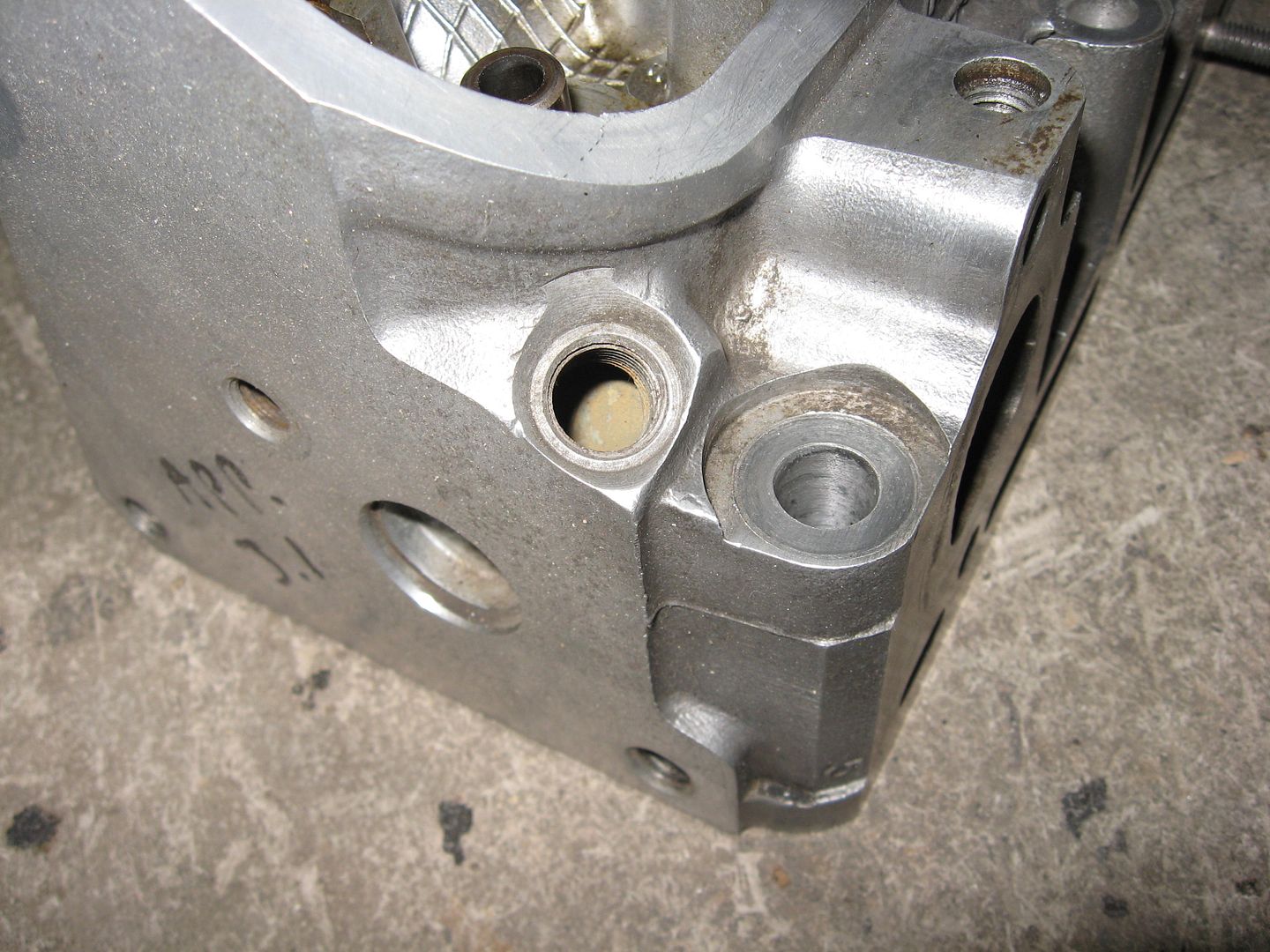

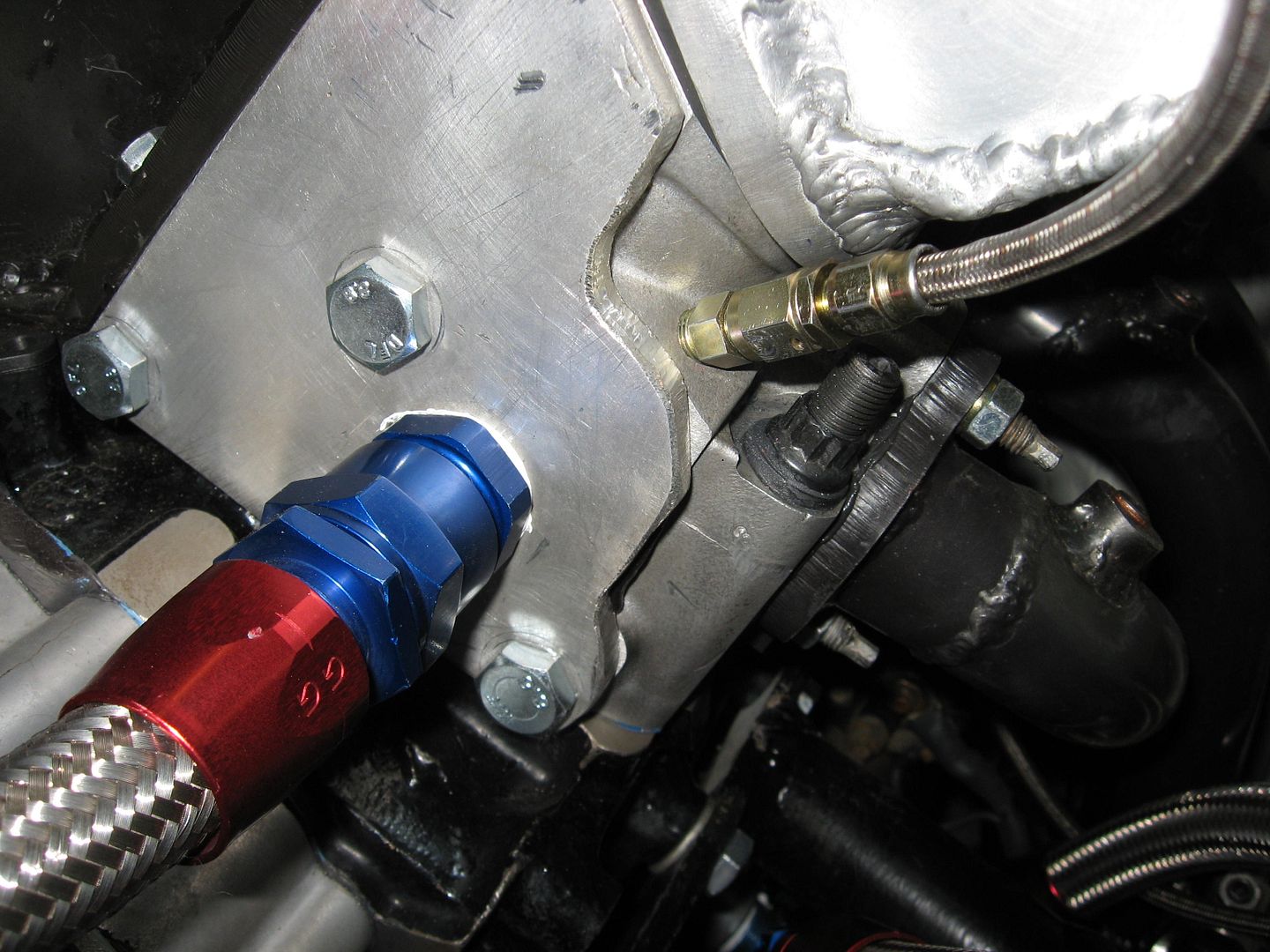

