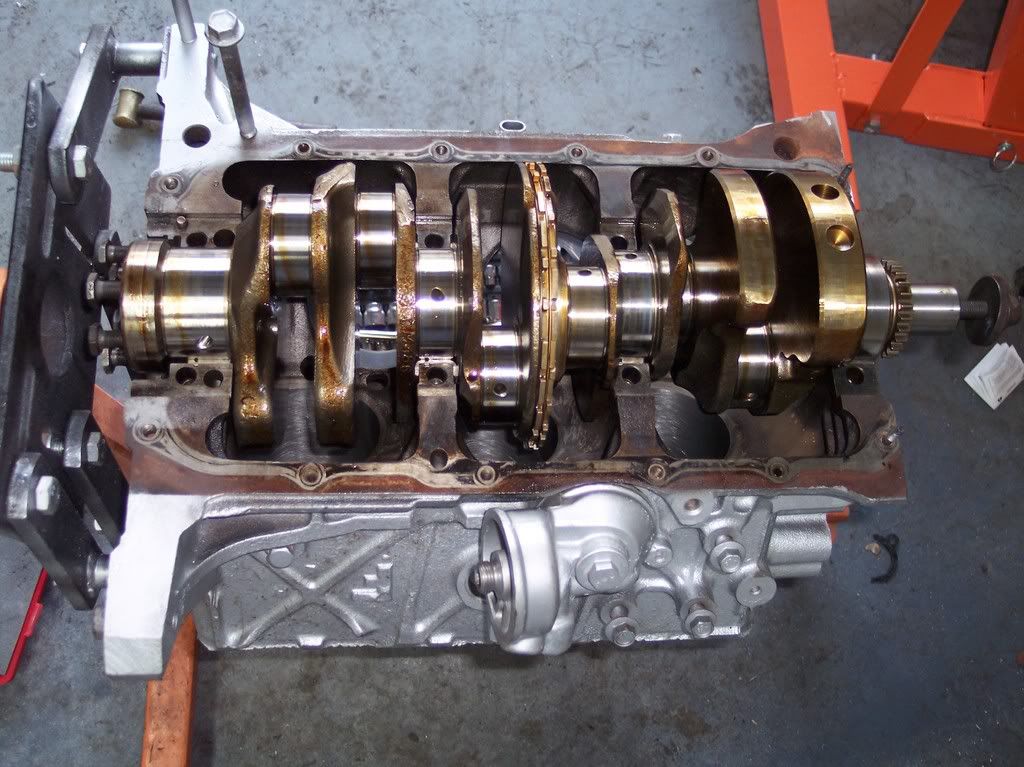

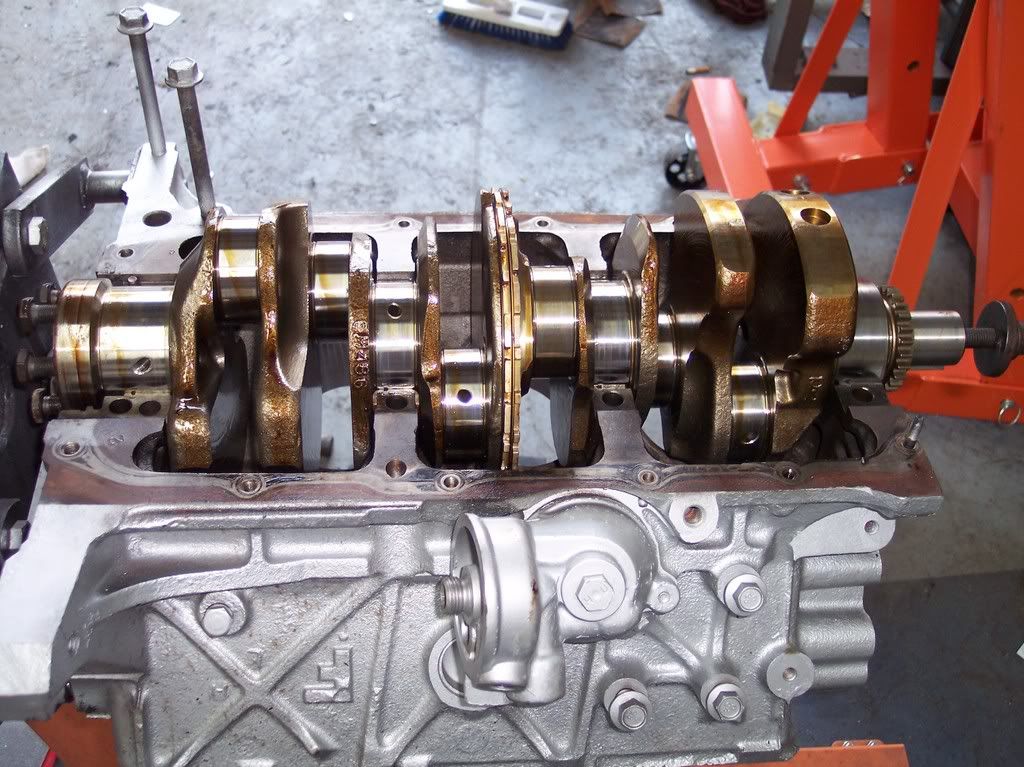

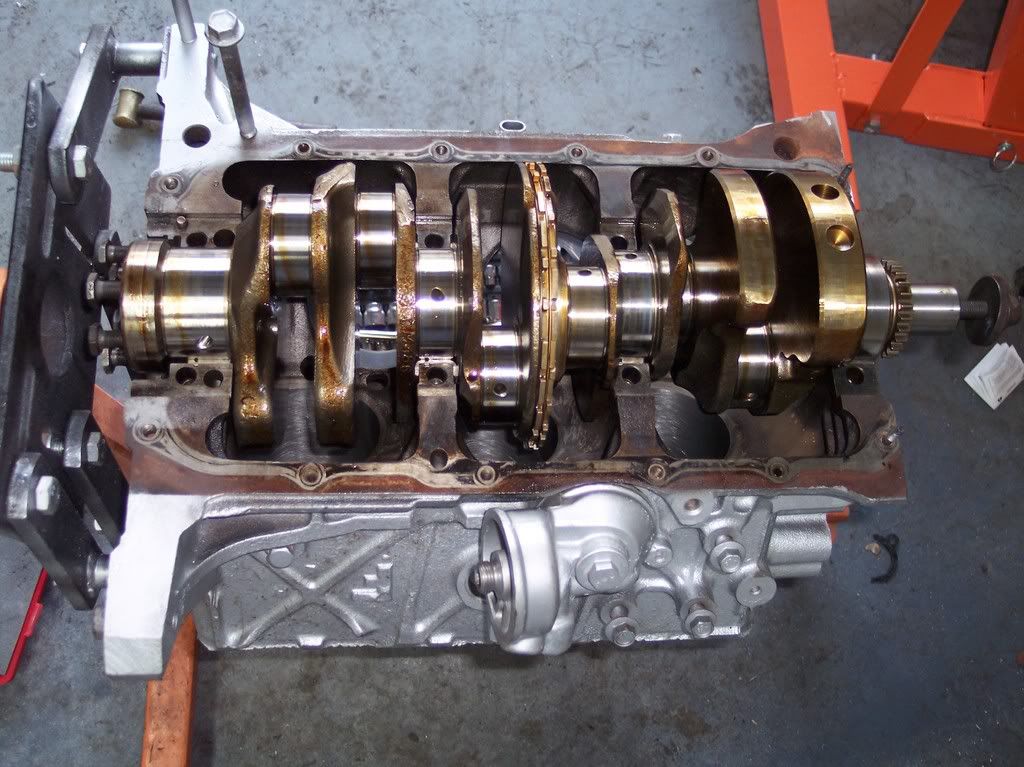

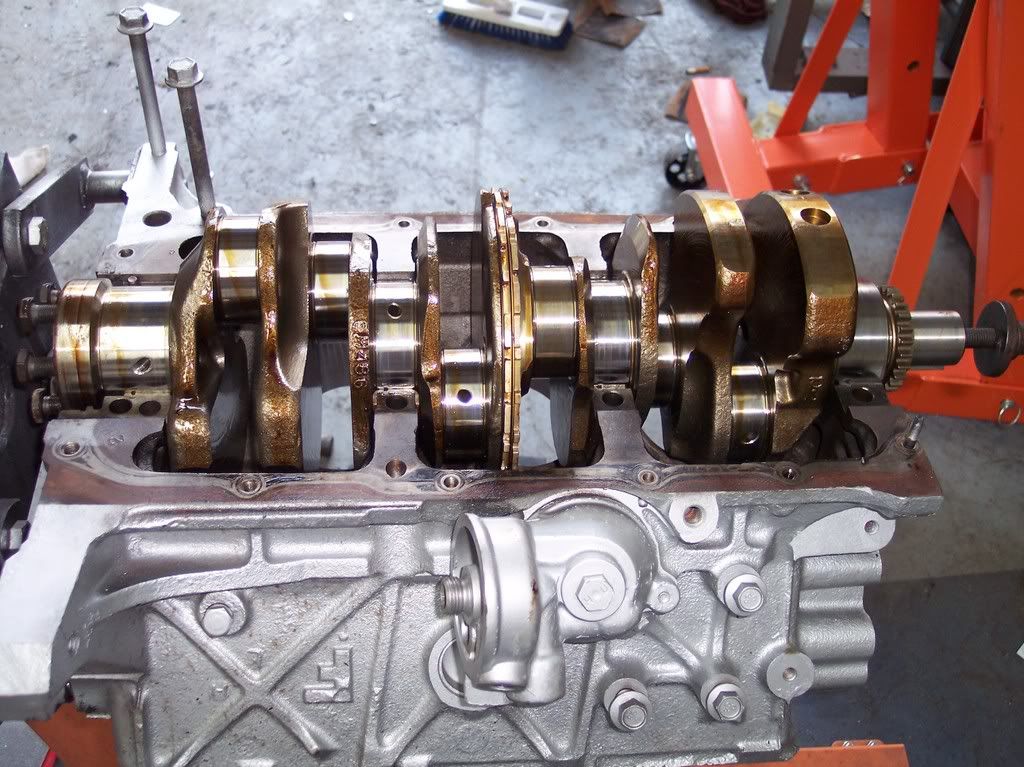

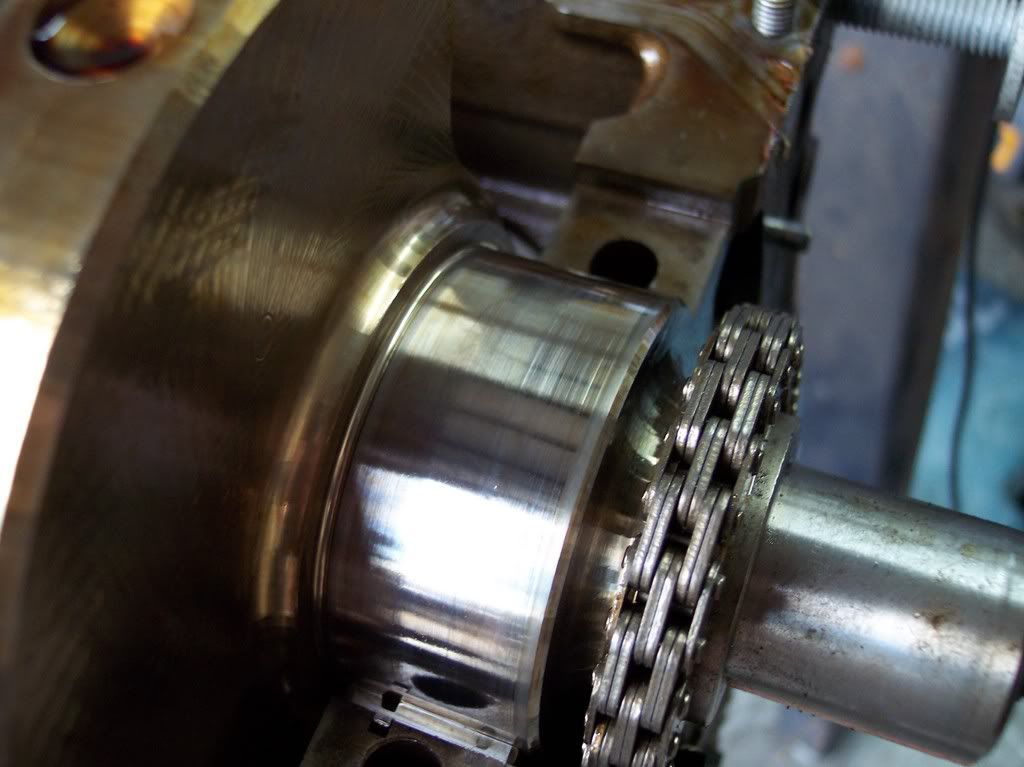

I put a 3500 crank in my 3.4, but didn't take the time to press out the wristpins on the 3500 pistons. Instead I bolted the rod on the crank with the piston sticking out the bottom, lol. Since the rod cap and the heads of the bolts measured almost the same distance from the bearing, then I felt it was a productive test (actually the nut side of the bolt was a little further).

The idea is to check clearances for stroking a Gen1 block. Since the 3500 and Gen 1 rods have the same thickness caps, I feel that if a 3500 rod made it around, then a stroked 3.4 rod would also clear. There was only one spot that the rod bolt hit the block, and that was only if I turned the rod on the crank in such a way that would never happen with a piston in the bore.

