Originally posted by ForcedFirebird

View Post

Announcement

Collapse

No announcement yet.

Anyone else notice this???

Collapse

This topic is closed.

X

X

-

I did this spring in my lumina stock 3.1 #5 exhaust lobe (gen 2)1999 Olds Alero 2.4 to 3500 swap (running). totaled by a honda

1992 lumina 4 door 3500 3spd auto 15.020 @93.5 mph

1984 Cavalier type 10 hatch 3100 5spd!!!

14.96@91.47 in the 1/4

9.63@74.36 in the 1/8th

14.30 on slicks! scrapped due to rust!

-

Originally posted by 1QUICKHATCH View PostI did this spring in my lumina stock 3.1 #5 exhaust lobe (gen 2)

Hmm. Wonder if it behooves us to find a way to modify the gen3 heads for the gen1 and 2 blocks?

Comment

-

I have thought the same thing...Originally posted by SappySE107 View PostFine, I will say it again. The gen 2 and gen 3 have the same drain back holes. Gen 2 are flat tappet aluminum head, so there is nothing wrong with the design of the drain back system.

BUT when I read this thread and looked back at the iron heads (I know, kill me now), the oil drainback definitely IS in a different location, due to the iron head "siamesed" ports, yet the aluminum heads (with mani attached) seemed to have more room for oil to pass the ports into the valley after spraying from the rockers.

Either way '85 maro has already pointed out that there is a lift limit on the gen 1 block and roller lifters due to the galley.

Comment

-

Rollers cant be used in a flat tapped block because you don't have a way to mount the lifter retainers... unless your drilling and tapping the block to bolt those in.Originally posted by 85maro View PostActually I'm building a 3.4/3400 hybrid that'll have a roller cam. I took the roller off a lifter and there's no hole underneath. I haven't tried it yet (obviously) but I'm trying to dispel the idea that rollers can't be used in a flat tappet block. How did this idea start in the first place? Anyway back to the reason I started the thread which is to point out where return oil is going. Maybe this is why we hear of more tappet failures on gen 1 & 2 blocks with a hybrid conversion? If I'm not mistaken the cam is exposed to oil flung off the crank in sbc's whereas 60* v6's have a second divider in the lifter valley between the crank & cam.

60's do have a divider between the crank and cam, they are not visible to each other, so yeah most of the oiling is coming from the top end, but as others noted there is quite a bit of seepage from the lifter bores and also the lifter mains themselves.

Got Lope?

3500 Build, Comp XFI Cam 218/230 .050 dur .570/.568 lift 113LSA

Fully Balanced, Ported, 3 Angle Valve Job, 65mm TCE TB, S&S Headers.

Stage-1 Raybestos/Alto 4t60e-HD, EP LSD, 3.69FDR

12.61@105 Epping NH Oct 2015 Nitrous 100shot (melted plugs) 13.58@98.8 N/A 3200LBS

Comment

-

Aye! You never thought about it before, but the two outside pushrods will oil the other 2 areas missing in your first diagram

