Originally posted by veekuusi

View Post

Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

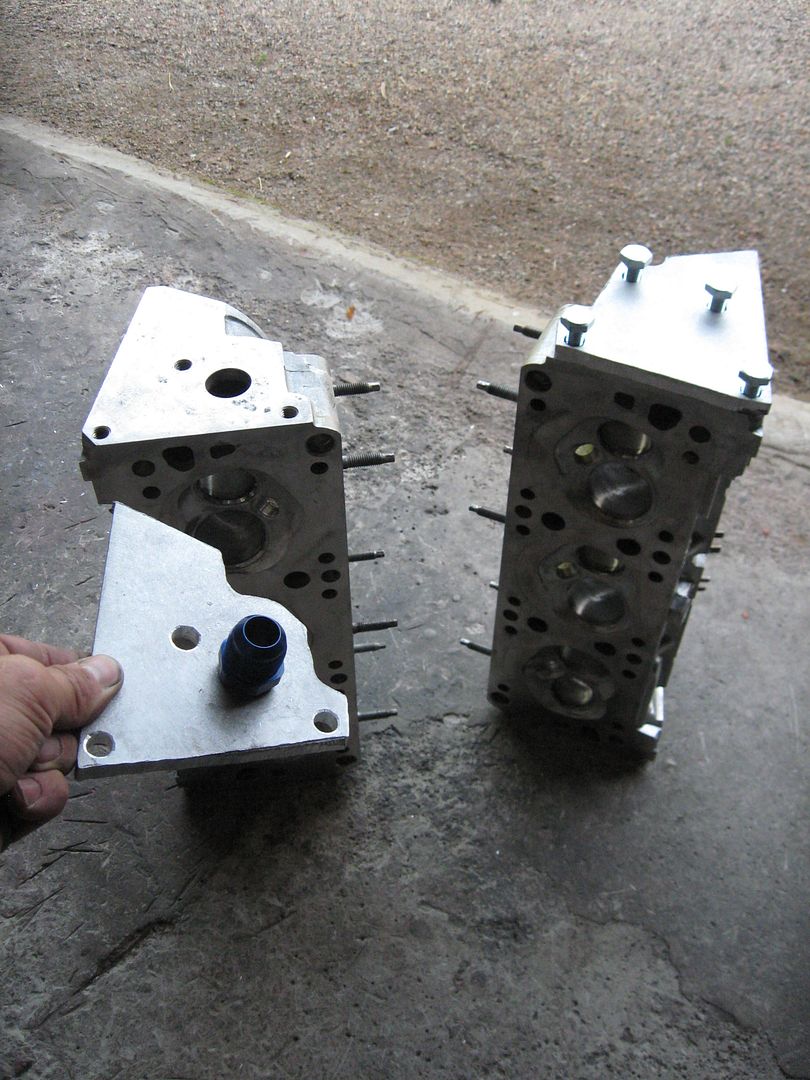

you can machine an o-ring groove around the hole, and then make a plate that catches on the accessory bolt holes on the head with an AN fitting on it where the freeze plug hole is."I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

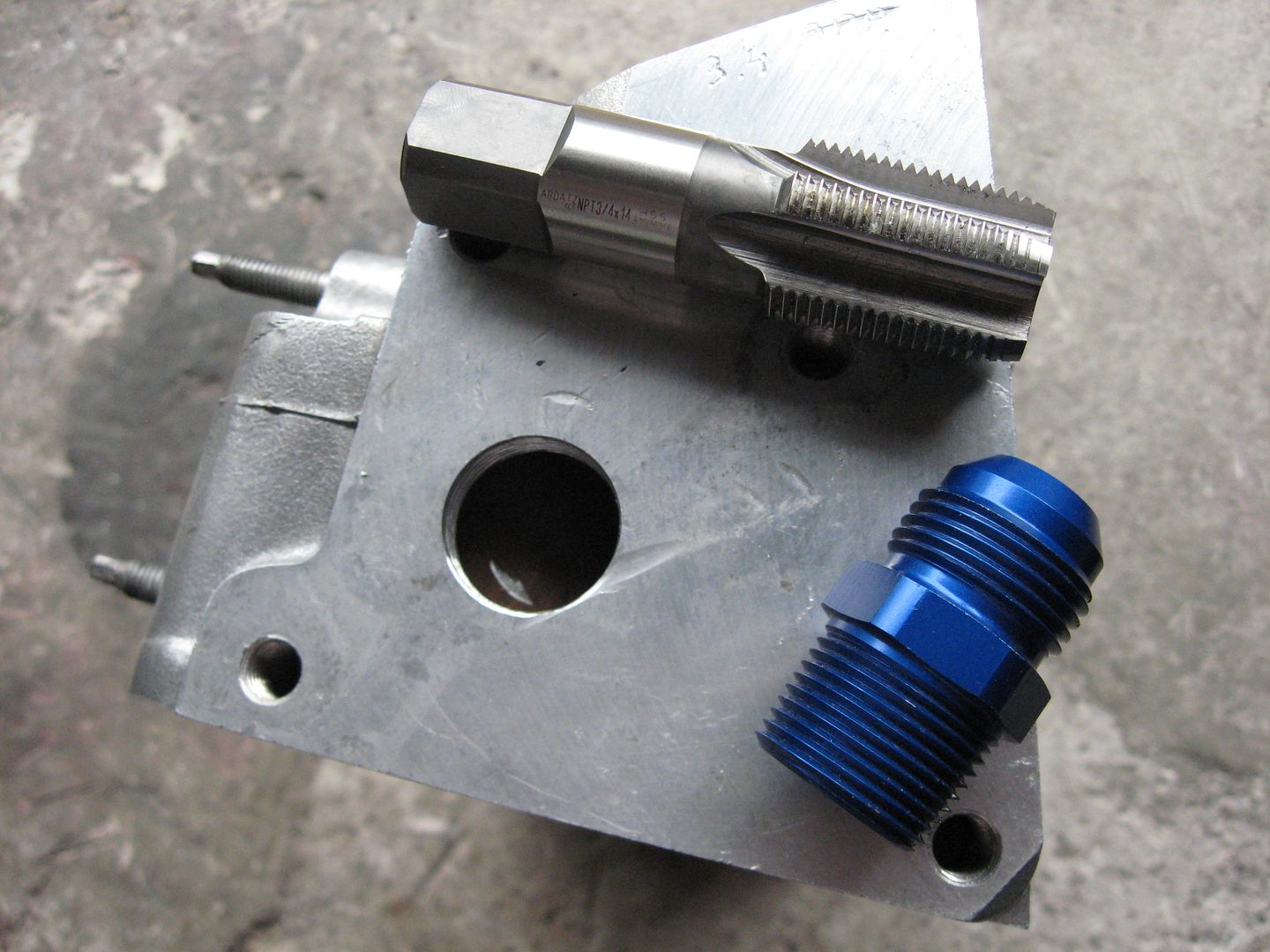

When working at a machine shop and having a tap bottom out in a hole, we would cut the tap down.Originally posted by veekuusi View PostNPT 3/4 x 14 and AN -12

Mission impossible.

