I was looking at the 62mm throttle body and I have a question. Is there any way to make cables pull from the rear of the assembly? This is going on a 3.1 in my 1991 Camaro. Would my linkage work if I flipped it upside down? Its kinda hard for me to try to picture it.

Announcement

Collapse

No announcement yet.

TCE throttle body question

Collapse

X

-

Tags: None

-

Just use a throttle cable from a 4.3 Vortech truck. They are long enough to reach around the TB.

I haven't seen a TCE TB in person, but if they are like all the other TB's I have, then you can take the cam (linkage) off your stocker and weld (or drill/tap/bolt) it to the shaft in the other TB. I did it on the 75mm N* TB that Dave took from me.

Comment

-

All of the newer TCE TBs are machined to be used as front or rear pull. A threaded hole for an idle stop is already in place for rear pull. The only modification required is to remove the locating tab from the TPS so it can be rotated 180 degrees with the shaft.

Below is a TCE 65mm TB mounted to a 3500 in an MG that is setup as rear pull. It gets pretty decent gas mileage and should easily run in the 13s.

MinusOne - 3100 - 4T60E

'79 MGB - LZ9 - T5

http://www.tcemotorsports.com

http://www.britishcarconversions.com/lx9-conversion

Comment

-

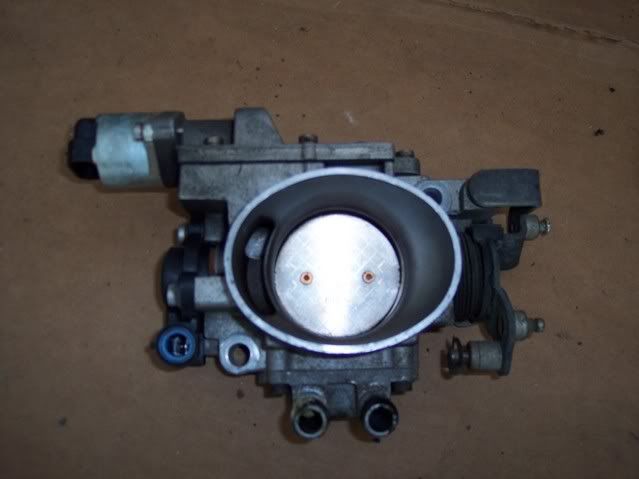

Thats good to know. But I just want to be certain before I make plans. Here is a pic of my linkage. Will this work rotated 180 degrees or will I have to get a different linkage?Originally posted by CNCguy View PostAll of the newer TCE TBs are machined to be used as front or rear pull. A threaded hole for an idle stop is already in place for rear pull. The only modification required is to remove the locating tab from the TPS so it can be rotated 180 degrees with the shaft.

Below is a TCE 65mm TB mounted to a 3500 in an MG that is setup as rear pull. It gets pretty decent gas mileage and should easily run in the 13s.

My CarDomain Site--------The Camaro Song

My CarDomain Site--------The Camaro Song

Comment

-

I really do not know.... everyone so far has used the shaft, IAC & TPS from a FWD TB. There are several issues like shaft diameter, screw hole locations for the throttle plate, spring location and how the shaft drives the TPS. Sorry that I can not give you more info.Originally posted by grimmcs View PostWill this work rotated 180 degrees or will I have to get a different linkage?

Also... I just noticed that the mounting holes are also in the wrong place. Yours are at 2 & 8 o'clock while the FWDs are at 4 & 10 o'clock. I do not know if the spread is the same or not.MinusOne - 3100 - 4T60E

'79 MGB - LZ9 - T5

http://www.tcemotorsports.com

http://www.britishcarconversions.com/lx9-conversion

Comment

-

Here is a pic so we can clarify what my 3.1 TB looks like.

My CarDomain Site--------The Camaro Song

My CarDomain Site--------The Camaro Song

Comment

-

Perhaps I should clarify the FWD statement. The billet TBs were designed for GEN-III FWD engines which have the bolt holes at 4 & 10 o'clock. The store has a pic that you can use for comparison.

MinusOne - 3100 - 4T60E

'79 MGB - LZ9 - T5

http://www.tcemotorsports.com

http://www.britishcarconversions.com/lx9-conversion

Comment

-

Let me tell you a story....

The TCE TBs are designed for a 3x00 TB bolt pattern, and as Marc stated, that makes the bolt holes in the wrong corners. If you are planning on using a 3x00 top end, then its possible to either flip the TB over or just put the shaft in from the opposite direction. But, from reading your original post, that's not what it sounds like. Sounds like you are maintaining your 3.1L plenum. So, here is where the story comes in.

Back in 2000/01, I was the first person to put a billet 62mm TB on a 3100. Problem was, the TB I was using was designed for the 2.8/3.1L engines. So I ran into the bolt holes being on opposite corners issue. What I ended up doing was making an adapter plate out of 1/2" aluminum. It was bolted to the plenum, and I drilled clearance holes in the TB for the heads (could have possibly used coutnersunk screws as well). Then the opposite corners were tapped for the mounting of the TB. It added extra cost to the project, but at the time, it was really the only thing out there. Needless to say, my experience led to the redesign of the original TB into a 3x00 model.

Some issues you need to be aware of with the 62mm TB on the store is there are no provisions for the vacuum blcok that you currently have in the IAC plate. So you would have to figure out a fix to that as well. I think the throttle pulling from the back is the least of your worries.

I'll try to dig up some pictures of my install for you to look at.-Brad-

89 Mustang : Future 60V6 Power

sigpic

Follow the build -> http://www.3x00swap.com/index.php?page=mustang-blog

Comment

-

Grimm is in the same boat as me. We are using Gen3 top ends in 3rd Gen FbodiesOriginally posted by CNCguy View PostPerhaps I should clarify the FWD statement. The billet TBs were designed for GEN-III FWD engines which have the bolt holes at 4 & 10 o'clock. The store has a pic that you can use for comparison.

http://www.60degreev6.com/store/inde...d&productId=23 .

.

Comment

-

Pics...

-Brad-

-Brad-

89 Mustang : Future 60V6 Power

sigpic

Follow the build -> http://www.3x00swap.com/index.php?page=mustang-blog

Comment

-

Yeah sorry about the confusion. I am going to use the Gen III heads/intake. Im so used to talking about it at TGO I forgot to mention that.Originally posted by ForcedFirebird View PostGrimm is in the same boat as me. We are using Gen3 top ends in 3rd Gen Fbodies .My CarDomain Site--------The Camaro Song

.My CarDomain Site--------The Camaro Song

Comment

Comment