wow, for all the info you post up I'm a little surprised you can't follow this one. Not once did I quote you or the photo you posted.

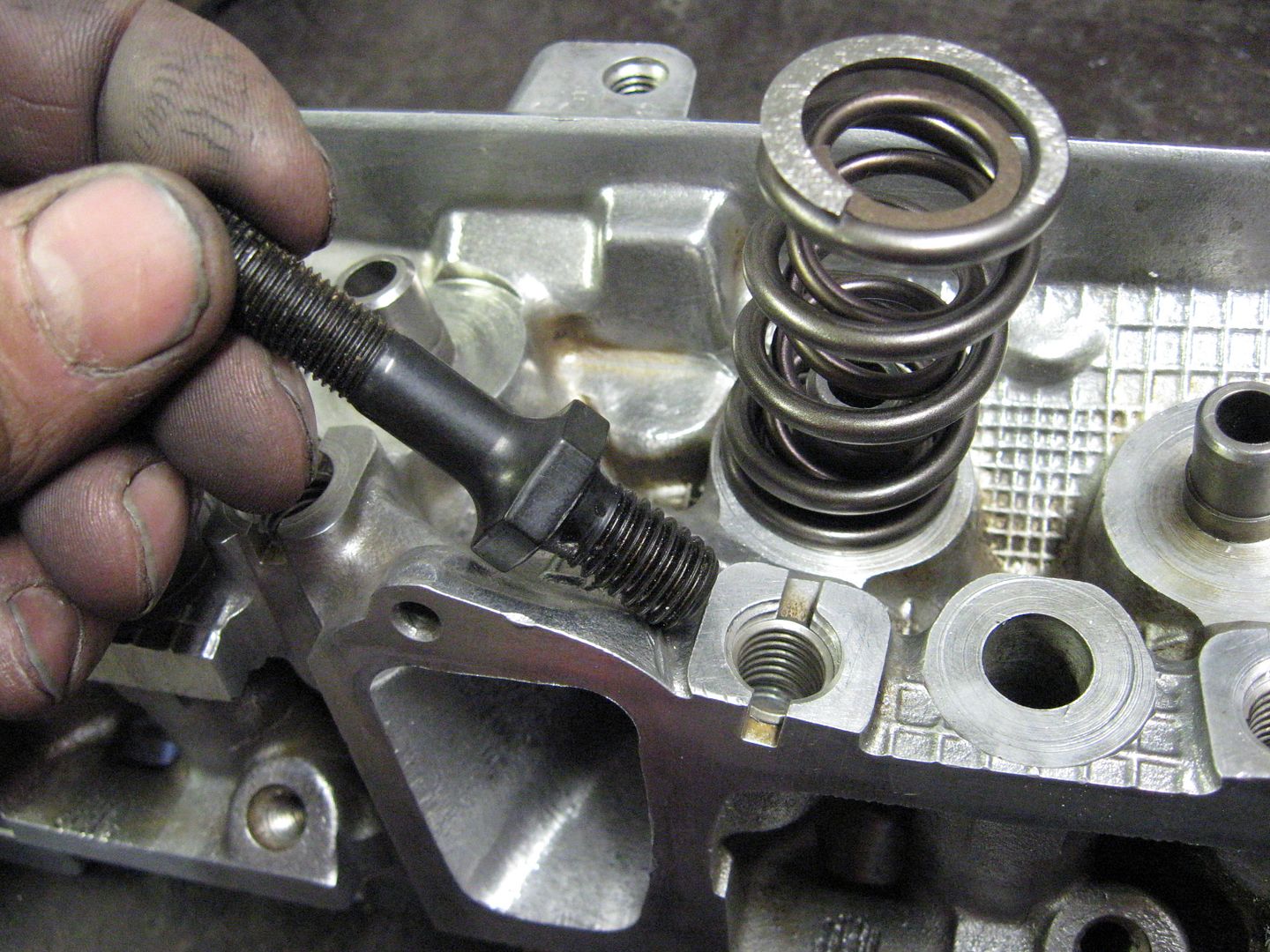

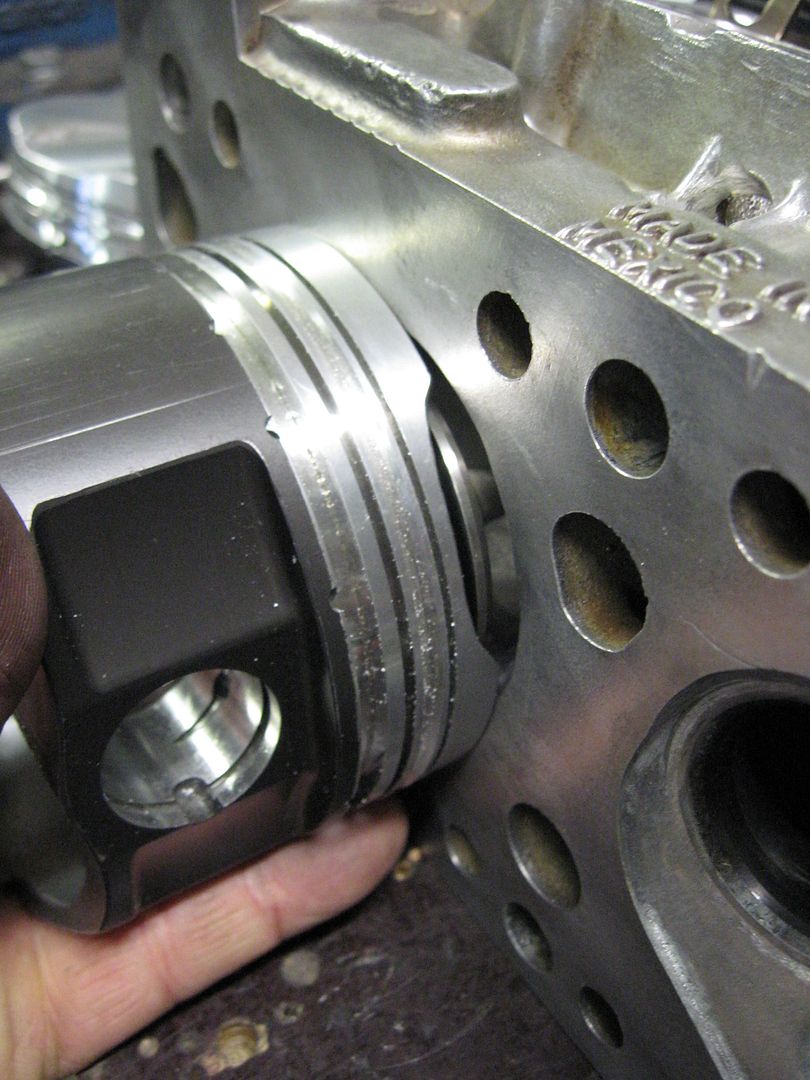

The Studs Ben sells are too long for this Original poster to use look at his pictures and posts to see why I'm not going to explain that again, Mach 5 posted up a DIFFERENT part number that would not be too long for the main's alone with 1 washer, I thought it would be a good option to use over double washer's since ARP recommends not doing that. BUT After thinking it over I'm also running a crank scraper and a windage tray so the shorter stud that Mach 5 posted is too short for me.

The Studs Ben sells are too long for this Original poster to use look at his pictures and posts to see why I'm not going to explain that again, Mach 5 posted up a DIFFERENT part number that would not be too long for the main's alone with 1 washer, I thought it would be a good option to use over double washer's since ARP recommends not doing that. BUT After thinking it over I'm also running a crank scraper and a windage tray so the shorter stud that Mach 5 posted is too short for me.

Comment