You can not make the thread deep enough, the tap bottoms.

I have to weld the fitting to the head.

When you are talking about cylinder heads, best welding is no welding at all.

But what can you do?

Comment

-

I was going to suggest grind the tap shorter and if required turn the length of the fitting down.

Also make sure the oil pan is re-gusseted for lateral stiffness.

Might also want to have it re-tempered to a T6 condition. To bring the strength back up.

I'll be doing that if I decide to weld the pan like you did.

Also if you pre-heat the cylinder head to 350-400 F and use a inverter box TIG set at 120-240 HZ you should be able to weld that hole with significant damage to the head.

What engine series is this again? If I have a spare cylinder head I'll get the metallurgy checked on it to verify it is weldable (ie A356 vs a high silica 7000 series alloy).

Comment

-

Cylinder heads are from -96 Chevrolet Lumina or Transport (3400).Originally posted by NateD4 View Post.

What engine series is this again? If I have a spare cylinder head I'll get the metallurgy checked on it to verify it is weldable (ie A356 vs a high silica 7000 series alloy).

But no need for metallurgy checking, I allready made 2 flanges.

Still need to machine the grooves for O-rings.

Thanks for the advice "Ericjon 262".

Comment

-

I was going to suggest cutting the tap down as well, ive done that in the past myself

