Sorry for no intro but between my job, and this project I'm short on time.

Long story short a good friend of mine's dad was just diagnosed with cancer, doesn't look great hence my urgency. Years ago the dad taught me how to build an engine, and him and my friend have done everything on cars, except that. So I'm going to make that happen one way or another.

Due to time constraints we settled on a 2.8 because we have one (40k miles). At this point we just want to build an engine. We do plan on doing turbos down the line, so I'm donating an extra Haltech to the cause and an e-throttle. I have tried to do as much research as I can but I'm still left with a few questions, ones I'm sure have been asked a thousand times before, but I just haven't found the answers. I will keep looking and will cross post this to v6z24.com. We're not chasing big numbers, just want to build a memory, and do a few neat things to it when it goes in the car, (88 Sunbird).

My first thought was making the engine breathe better by doing the 3100/3400 head/intake swap, but as I understand it this will send compression through the roof?

I keep seeing references to not crossing the 7psi threshold when boosting. I'm curious how that number came about. Is there a weak link to the engine that limits it? Tuning issue? Oiling?

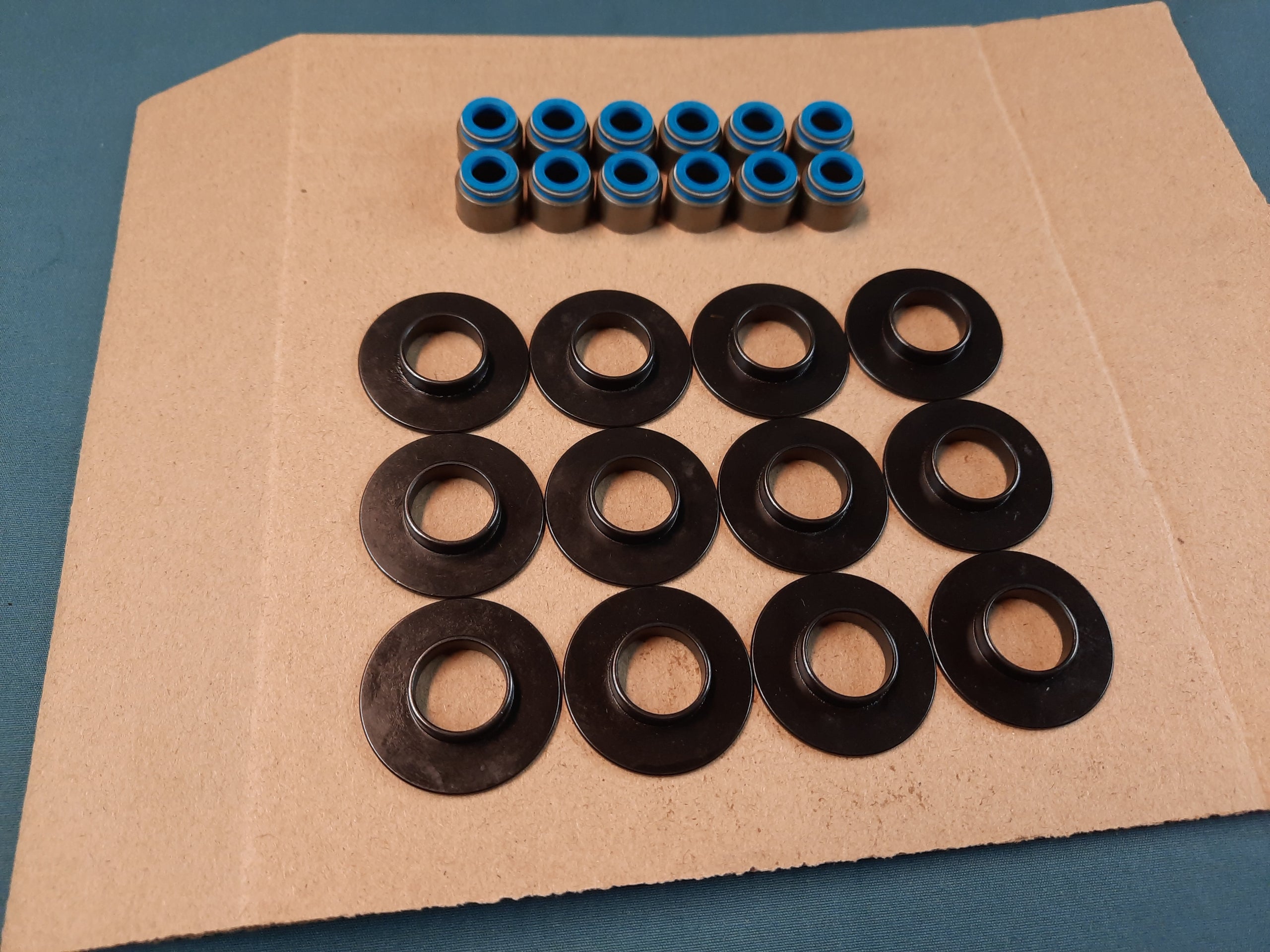

I only work on Japanese engines, so I don't know which is the best route for a rebuild kit. New bearings, rings, etc. Open to the idea of a different cam and springs, but again, we're more concerned with making the memory than the engine itself. So if I can't source that bit in time we'll work with what we have.

Thanks for your time, and apologies for being blunt, and if this is in the wrong spot I truly am sorry.

This Guy

Long story short a good friend of mine's dad was just diagnosed with cancer, doesn't look great hence my urgency. Years ago the dad taught me how to build an engine, and him and my friend have done everything on cars, except that. So I'm going to make that happen one way or another.

Due to time constraints we settled on a 2.8 because we have one (40k miles). At this point we just want to build an engine. We do plan on doing turbos down the line, so I'm donating an extra Haltech to the cause and an e-throttle. I have tried to do as much research as I can but I'm still left with a few questions, ones I'm sure have been asked a thousand times before, but I just haven't found the answers. I will keep looking and will cross post this to v6z24.com. We're not chasing big numbers, just want to build a memory, and do a few neat things to it when it goes in the car, (88 Sunbird).

My first thought was making the engine breathe better by doing the 3100/3400 head/intake swap, but as I understand it this will send compression through the roof?

I keep seeing references to not crossing the 7psi threshold when boosting. I'm curious how that number came about. Is there a weak link to the engine that limits it? Tuning issue? Oiling?

I only work on Japanese engines, so I don't know which is the best route for a rebuild kit. New bearings, rings, etc. Open to the idea of a different cam and springs, but again, we're more concerned with making the memory than the engine itself. So if I can't source that bit in time we'll work with what we have.

Thanks for your time, and apologies for being blunt, and if this is in the wrong spot I truly am sorry.

This Guy

Comment