OK, I've been gathering information and parts for my 3100 swap into my 4x4 for a while now. At this point, I have a couple of problems to deal with. They're not huge, but they will cost some money and I feel like I'm at a decision point.

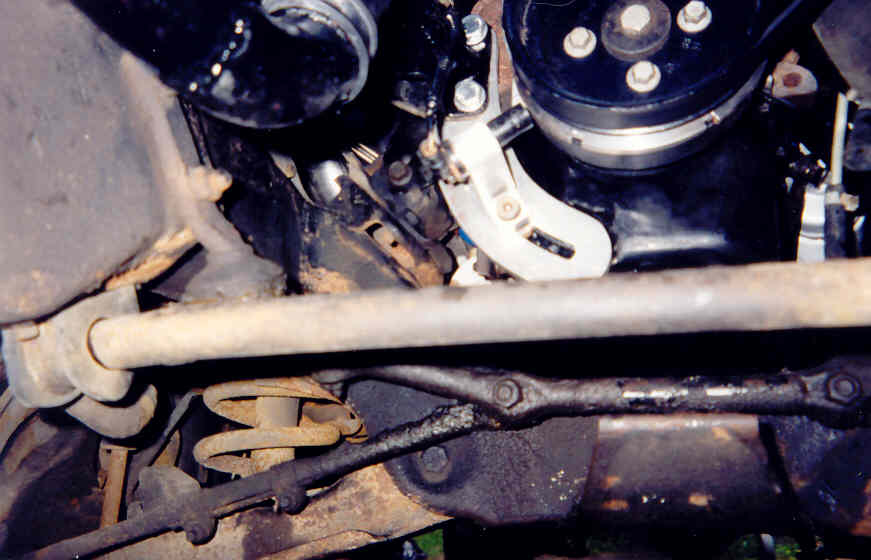

I have, in my posession, a 2002 Buick Century engine that ony has 27K on it. Unfortunately, the oil pan will not work in my 4x4s configuration. When I purchased the engine, I mistakenly thought that I could just use a pan off of one of the older engines with a little modification. This doesn't appear to be the case, so I"m stuck with trying to fabricate an oil pan which is out of my league. Also, the stock pan is aluminum which makes cutting and combining two pans unlikely without some serious money. I don't even know if they made 660 4x4 pans in aluminum. Anyway, that is going to cost some money to overcome since I'll have to farm it out.

Another problem is that the motor mounts on the engine are fairly expensive since there aren't really any RWD mounts out there for the drivers side. I'm looking at about $200 for a set of unwelded mounts, plus the cost of having them welded together (I suck at welding and wouldn't want to assemble the mounts. )

So, at this point, I figure that I'm out about $500 or so at least on top of whatever other problems come up.

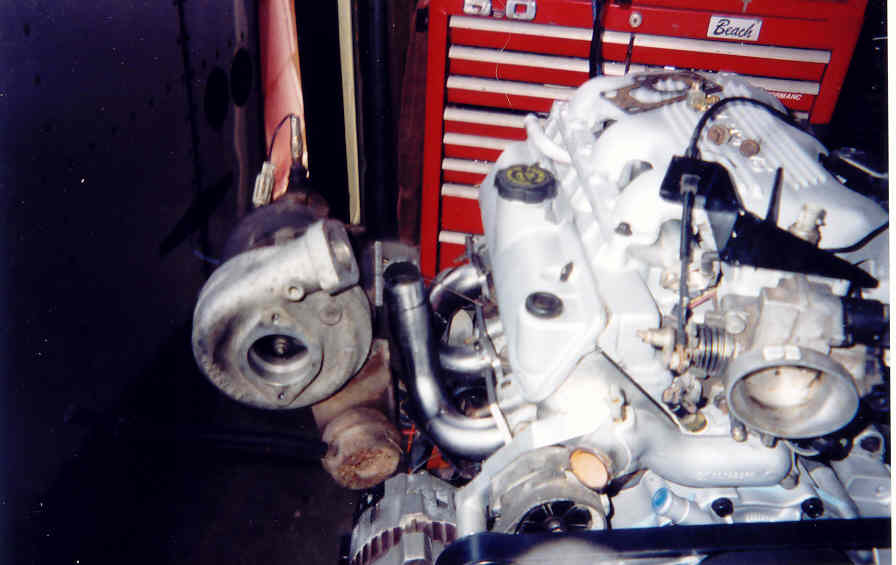

At this point, I figure I might be better off doing either a 3.4l Camaro block and putting in a HT Crate engine cam, or getting a RWD 2.8 or 3.1l block and putting my crank and pistons in it.