Sent from my iPhone using my iPhone at work cuz I have nothing to do

Comment

-

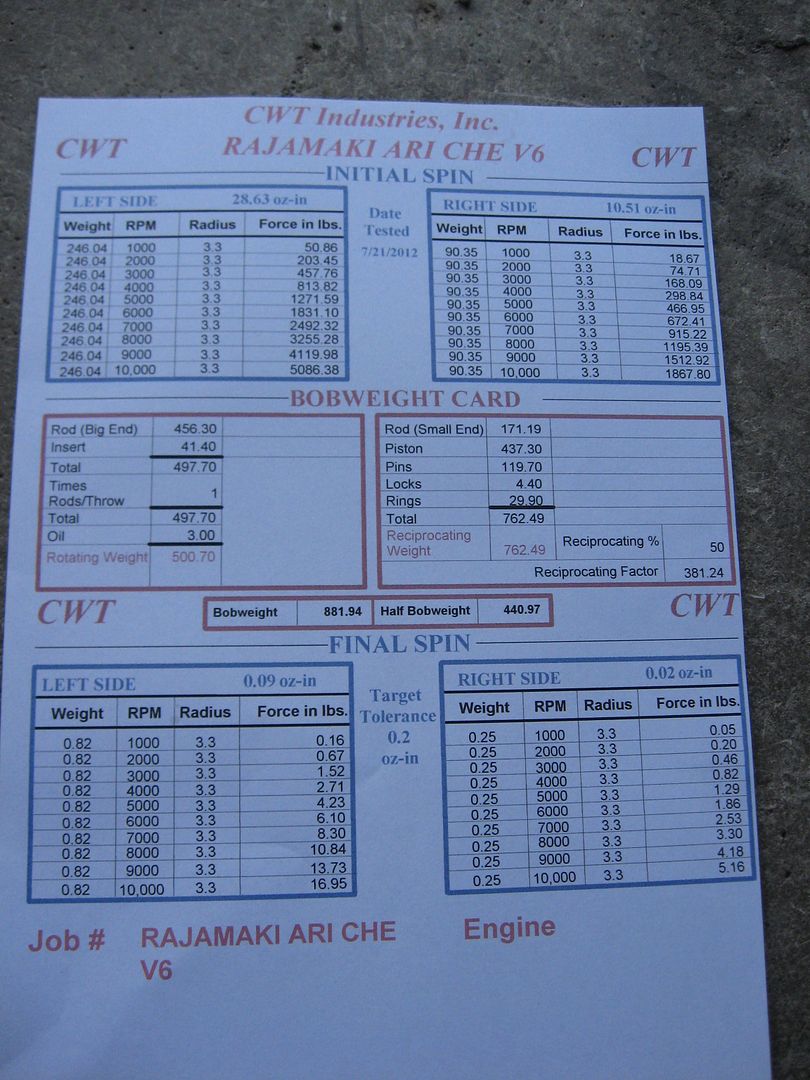

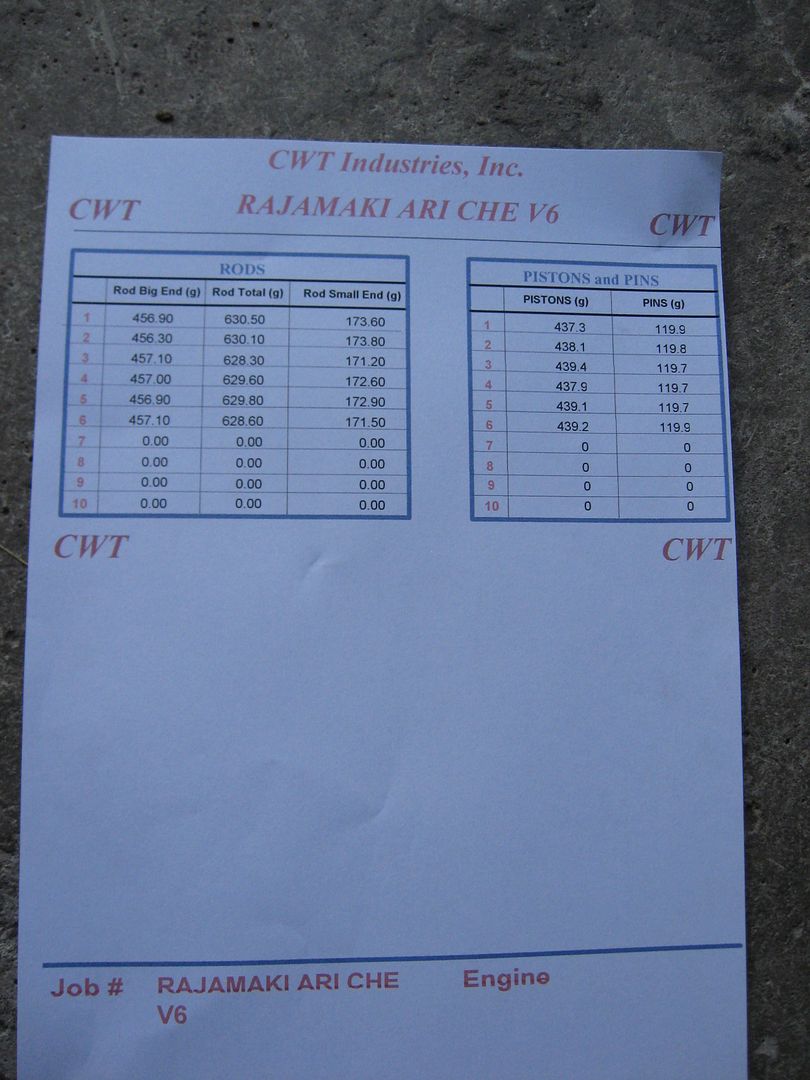

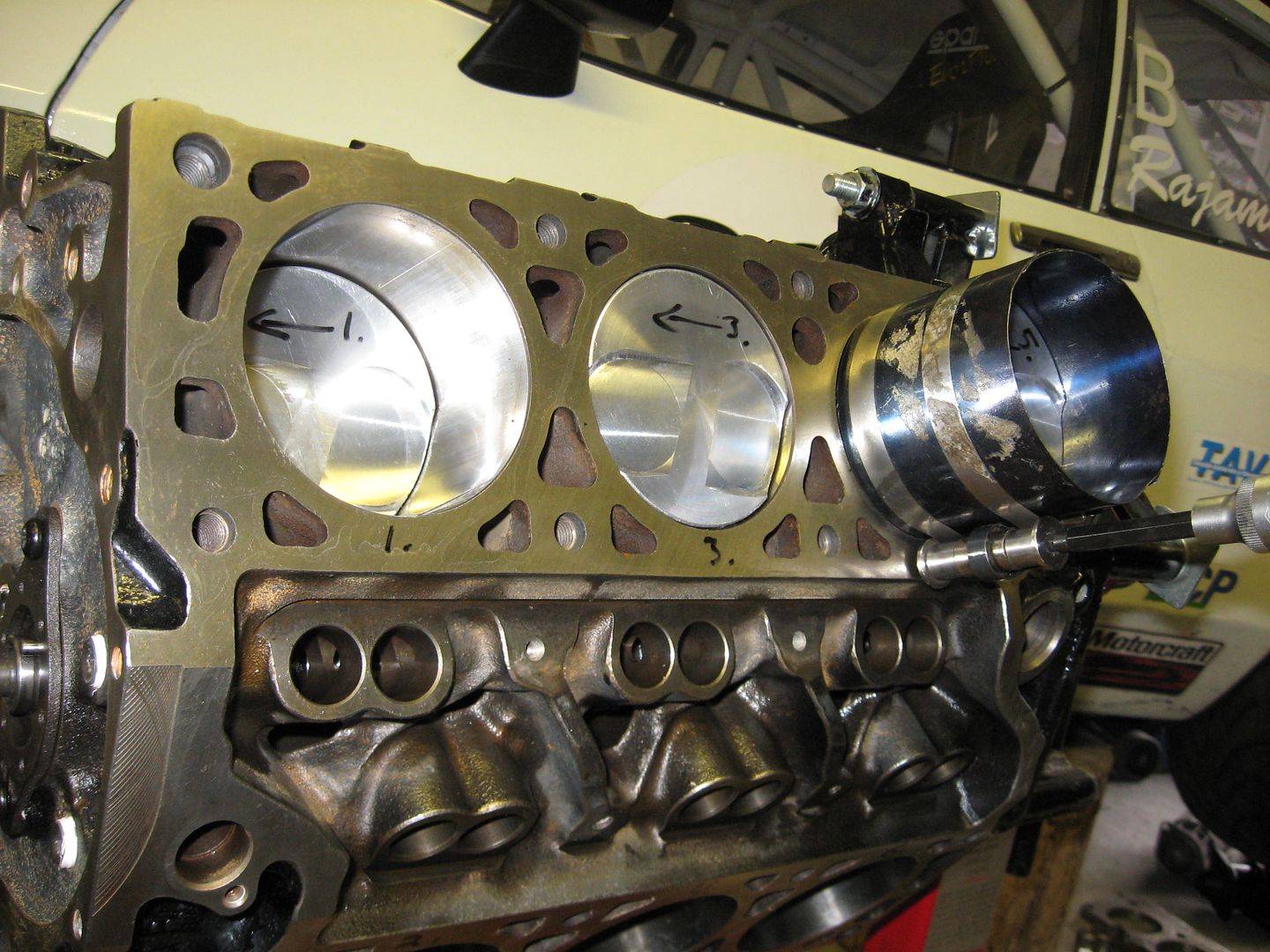

Just got the bottom end back from balancing today.

It was the "second most difficult balancing job" for the machine shop.

Forgot to ask , what was the most difficult.

Five "mallorys" had to be added to the crankshaft.And they did not have enough them,

we had to wait the shipment from USA.

They managed to do it to inner balance.

Although the crankshaft was ment to be outer balanced.

Comment

-

That is a aftermarket crank .

Mains are 67.25 mm (bigger ones).

Manufactured by Eagle (In China, where else).

It is said to take 300 horses which is by the way my goal with this engine.

This crank is maybe the weakest point in my engine.

We will see how much rpm it can take.

And one has to be quite blind , if he does not see the huge play

in the main caps when installing a small bearing crank to a 1996 year block.

At least that engine would not run very far.Last edited by veekuusi; 07-24-2012, 07:51 AM.