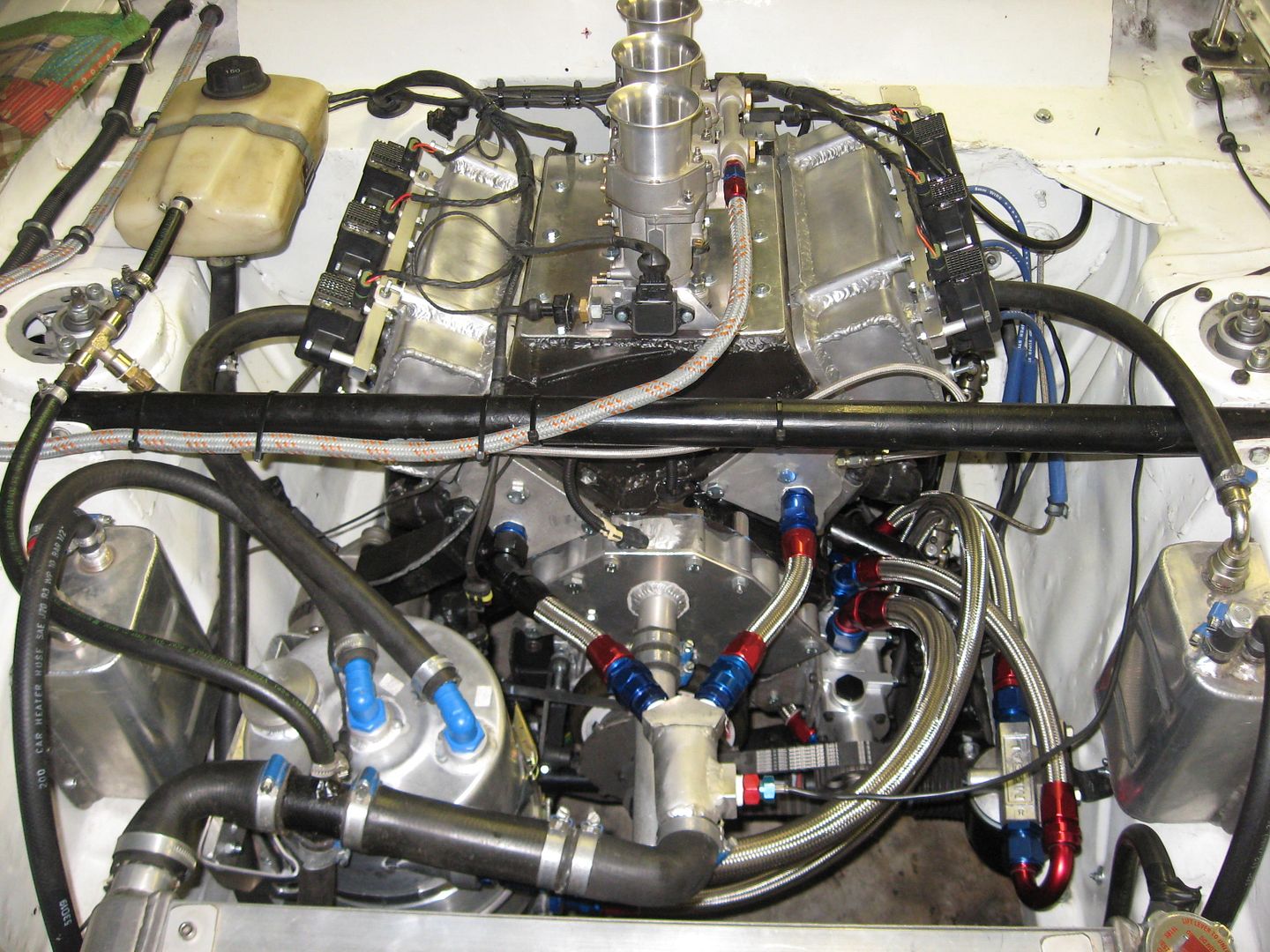

Finally got the dry sump pump the day before yesterday.