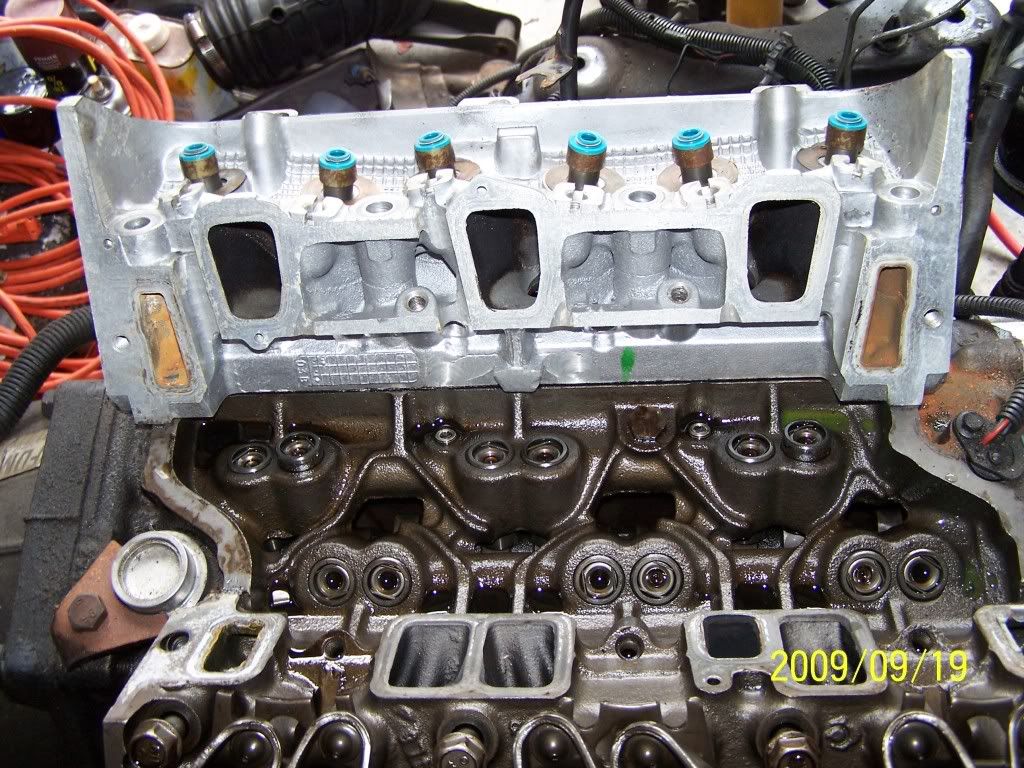

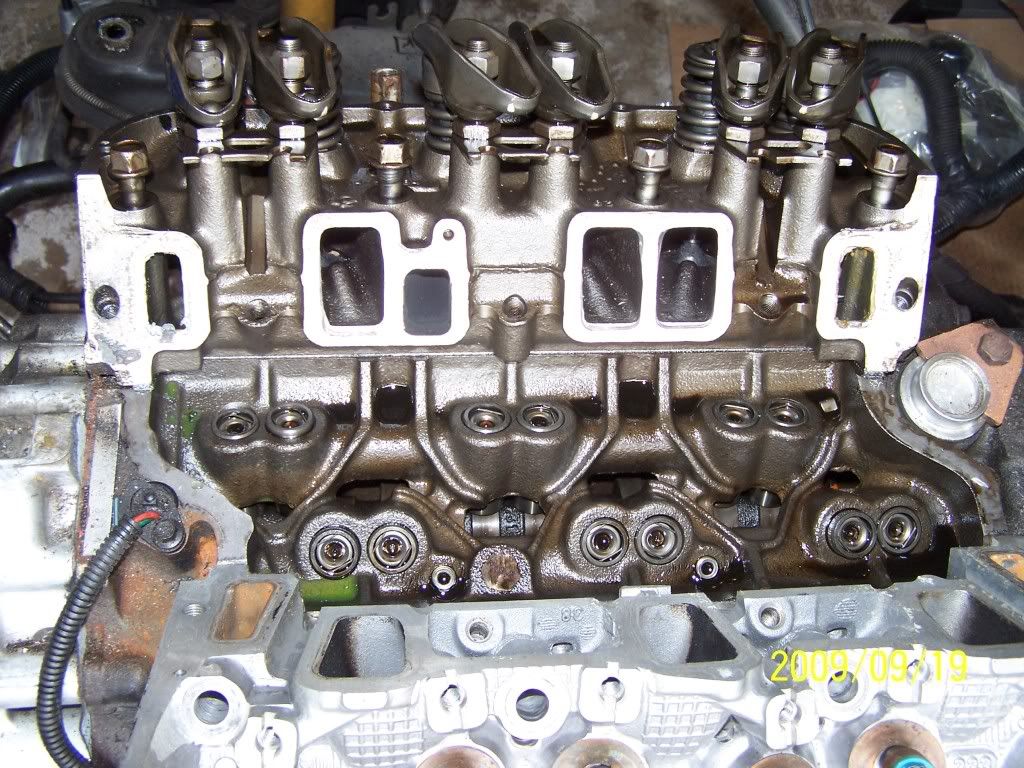

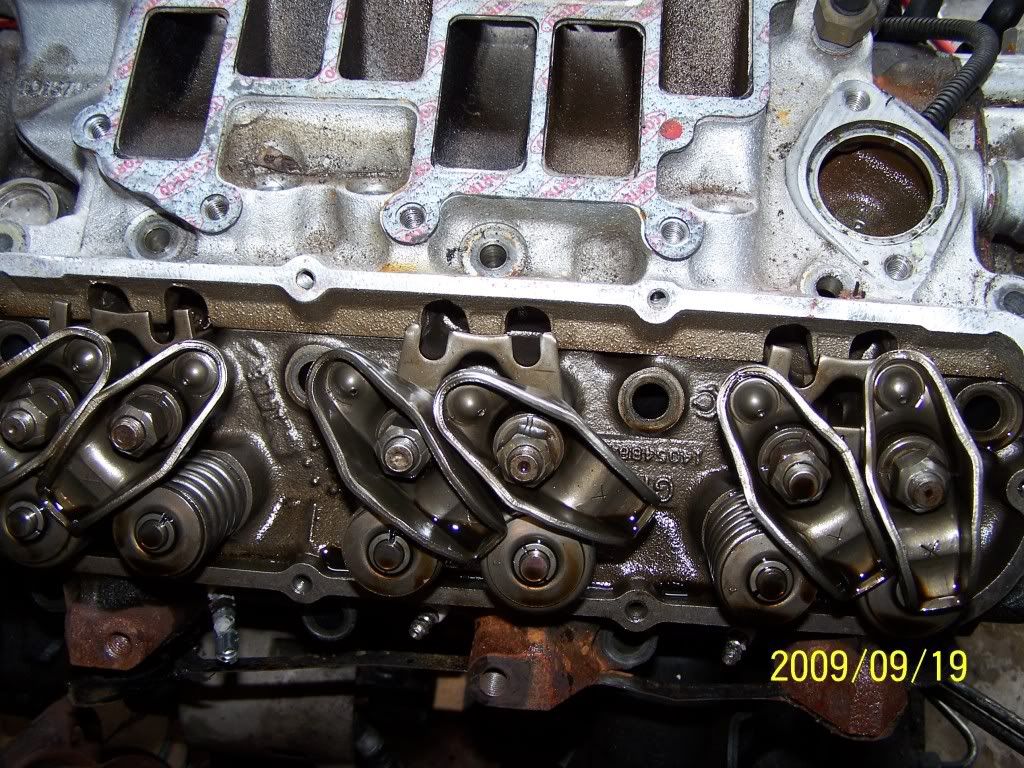

Here's some side-by-side pics to get the noggin working...

And with the manifolds attached...

Appears to me that with the iron heads, the only oil path available is the pushrods, but with the Gen3 heads, you have the pushrod paths and the extra area between the ports themselves. In your first photo with the red lines, you can add one at each pushrod as the head has a significant dip in the geology to send oil down the pushrod path.

Comment

-

I welded bolts to the block.Originally posted by 3400-95-Modified View PostRollers cant be used in a flat tapped block because you don't have a way to mount the lifter retainers... unless your drilling and tapping the block to bolt those in.

forcedfirebird- oil doesn't drain down the pushrod indentations on the alum heads, only through the 3 drilled holes. Take a look at one running w/o a valvecover. I got a look at a gen 2 block and it has the same channels as the later alum head stuff, so there's only an issue with originally iron headed stuff. The drainback holes and the channels in the block don't send oil to all the holes, cyls 2 & 5 don't get anything. IDK how this will really effect things, but I tapped 2 of the drainback holes to reroute oil.Increasingly I find the difference between a "fact" and an opinion is the number of people who believe it.