Comment

-

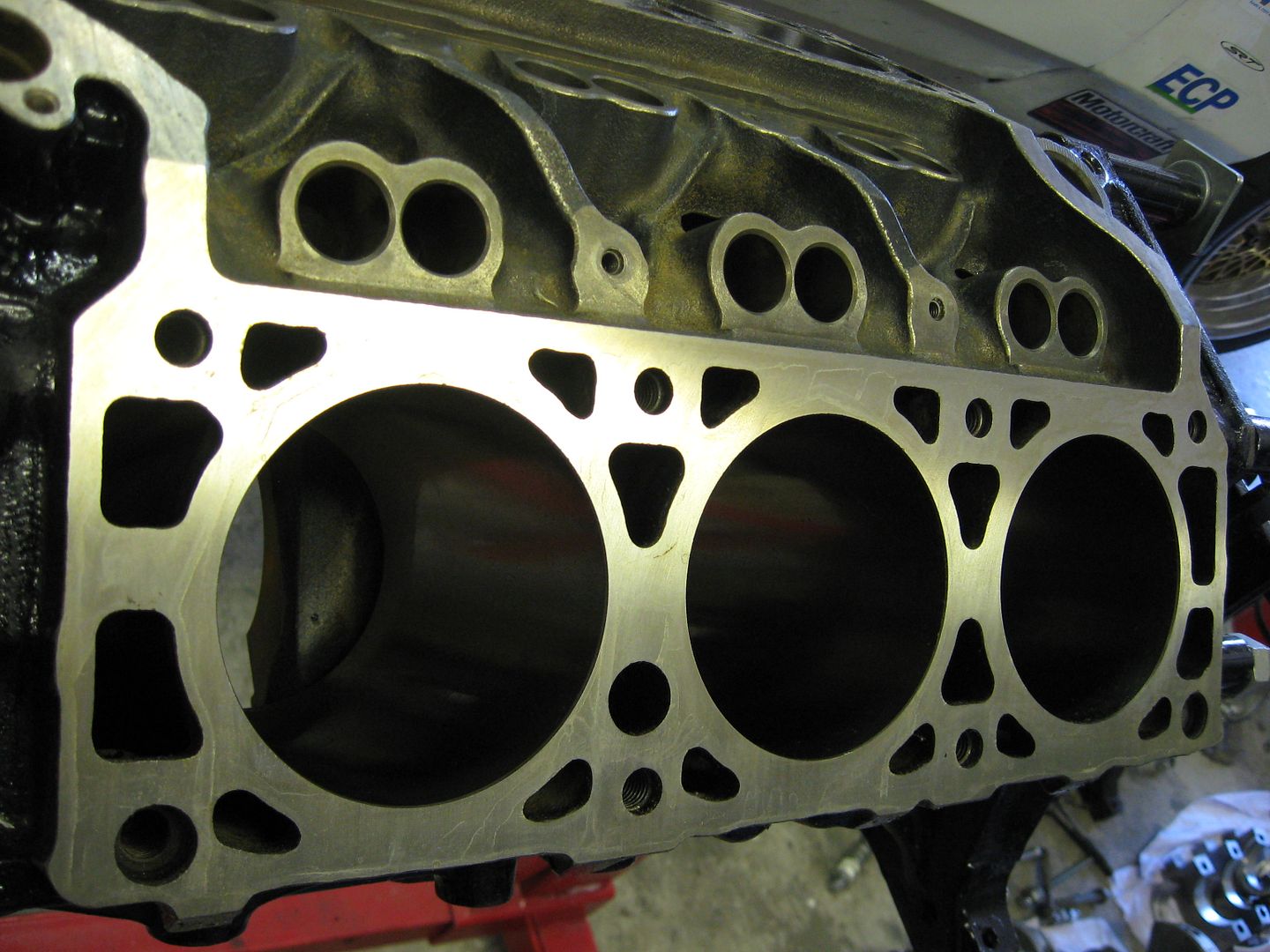

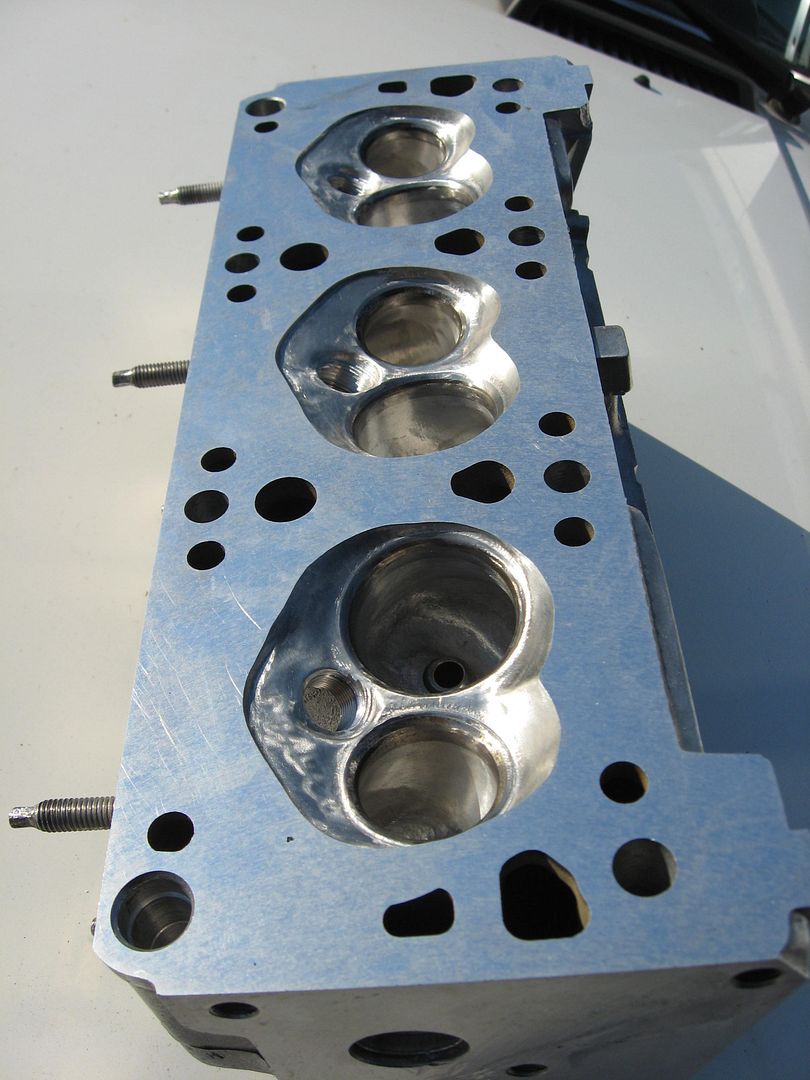

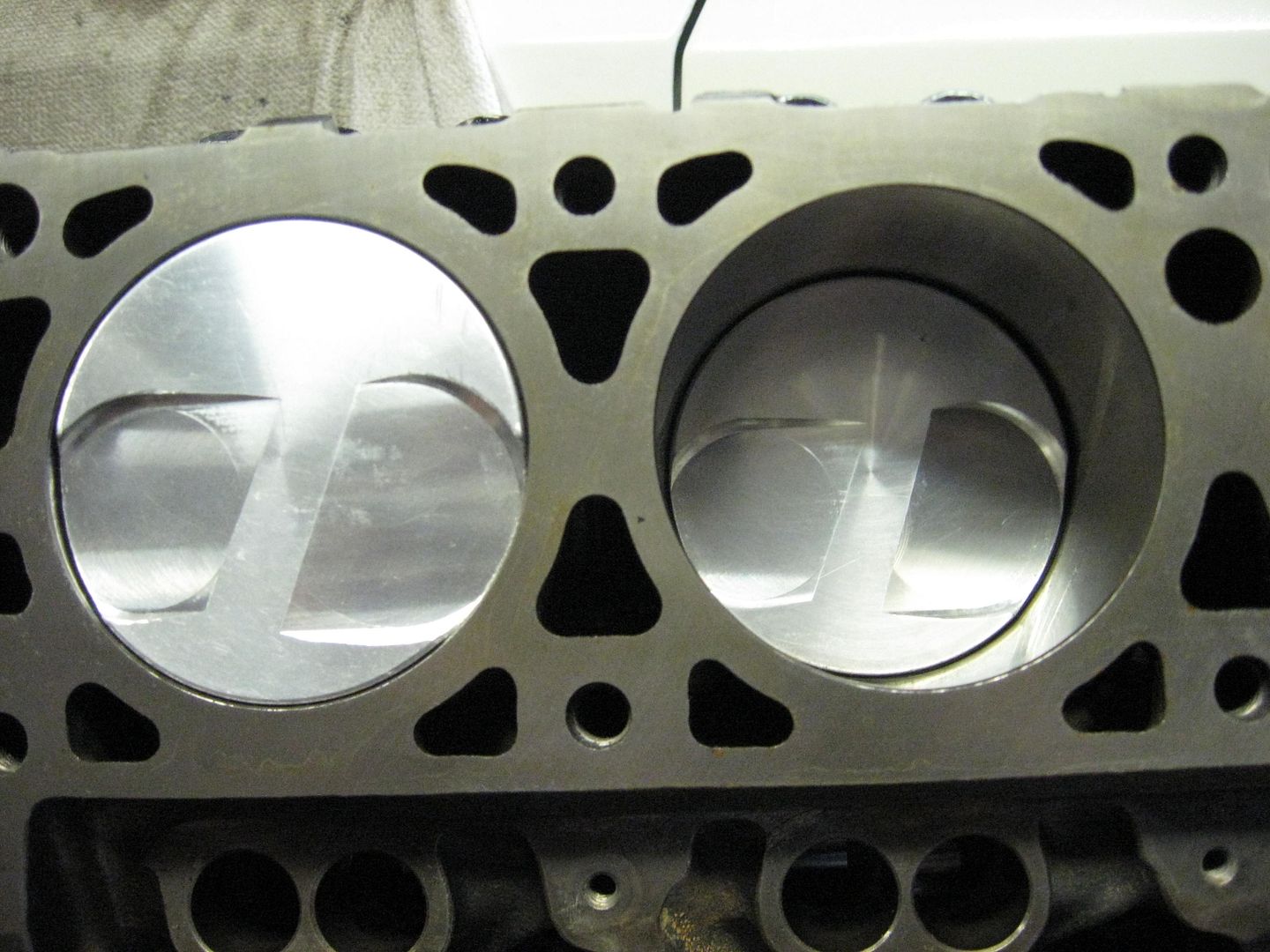

And finally, the engine assembly can begin.

Just got the block from the shop.

I wanted to mill the block deck surface , so there is no issue with the Cometic head gaskets.

50RA or finer says in the Cometic installation sheet.

"It becomes what it becomes, it is done with a stone".

Said the man in the machine shop, when I asked is he familiar with this installation tip.

He was having a bad day, but the outcome seems to be okay.

