While I'm waiting for some other parts and the opportunity to work on this to happen... I just want to mention why doing something like this is so very critical to our engines... in particular for the process of breaking in the camshaft lobes on a fresh engine build...or in the case of an engine that has had to sit in someone's garage for years on end. It has been argued here that all one needs to do to avoid having to go through all of this rigmarole is pull the ICM connectors, top off the oil level...and crank away like hell to restore oil pressure. In some cases...many people would just say, "F*ck it! Crank it up and lets see what happens!" Okay... if you think so... But...

Well... whether new or old...so many bad things can happen it is not funny. In the case of new or newly rebuilt engine... starting a motor that does not have a perfectly pressurized stream of oil mixed with ZDDP and other break-in additives surrounding and pressing on all the critical moving parts can either add 10,000 to 15,000 miles of wear in just a few minutes at the very least ...or in the worst case scenario ...wipe the lobes off of a brand new cam shaft as though you threw a bucket of sand in these moving parts. In the case of the camshaft lobes in non-roller lifter style engines...the pressurized oil containing ZDDP (Zinc Dialkyl Dithio Phosphate) gets squeezed incredibly tight between the faces of the hydraulic flat tappet lifters and the lobes of the camshaft and that super pressure serves to chemically harden and strengthen the metals in contact at around 2,000 RPM. This takes about 25-30 minutes, after which, the camshaft and lifters will have been nicely "cured" for the life of the engine.

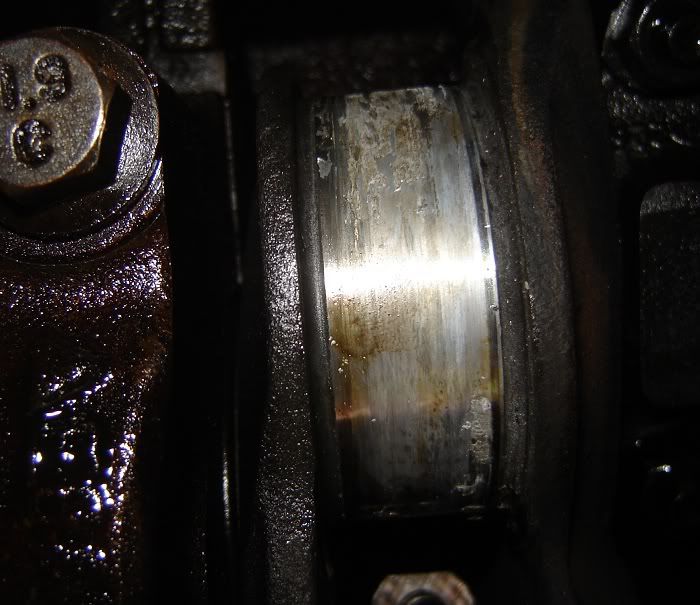

This process cannot take place where there is no oil pressure to be found as is always the case with an un-primed new engine, newly re-built engine or any engine that has been sitting for years on end. In the case of the bearing surfaces of the crankshaft... it is the very hydraulic pressure itself which ensures the long life of an engine because when so pressurized...the moving journals and connecting rods are separated from their mating bearing surfaces by the thinnest slick of oil that acts as a barrier against all the churning, turning and often pounding forces of all these internal moving engine parts that are changing direction tens of thousands of times a minute...perhaps for millions of revolution cycles during the life of the engine. Preventing journal and bearing surface damage from occurring is simply impossible without a reliable and constant supply of oil to lubricate, cool and cycle fresh lubricant in and out every properly running motor... like a blood supply. In order for this to even begin properly... that "Blood Supply" must be where it needs to be...in abundance and of the right type..BEFORE.. the engine is ever turned over from the forces of Four Stroke Combustion.