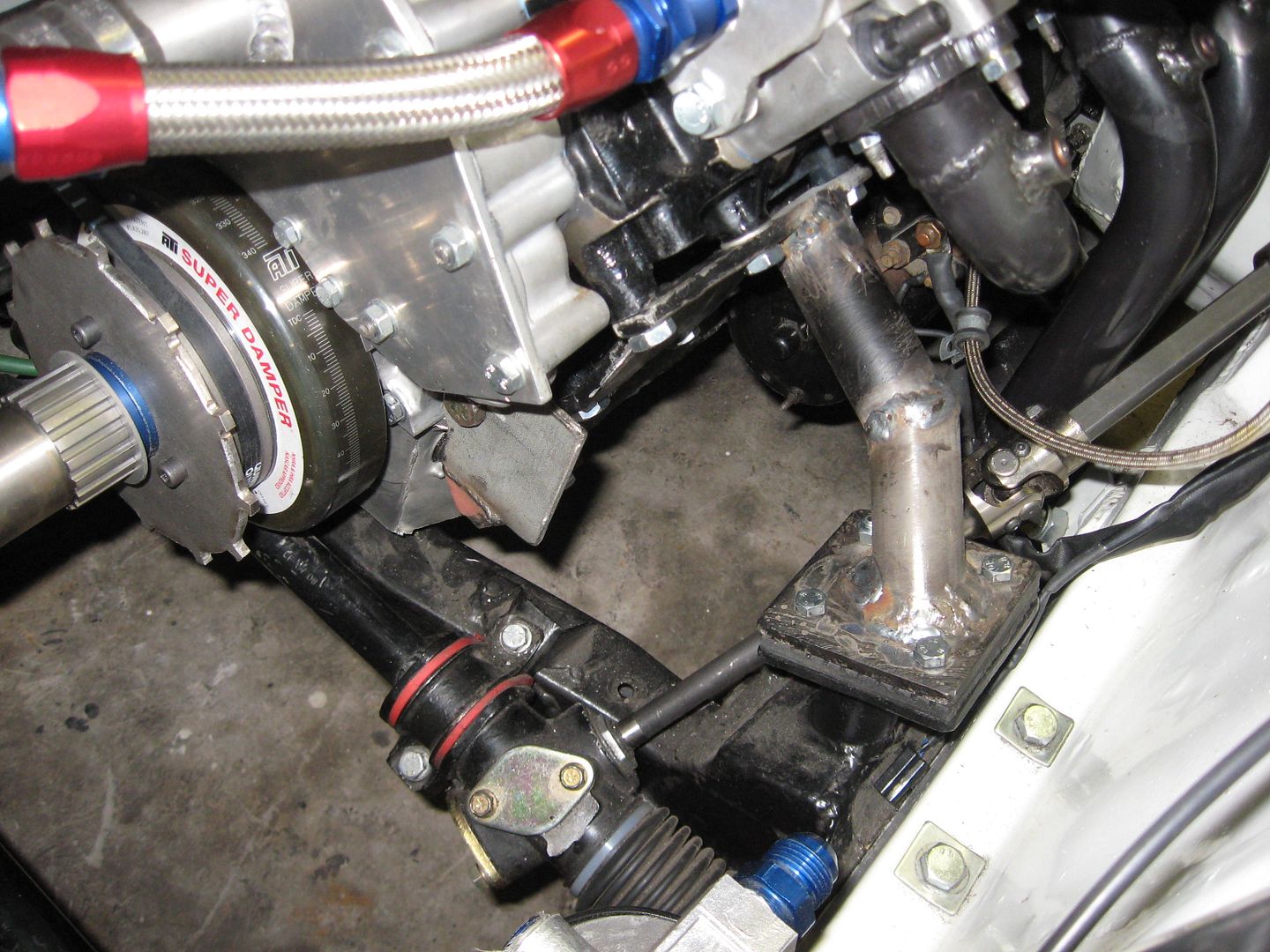

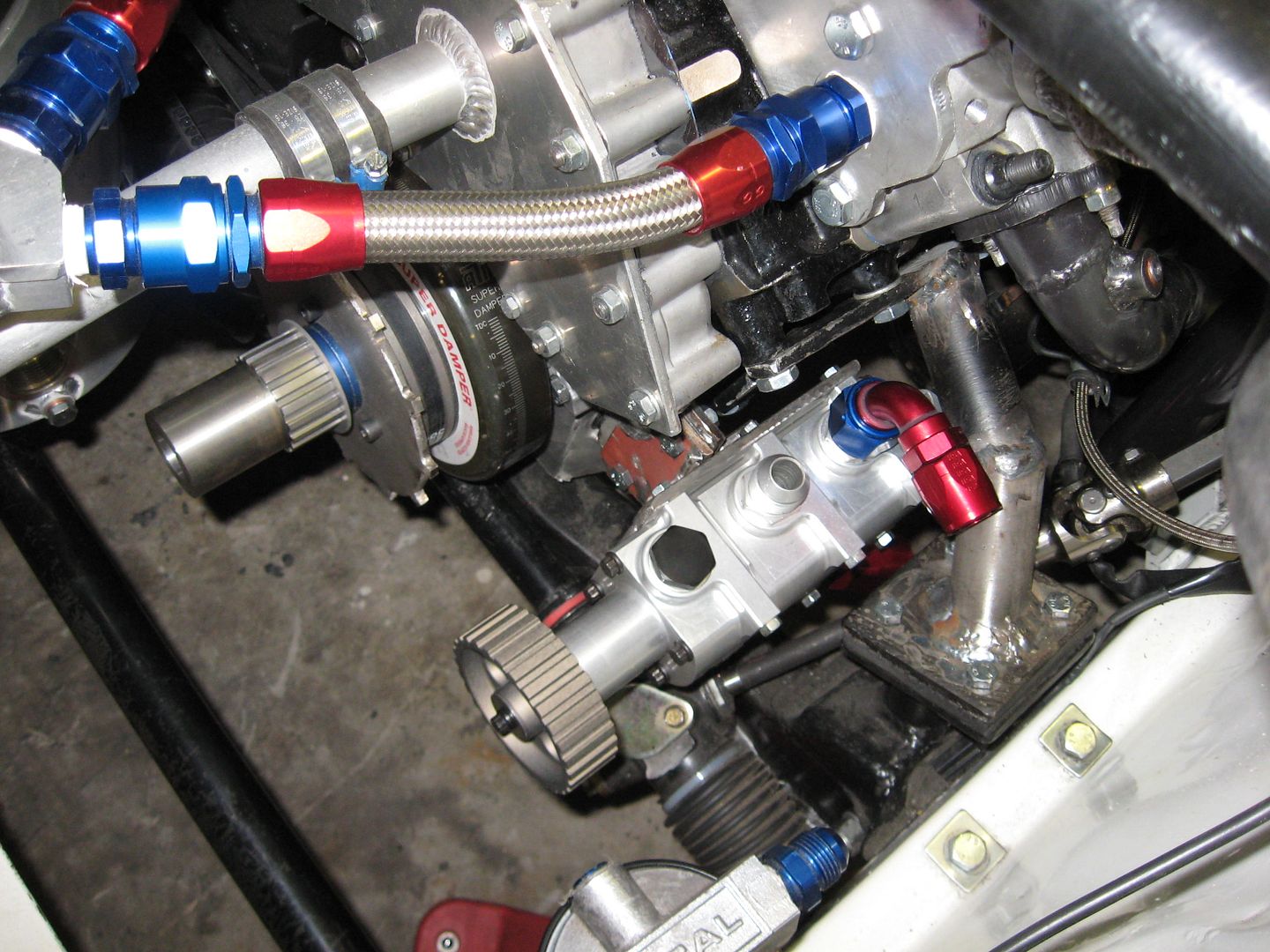

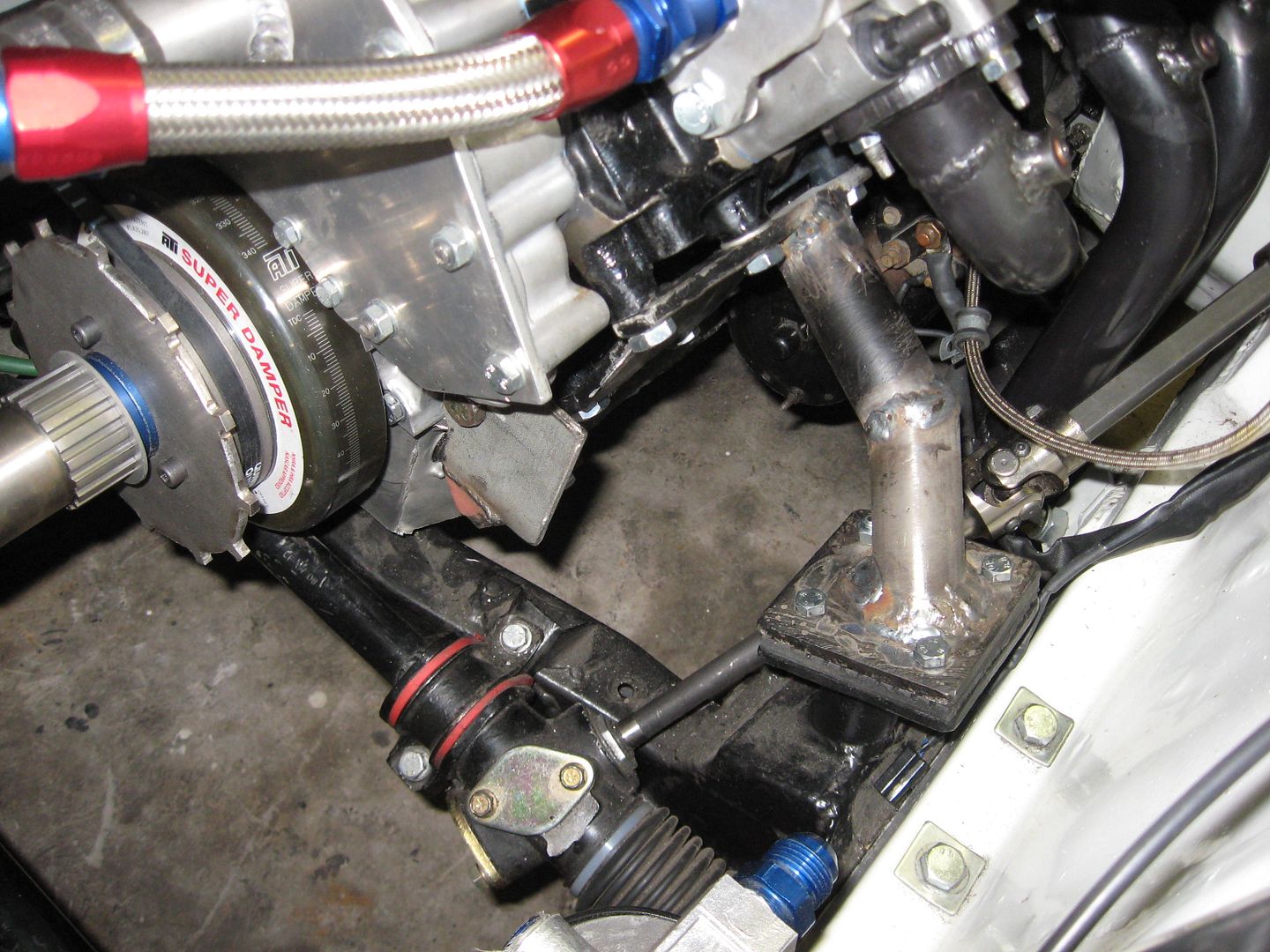