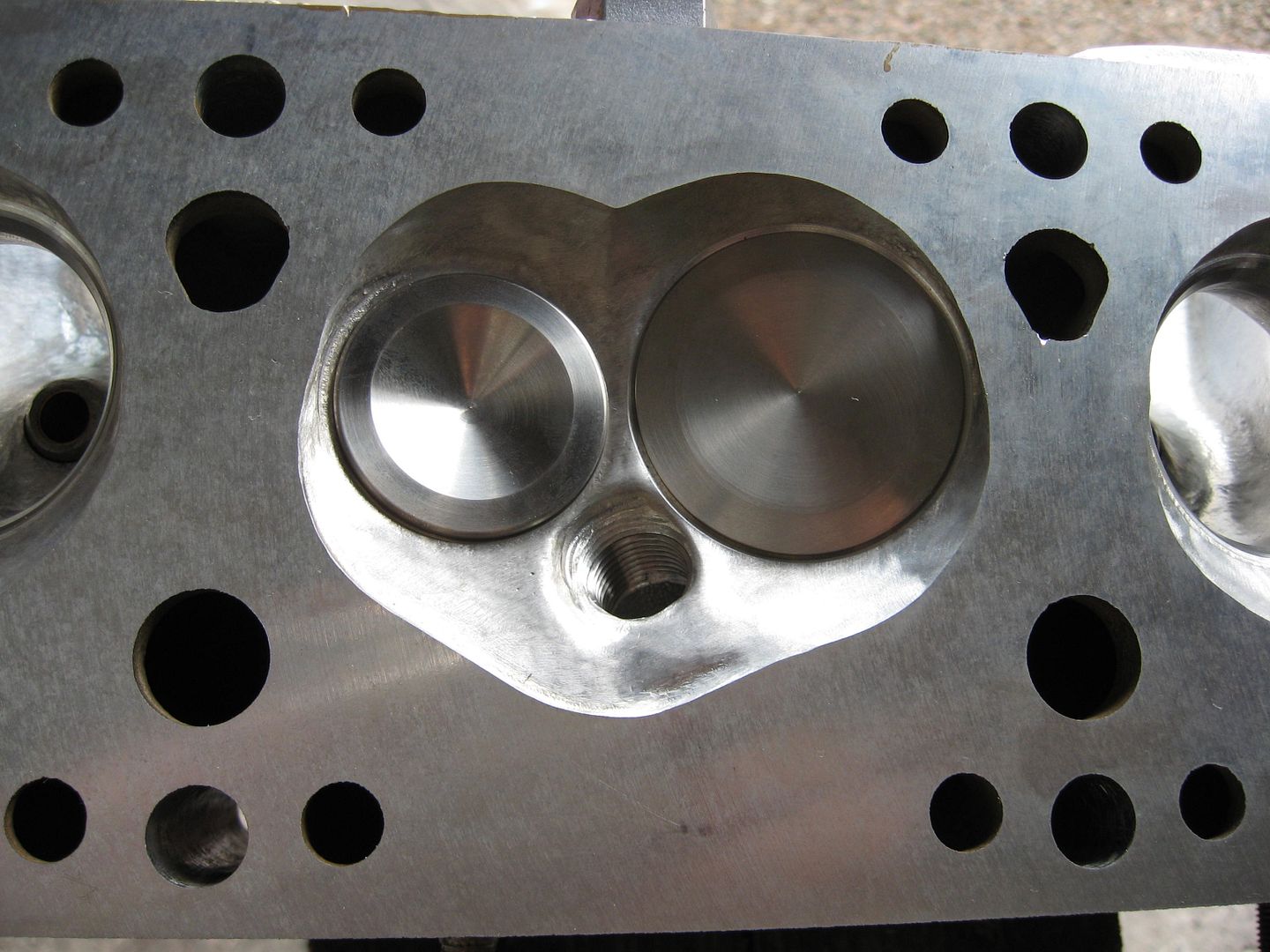

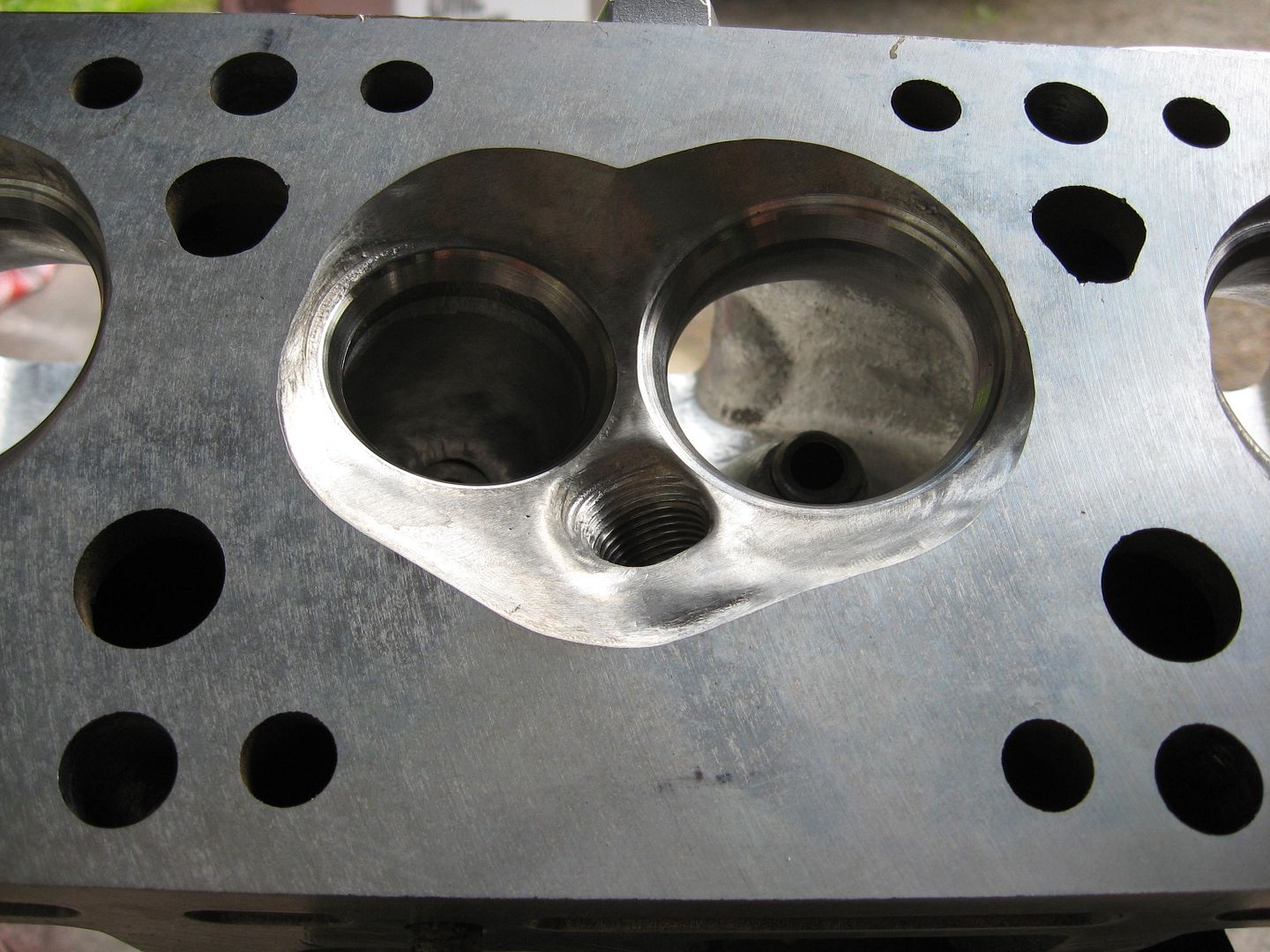

And also the heads were milled, they look quite smooth.

Just to get the scratches away.

K-line bronze valve guide liners were installed.

KL 1851 C , they have some kind of teflon coating.

"Big boys" adviced me to use them.

Last edited by veekuusi; 07-28-2012, 01:10 PM.

Last edited by veekuusi; 07-28-2012, 01:10 PM.

Comment

-

Looking nice, man.

Sent from my HTC One X using Tapatalk 2-60v6's 2nd Jon M.

91 Black Lumina Z34-5 speed

92 Black Lumina Z34 5 speed (getting there, slowly... follow the progress here)

94 Red Ford Ranger 2WD-5 speed

Originally posted by Jay LenoTires are cheap clutches...

Comment

-

Everything is metric!

Got Lope?

3500 Build, Comp XFI Cam 218/230 .050 dur .570/.568 lift 113LSA

Fully Balanced, Ported, 3 Angle Valve Job, 65mm TCE TB, S&S Headers.

Stage-1 Raybestos/Alto 4t60e-HD, EP LSD, 3.69FDR

12.61@105 Epping NH Oct 2015 Nitrous 100shot (melted plugs) 13.58@98.8 N/A 3200LBS

Comment

-

I did some rough conversions, looks like .5 lift on the intake side was around 204 cfm. if i get time later on i may try to convert all of it.

