My old set-up used an S256 turbo which was perfectly sized for my old 3400 and made full boost at around 2500 with good power untill 6000 rpms. It was an excellent turbo for that motor. However, after calculating the flow requirements for the new motor, I found that it begins to choke after 5000 rpms on the new 3500 motor. This motor is being built to shift at 7200rpms w/ an absolute red-line of 7500rpms, so this turbo will not do.

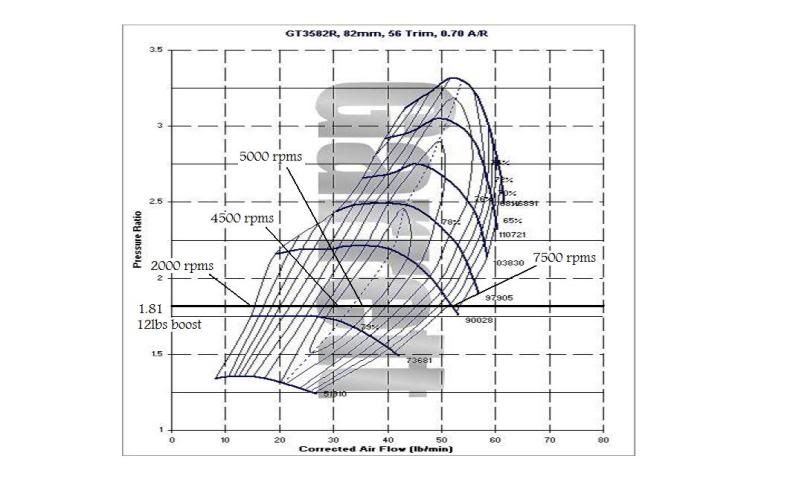

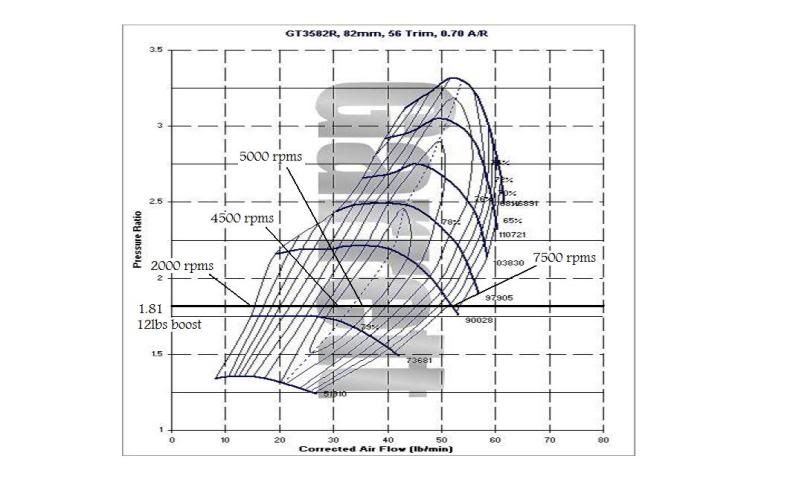

I specifically needed a turbo that would deliver 13.99 lbs/min of air-flow at 2000 rpms with a peak air-flow of 52.44 lbs/min at 7500 at a constant pressure ratio of 1.81 (about 12lbs of "pump-gas" friendly boost).

The map of the GT3582R compressor with a .70 A.R., "anti-surge" ported housing and 2.5in outlet matches that profile exactly. Ill be using a T3 .78 A.R. divided housing and quick-spool valve. Hypothetically, Full Boost should start as low 2000 rpms and remain constant without restriction untill 7495rpms. The flow rate of the map starts at the razor edge of the "surge-limit" and builds flow to the very outer edge of the "choke-limit". It builds its peak efficiency of 80% at 4500-5500rpms with no less than 72% efficiency thoughout the entire usable powerband!.

Here is a picture of the compressor map with my 3500 rpm required air-flow points super-imposed over it. Its amazing just how well the flow-map matches the air requirements of my engine.

No lag, no choking. Just a good flat air delivery profile to match powerband of the cam perfectly.

I specifically needed a turbo that would deliver 13.99 lbs/min of air-flow at 2000 rpms with a peak air-flow of 52.44 lbs/min at 7500 at a constant pressure ratio of 1.81 (about 12lbs of "pump-gas" friendly boost).

The map of the GT3582R compressor with a .70 A.R., "anti-surge" ported housing and 2.5in outlet matches that profile exactly. Ill be using a T3 .78 A.R. divided housing and quick-spool valve. Hypothetically, Full Boost should start as low 2000 rpms and remain constant without restriction untill 7495rpms. The flow rate of the map starts at the razor edge of the "surge-limit" and builds flow to the very outer edge of the "choke-limit". It builds its peak efficiency of 80% at 4500-5500rpms with no less than 72% efficiency thoughout the entire usable powerband!.

Here is a picture of the compressor map with my 3500 rpm required air-flow points super-imposed over it. Its amazing just how well the flow-map matches the air requirements of my engine.

No lag, no choking. Just a good flat air delivery profile to match powerband of the cam perfectly.

Comment