If you want a real world analogue of this process, you only have to rub the palms of your hands together for a few seconds to feel the heat of friction develop very quickly. Now just imagine if you could do that at the rate of several thousand cycles. Without some type of lubricant in between ...your hands would burst into flames! When the metal parts of an engine come into direct contact with one another... in the absence of lubrication, they tend to heat up very rapidly and expand towards each other. The resulting expansion is what happens when bearing surfaces melt and are wiped out. In the cases of piston rings fusing to and literally welding themselves to the cylinder walls, the super strong connecting rods can bend like taffy. The list goes on an on as these illustrations prove that the single most critical activity happening to keep your engine alive...is having the proper kind and amount of oil under proper pressure inside your engine. So with all that said... I think that projects like the "Oober-Loober", if successful in design and function, can make a mechanic breath a sigh of relief just knowing that: "The engine he is about to Start... will NOT come apart!" When I have worked out all the initial design and function issues, I'm confident this gizmo really will do the job right.

And just for grins...or in my case "Cringes" here are some live videos of engines being deliberately destroyed when Motor Oil is replaced with a mixture of Water and Sodium Silicate...

How 'bout this Ford Explorer going "Tits Up" during a live video of this intentional engine seizing activity at a dealership doing do for the very first time...

Water and Sodium Silicate.... Uhhhh.... NOT good replacements for Good Ol' Motor Oil!

A Dying Volvo.... Listen to the awful groans!

Well... whether new or old...so many bad things can happen it is not funny. In the case of new or newly rebuilt engine... starting a motor that does not have a perfectly pressurized stream of oil mixed with ZDDP and other break-in additives surrounding and pressing on all the critical moving parts can either add 10,000 to 15,000 miles of wear in just a few minutes at the very least ...or in the worst case scenario ...wipe the lobes off of a brand new cam shaft as though you threw a bucket of sand in these moving parts. In the case of the camshaft lobes in non-roller lifter style engines...the pressurized oil containing ZDDP (Zinc Dialkyl Dithio Phosphate) gets squeezed incredibly tight between the faces of the hydraulic flat tappet lifters and the lobes of the camshaft and that super pressure serves to chemically harden and strengthen the metals in contact at around 2,000 RPM. This takes about 25-30 minutes, after which, the camshaft and lifters will have been nicely "cured" for the life of the engine.

This process cannot take place where there is no oil pressure to be found as is always the case with an un-primed new engine, newly re-built engine or any engine that has been sitting for years on end. In the case of the bearing surfaces of the crankshaft... it is the very hydraulic pressure itself which ensures the long life of an engine because when so pressurized...the moving journals and connecting rods are separated from their mating bearing surfaces by the thinnest slick of oil that acts as a barrier against all the churning, turning and often pounding forces of all these internal moving engine parts that are changing direction tens of thousands of times a minute...perhaps for millions of revolution cycles during the life of the engine. Preventing journal and bearing surface damage from occurring is simply impossible without a reliable and constant supply of oil to lubricate, cool and cycle fresh lubricant in and out every properly running motor... like a blood supply. In order for this to even begin properly... that "Blood Supply" must be where it needs to be...in abundance and of the right type..BEFORE.. the engine is ever turned over from the forces of Four Stroke Combustion.

If you want a real world analogue of this process, you only have to rub the palms of your hands together for a few seconds to feel the heat of friction develop very quickly. Now just imagine if you could do that at the rate of several thousand cycles. Without some type of lubricant in between ...your hands would burst into flames! When the metal parts of an engine come into direct contact with one another... in the absence of lubrication, they tend to heat up very rapidly and expand towards each other. The resulting expansion is what happens when bearing surfaces melt and are wiped out. In the cases of piston rings fusing to and literally welding themselves to the cylinder walls, the super strong connecting rods can bend like taffy. The list goes on an on as these illustrations prove that the single most critical activity happening to keep your engine alive...is having the proper kind and amount of oil under proper pressure inside your engine. So with all that said... I think that projects like the "Oober-Loober", if successful in design and function, can make a mechanic breath a sigh of relief just knowing that: "The engine he is about to Start... will NOT come apart!" When I have worked out all the initial design and function issues, I'm confident this gizmo really will do the job right.

And just for grins...or in my case "Cringes" here are some live videos of engines being deliberately destroyed when Motor Oil is replaced with a mixture of Water and Sodium Silicate...

How 'bout this Ford Explorer going "Tits Up" during a live video of this intentional engine seizing activity at a dealership doing do for the very first time...

Water and Sodium Silicate.... Uhhhh.... NOT good replacements for Good Ol' Motor Oil!

A Dying Volvo.... Listen to the awful groans!

Comment