Comment

-

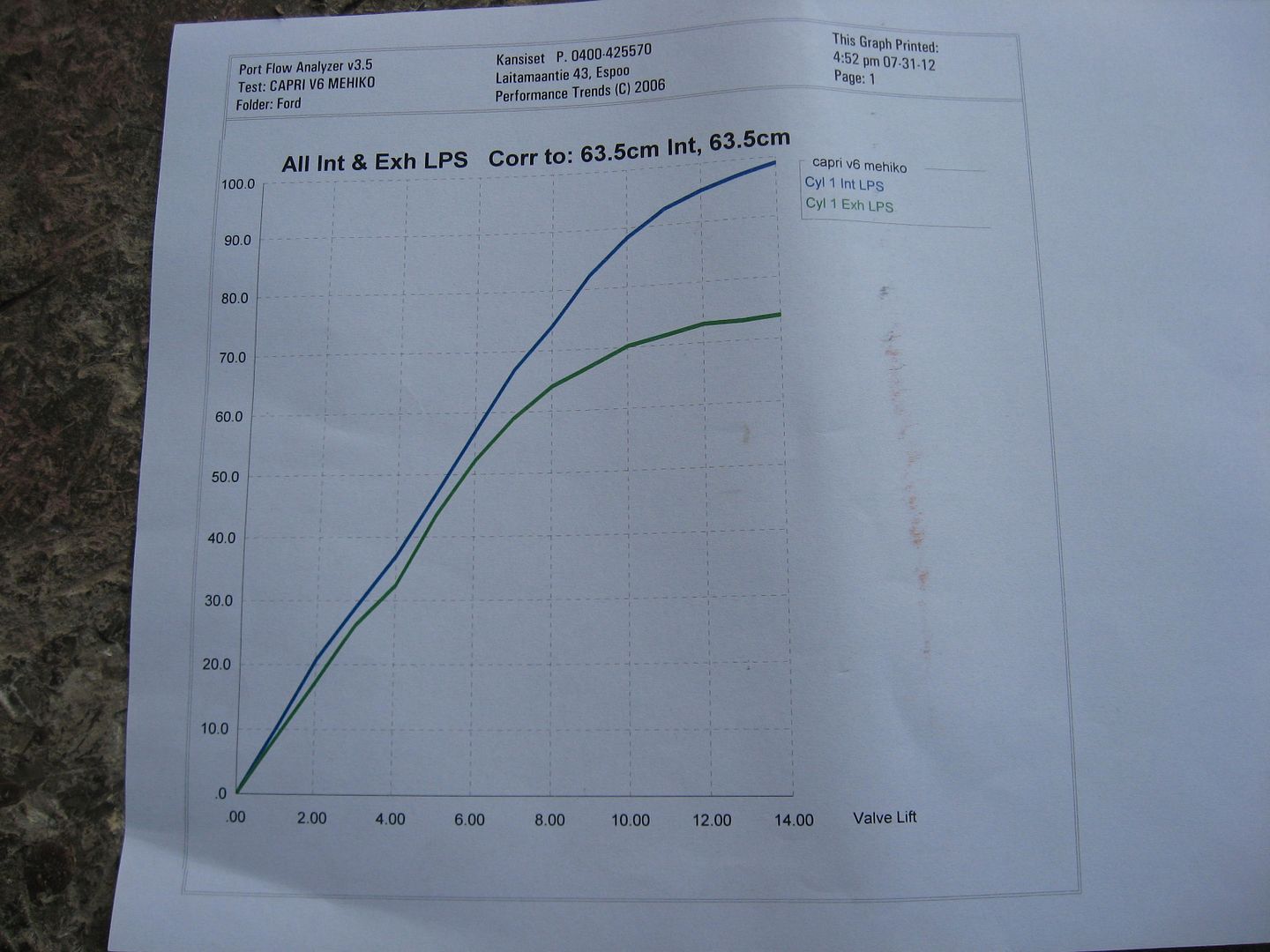

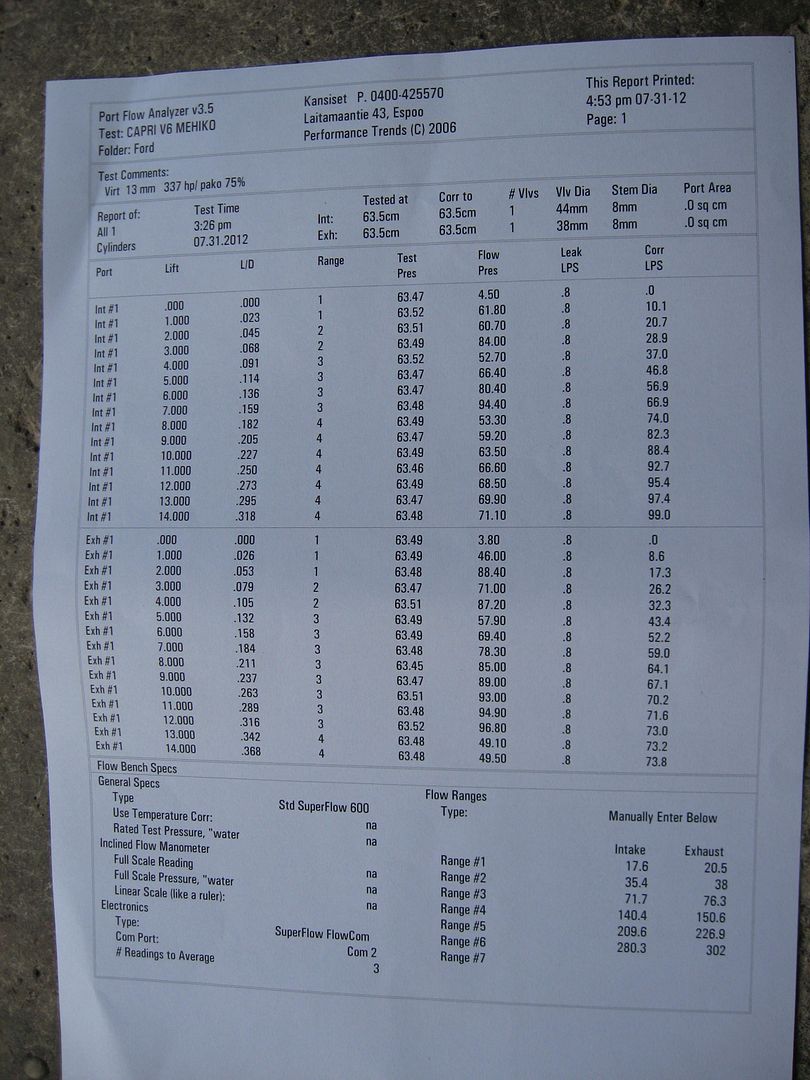

LPS = litres per second

LPS x 2.12 = CFM

So 97 LPS = 206 cfm (13 mm valve lift)

1 LPS = 0.58 horsepower

So 97 x 0.58 x 6 = 337 horsepower (6 cylinder engine)

WOT-TECH has flow numbers something like 236 cfm , .500 valve lift.

I am not going to be doubtful at all.

That is pretty much horsepower from 3400 engine.