3.4 block converted to roller valvetrain with 220/225 cam on 115 lsa, '769' heads with 3500 valves, LS6 springs & porting, twin T04E turbos, 3500 plenum with ported 3400 lower & 'short star' 65mm throttle.

Comment

-

You mean the webs on the block are like Gen3?Originally posted by 85maro View PostI welded bolts to the block.

forcedfirebird- oil doesn't drain down the pushrod indentations on the alum heads, only through the 3 drilled holes. Take a look at one running w/o a valvecover. I got a look at a gen 2 block and it has the same channels as the later alum head stuff, so there's only an issue with originally iron headed stuff. The drainback holes and the channels in the block don't send oil to all the holes, cyls 2 & 5 don't get anything. IDK how this will really effect things, but I tapped 2 of the drainback holes to reroute oil.

Comment

-

Didn't the gen 2 blocks get crank priority oiling with three galleries instead of just the two in the gen 1 blocks? It may not be true main priority but if it has the three gallaries then that's a major difference. In the gen 1 blocks oil comes from the filter, up to the left lifter bore/gallery, then down to the cam journals. There are holes in the cam journals that lead down to the mains as well as another leading to the right lifter bore/gallery. I had always heard that this is the reason gen 1 blocks can't support rollers; that right lifter bore isn't getting full pressure, etc.Wayne

'94 3.4L V6 Camaro 5-spd

Custom TO4E-T3 Turbo/Intercooler Setup

Megasquirt Stand-alone EFI (www.megasquirt.info) controlling fuel and ignition timing

My Megasquirt 3.4L F-body Install Guide:

http://www.turbocamaroproject.com/me...tallGuide.html

Comment

-

did gen 3 also begin the roller 60's? If so then my statement should still mean something. Wayne

Wayne

'94 3.4L V6 Camaro 5-spd

Custom TO4E-T3 Turbo/Intercooler Setup

Megasquirt Stand-alone EFI (www.megasquirt.info) controlling fuel and ignition timing

My Megasquirt 3.4L F-body Install Guide:

http://www.turbocamaroproject.com/me...tallGuide.html

Comment

-

No, as far as I know the Gen 2 blocks had the same oiling as the Gen 1. However, The Gen 2 heads have those same holes for the oil to drain back unlike the Gen 1 heads that had the oil spill over the top (at least thats how it appears in the pic, never seen a Gen 1 up close). That was the entire point Ben has tried to make twice now. I am sure tens of thousands of Gen 2 motors have seen service in excess of 200K miles (I know I owned one) with the oiling set up the same way that a Gen 1 block with Gen 3 heads has.

As for the roller lifters working with that setup, it remains to be seen. In theory it could work but I am no engineer so I couldn't guess if it would work or if the longevity of the lifters would be comparable to the Gen 3 motors. I can say the GM engineers probably didn't add the extra oiling at the same time as the roller lifters for nothing.

EDIT - Looks like I got beat to the punch Last edited by WrathOfSocrus; 09-22-2009, 01:02 AM.

Last edited by WrathOfSocrus; 09-22-2009, 01:02 AM.

Comment

-

The Chevy 4.3L V6 uses the same oiling system as our gen I and II blocks but it uses the same roller lifters as any Small Block, So does the Buick. Also keep in mind there are several roller lifter retrofit kits out there to convert motors to roller lifters and they also do not have priority main oiling. So it is very feasible to install roller lifters in a Gen I block as long as you can retain the lifters and control cam thrust.1993 EXT. CAB, 3.4L V6 TBI, 5spd manual. Sonoma

1990 4Door, 3.2L V6 TBI, 5spd manual. 4X4. Trooper

Because... I am, CANADIAN

Comment

Comment