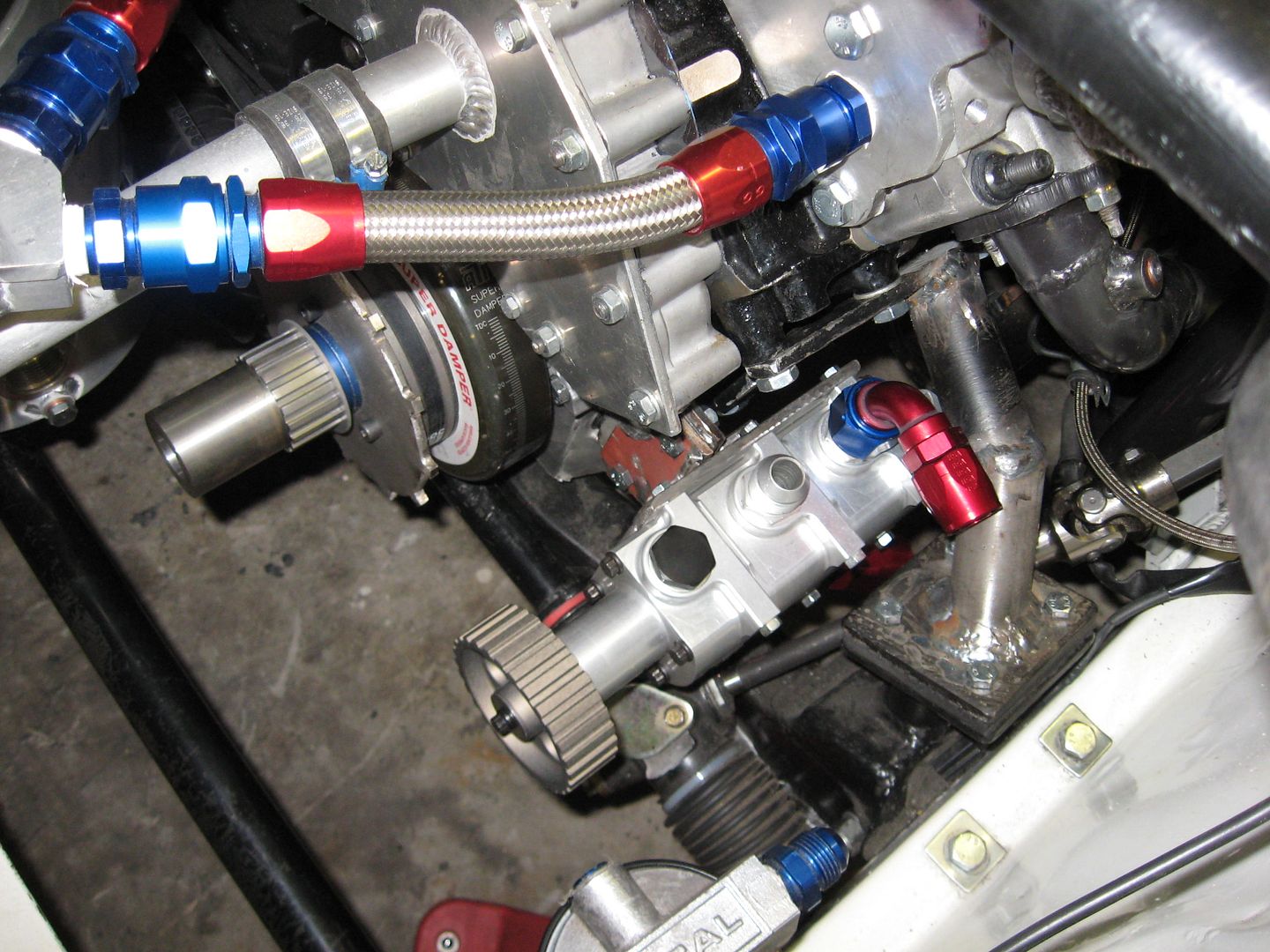

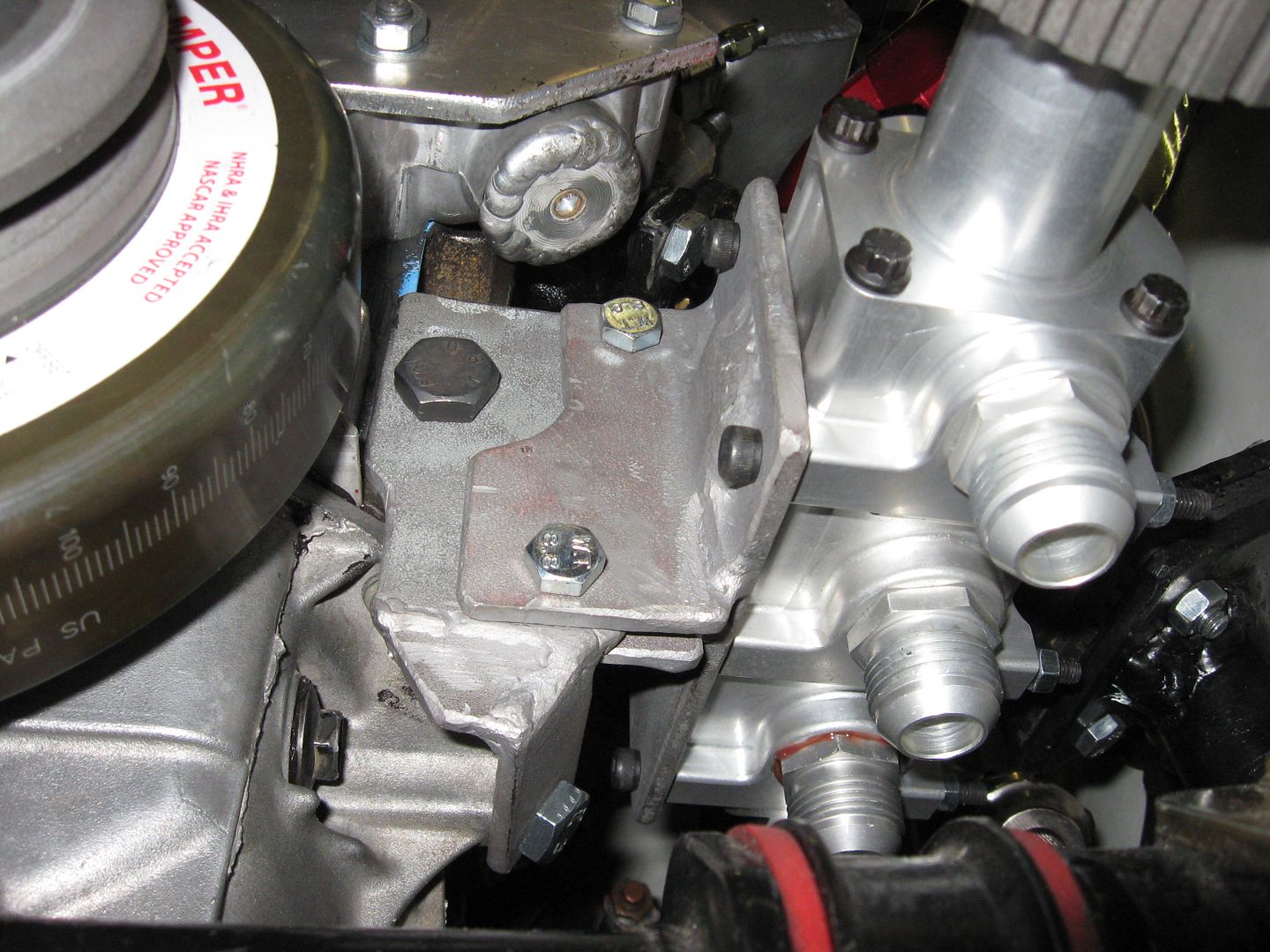