The Pros and cons for each, I figure are:

The 3.4l swap has been widely done, is proven, and would be easy. It should work fine with the 7730 ECU and wiring harness that I already have. Engine mounts are no problem. On the downside, it will be hard to find a cheap 3.4l engine that has low mileage and doesn't need a rebuild. It will also probably have less power than the hybrid with the post 2k upper.

The Hybrid option would give me the performance benefits of the post 2k upper engine. That would eliminate the mount problem. Assuming that I can find a block that will take my pistons, I already have the parts for the lower since they probably aren't very worn at 27K. Also, the heads should be in fantastic condition at this low mileage. On the downside, the machine shop work on the lower might cost a lot of money.

1) So, do you guys see any flaws in my logic?

2) If so, what are they?

3) Which option would you guys recommend (with a third option of continuing on with the 3100 fwd block)?

4) Does anyone have a ballpark idea for what it would cost to dissasemble a short block, have it hot tanked, tested for cracks, and then have them remove crank, pistons, and pieces from my engine to transplant into the rwd block and have it re-cammed? I'm assuming that I can reuse most of my 3100 parts. If it sounds like it will cost a lot, I might do better to sell or part out the 3100 and move on to a 3.4L.

Anyway, I'm too far into this project with the tranny, transfer case, and ECU to switch engine types, so I'm going to stick with the 660. In retrospect, it may have been better to start with the 3.4l RWD engine or use a 4.3.

Thanks in advance!

I have, in my posession, a 2002 Buick Century engine that ony has 27K on it. Unfortunately, the oil pan will not work in my 4x4s configuration. When I purchased the engine, I mistakenly thought that I could just use a pan off of one of the older engines with a little modification. This doesn't appear to be the case, so I"m stuck with trying to fabricate an oil pan which is out of my league. Also, the stock pan is aluminum which makes cutting and combining two pans unlikely without some serious money. I don't even know if they made 660 4x4 pans in aluminum. Anyway, that is going to cost some money to overcome since I'll have to farm it out.

Another problem is that the motor mounts on the engine are fairly expensive since there aren't really any RWD mounts out there for the drivers side. I'm looking at about $200 for a set of unwelded mounts, plus the cost of having them welded together (I suck at welding and wouldn't want to assemble the mounts. )

So, at this point, I figure that I'm out about $500 or so at least on top of whatever other problems come up.

At this point, I figure I might be better off doing either a 3.4l Camaro block and putting in a HT Crate engine cam, or getting a RWD 2.8 or 3.1l block and putting my crank and pistons in it.

The Pros and cons for each, I figure are:

The 3.4l swap has been widely done, is proven, and would be easy. It should work fine with the 7730 ECU and wiring harness that I already have. Engine mounts are no problem. On the downside, it will be hard to find a cheap 3.4l engine that has low mileage and doesn't need a rebuild. It will also probably have less power than the hybrid with the post 2k upper.

The Hybrid option would give me the performance benefits of the post 2k upper engine. That would eliminate the mount problem. Assuming that I can find a block that will take my pistons, I already have the parts for the lower since they probably aren't very worn at 27K. Also, the heads should be in fantastic condition at this low mileage. On the downside, the machine shop work on the lower might cost a lot of money.

1) So, do you guys see any flaws in my logic?

2) If so, what are they?

3) Which option would you guys recommend (with a third option of continuing on with the 3100 fwd block)?

4) Does anyone have a ballpark idea for what it would cost to dissasemble a short block, have it hot tanked, tested for cracks, and then have them remove crank, pistons, and pieces from my engine to transplant into the rwd block and have it re-cammed? I'm assuming that I can reuse most of my 3100 parts. If it sounds like it will cost a lot, I might do better to sell or part out the 3100 and move on to a 3.4L.

Anyway, I'm too far into this project with the tranny, transfer case, and ECU to switch engine types, so I'm going to stick with the 660. In retrospect, it may have been better to start with the 3.4l RWD engine or use a 4.3.

Thanks in advance!

Plus, I'll keep an eye out in the yards for a 3.4l block to keep around and tinker with...

Plus, I'll keep an eye out in the yards for a 3.4l block to keep around and tinker with...

Comment