Since we know the 3500 has plenty of clearance, and that's the next motor going in my car, stroking is a serious consideration. I know for the average person, this might get out of budget really fast, but having a machine shop makes it feasable for me to try. The only part I think I will have to sub out is the final grind on the rod journals.

Also I was going to measure the rod pins on both the 3.4 and 3500, but didn't have a caliper handy that was thin enough to get between the rod and piston (also was wanting to get the crank and bearings installed today on my block), but I have plenty of extar rods with pistons on to measure later.

Here's pics...

The idea is to check clearances for stroking a Gen1 block. Since the 3500 and Gen 1 rods have the same thickness caps, I feel that if a 3500 rod made it around, then a stroked 3.4 rod would also clear. There was only one spot that the rod bolt hit the block, and that was only if I turned the rod on the crank in such a way that would never happen with a piston in the bore.

Since we know the 3500 has plenty of clearance, and that's the next motor going in my car, stroking is a serious consideration. I know for the average person, this might get out of budget really fast, but having a machine shop makes it feasable for me to try. The only part I think I will have to sub out is the final grind on the rod journals.

Also I was going to measure the rod pins on both the 3.4 and 3500, but didn't have a caliper handy that was thin enough to get between the rod and piston (also was wanting to get the crank and bearings installed today on my block), but I have plenty of extar rods with pistons on to measure later.

Here's pics...

Comment