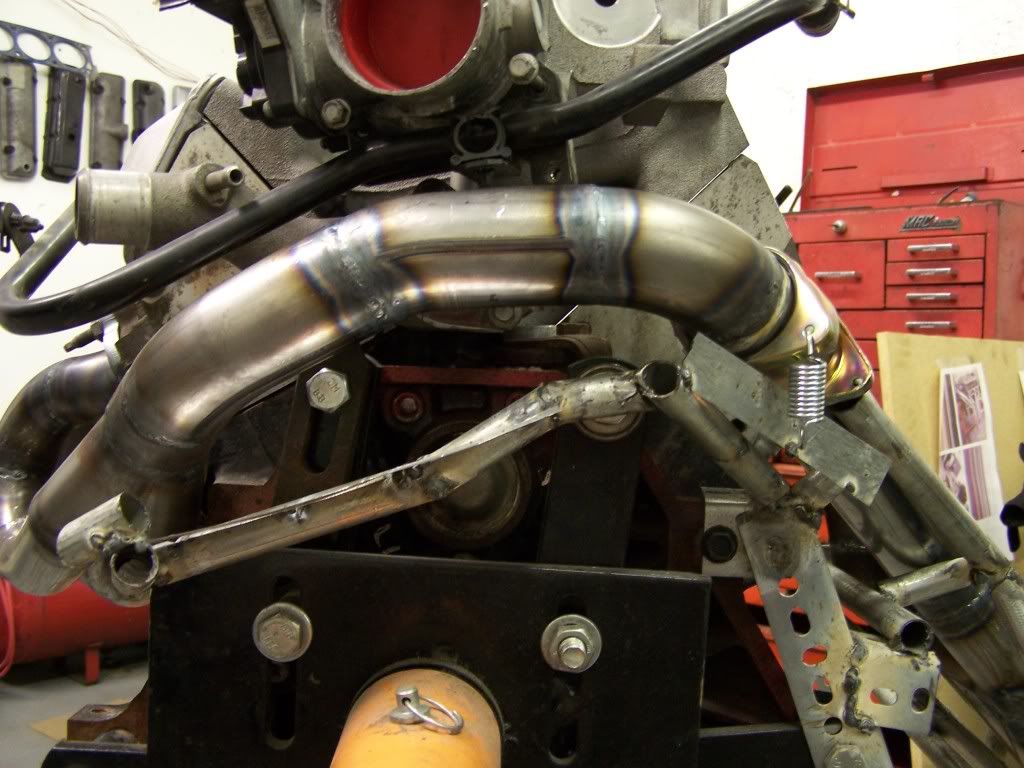

that work is kind of rough for a high dollar race team...

that much money invested and i would remade that and focused on getting rid of those cheater cuts and pie cuts. i like the gradual bend on the main tube, but it completely screws it up going with that sloppy angled "cheater cut" then pie cut. that kinda follows my idea that it does not have to be perfect to make power. that charge piping would never fly with me especially if it was a high dollar build like that. i would have done it over or made whom ever built it do it over. how ever that thing made what 1600 almost 1700whp and goes over 200mph? sloppy work but great results.

notice the thin wall collector! now that is a much better collector then i use in production. i bet that is burns 321 stainless. looks to be double slip fit and not welded too. id love to get a look at the hot parts on that thing.

Comment