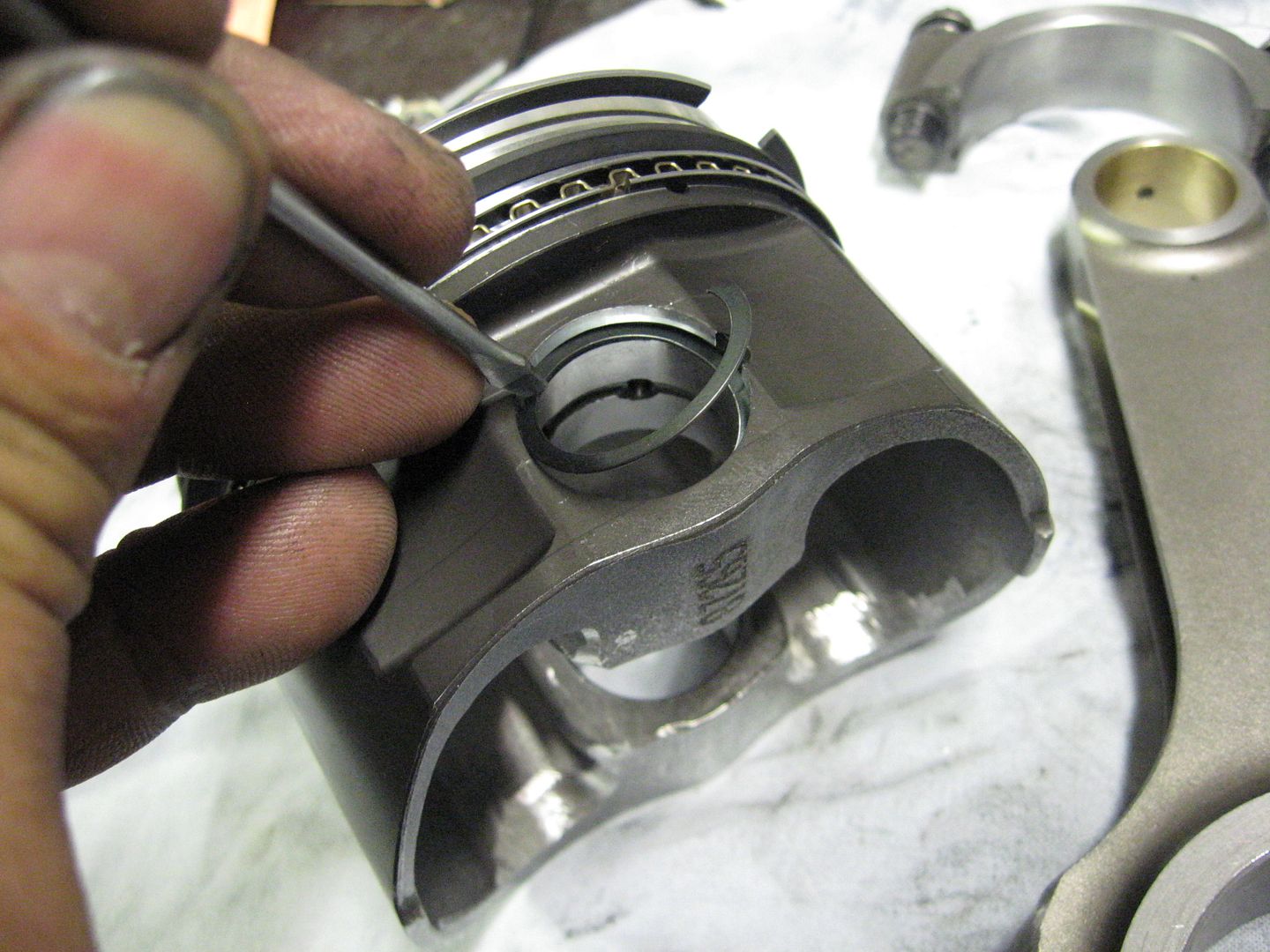

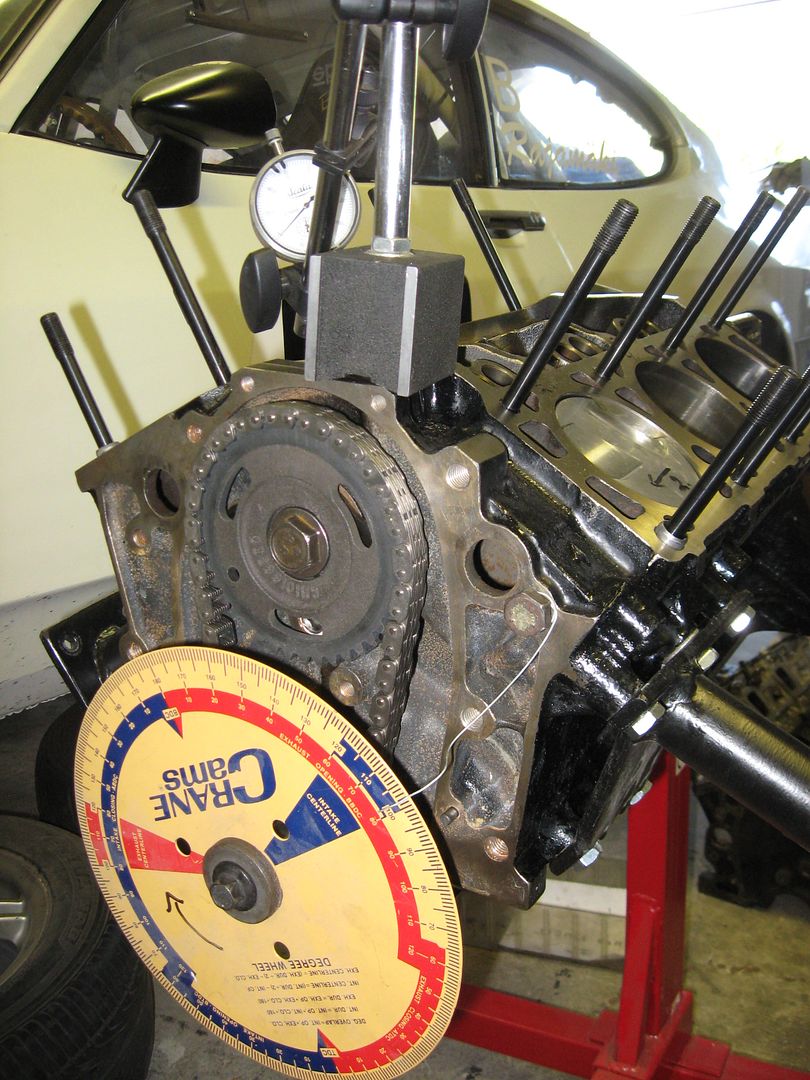

And some engine assembly pictures.

Diamond pistons bore 89.25 mm

Spirolock wrist pin locks

Intake valve full lift 102 degree

Last edited by veekuusi; 08-06-2012, 12:16 PM.

Last edited by veekuusi; 08-06-2012, 12:16 PM.

Comment

Comment