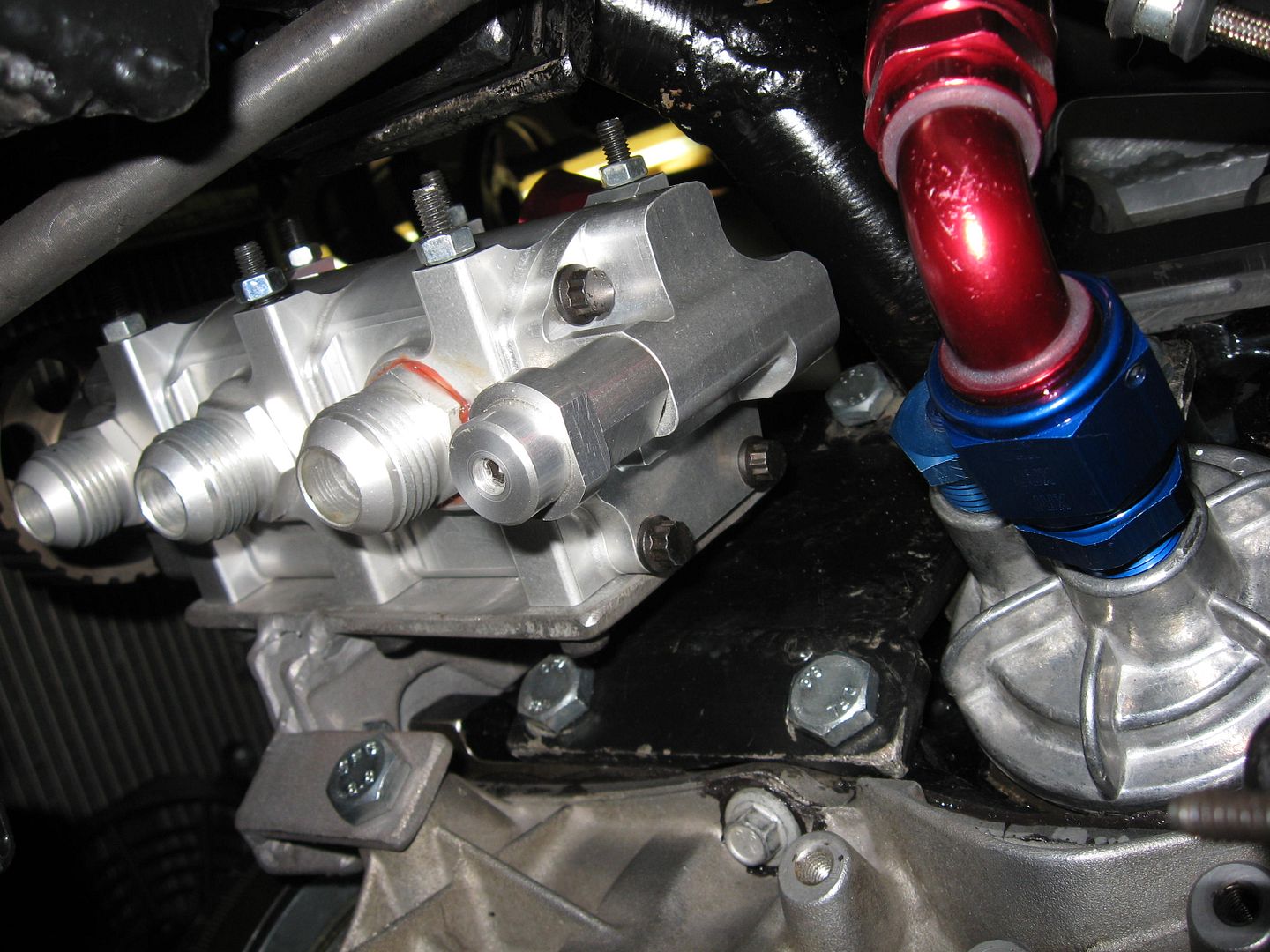

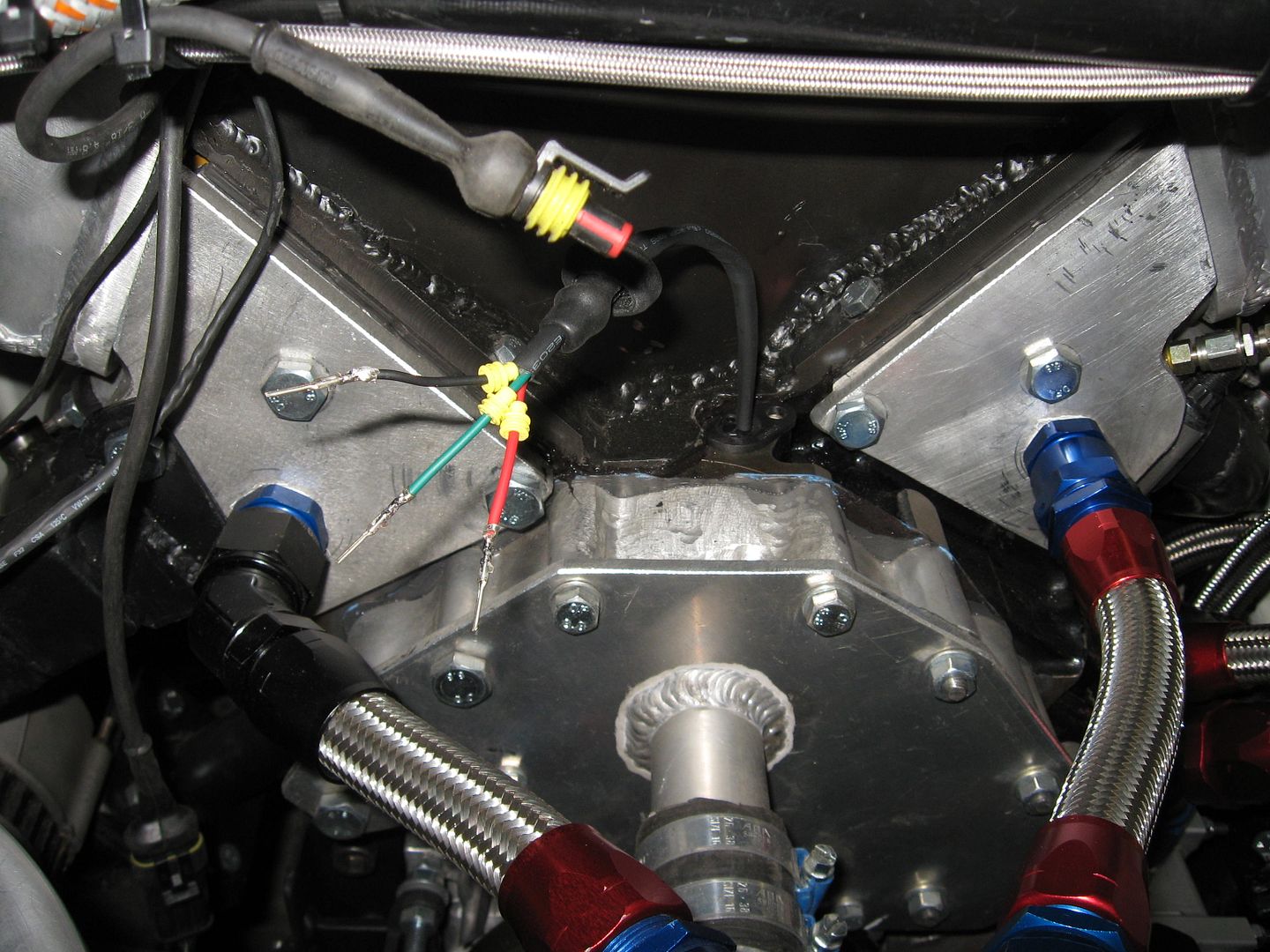

Of course it hit both the rack and engine bracket.

I did not leave enough space for it.

I had to do the engine bracket all over again.

But now it is somewhere close to the final position.

Of course it hit both the rack and engine bracket.

I did not leave enough space for it.

I had to do the engine bracket all over again.

But now it is somewhere close to the final position.

Comment