Since I've got my hands on 2 3500 shortblocks right now, and Colin also has one, I think we need to start a thread describing the differences between the 3500 and the previous 3x00 engines. As I continue to look at the 3500 I have torn apart and one of the 3100s I have, I am noticing more and more differences, from subtle to extreme. Whenever possible, I'd like to include comparison pictures as well. Marty will have his hands on one of these 3500s soon as well, so he can join in the search. If anyone else has one of these (Ben and Phil, you guys can help with the top-end), lets see if we can get a good list going and eventually make an article out of it.

To start out (and I'll add pictures later), one thing I noticed last night was that there are a couple differences between the oil pans.

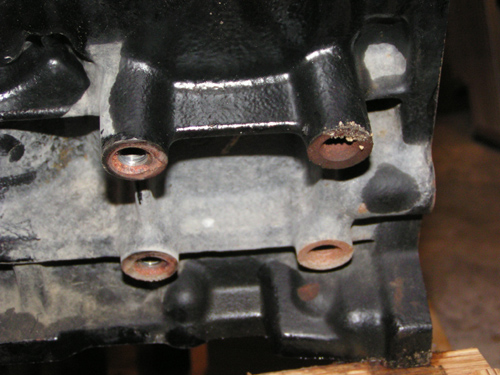

Oil Pan

- There is 1 bolt hole that is in a different location.

- Notched areas (6) in order to rod clearances (mirrored from the block)

- No oil level switch. I think this is on newer 3x00s as well. Why they got rid f it, who knows.

To start out (and I'll add pictures later), one thing I noticed last night was that there are a couple differences between the oil pans.

Oil Pan

- There is 1 bolt hole that is in a different location.

- Notched areas (6) in order to rod clearances (mirrored from the block)

- No oil level switch. I think this is on newer 3x00s as well. Why they got rid f it, who knows.

Comment