Originally posted by 1988GTU

View Post

Announcement

Collapse

No announcement yet.

MG Midget

Collapse

X

-

The S10 clutch we used started slipping badly last week. Likely it just needed a longer break-in period. However, instead of just fixing the problem, we improved the car further . On the weekend we traded engines with my Fiero. So now it has a big N/A cam (which dynoed at 256whp in my Fiero) and also an 8 lb Fidanza flywheel with the Clutchnet 6-puck I ran in my Firebird last year.

. On the weekend we traded engines with my Fiero. So now it has a big N/A cam (which dynoed at 256whp in my Fiero) and also an 8 lb Fidanza flywheel with the Clutchnet 6-puck I ran in my Firebird last year.

Trans tunnel was modified a bit for the new shifter location and it got a Cosmo racing short shifter.

Oil filter relocation kit installed. Still a tight fit with the steering linkage but better than using a dented oil filter .

.

'89 Firebird, 3500 Turbo, T56, 9-bolt/4.11

'89 Firebird, 3500 Turbo, T56, 9-bolt/4.11

'86 Fiero, 3500, 4-speed

Comment

-

Looks good, but I would have run the filter vertical for cleaner oil changes.

Also my Rangers filter is horizontal like that and it tends to drain back into into the engine causing dry starts so I've gotten a 90* adapter from a 5.0 in the yard, I just need to figure up the banjo bolt since it wasn't long enough to work.

I'm guessing the pic with the steering linkage I'd upside down, so that would mean yours would have to go uphill to drain back.

Sent from my HTC One_M8 using Tapatalk-60v6's 2nd Jon M.

91 Black Lumina Z34-5 speed

92 Black Lumina Z34 5 speed (getting there, slowly... follow the progress here)

94 Red Ford Ranger 2WD-5 speed

Originally posted by Jay LenoTires are cheap clutches...

Comment

-

Went to the 384' track today and it ran well.

Idle is way nastier with this cam

Final run/best time of the day

Pretty consistently 1.8 sec. 60-fts. I'm pretty sure they're a bit high because the 1-2 shift happens before the 60-ft mark.

Best run was 5.596 @ 72.34 MPH. 5.096 330 ft. time.

This was all on street tires since there's no driveshaft safety loop installed yet.Last edited by caffeine; 06-23-2014, 12:34 AM.'89 Firebird, 3500 Turbo, T56, 9-bolt/4.11

'86 Fiero, 3500, 4-speed

Comment

-

Sorry for my ignorance, but what is the function of a "slash cut"?Originally posted by Superdave View PostAwesome build but I see 1 major issue...

if you place the o2 after or next to the slash cuts you get a false lean condition on the o2 sensor. you need to move the o2's further up in the stream or the slashcuts further down.

Comment

-

The idea is you can use exhaust flow to develop a vacuum in the crankcase at higher rpm. This in turn aids oil return and piston ring sealing. Pulling a vacuum in the crankcase at WOT has been dyno proven to increase hp.'89 Firebird, 3500 Turbo, T56, 9-bolt/4.11

'86 Fiero, 3500, 4-speed

Comment

-

And it keeps the water vapor out of the oil

Every time you shut your engine off, it's the reverse effect of a cold soda sitting outside and condensation builds. So, when it warms back up it turns from fluid water back to vapor and a vacuum source will evacuate it. We have done a lot of builds, and always retain crankcase vacuum, it's just better all the way around (not just power).

Comment

-

Originally posted by caffeine View PostThe idea is you can use exhaust flow to develop a vacuum in the crankcase at higher rpm. This in turn aids oil return and piston ring sealing. Pulling a vacuum in the crankcase at WOT has been dyno proven to increase hp.Interesting! So what is the optimal cut shape, angle to exhaust flow, depth, and pipe diameter to get the best venturi effect without creating an exhaust flow restriction?Originally posted by ForcedFirebird View PostAnd it keeps the water vapor out of the oil

Comment

-

45 degrees, 45 degrees, center of the pipe, about 1/2" to 3/4" pipe with a check valve.

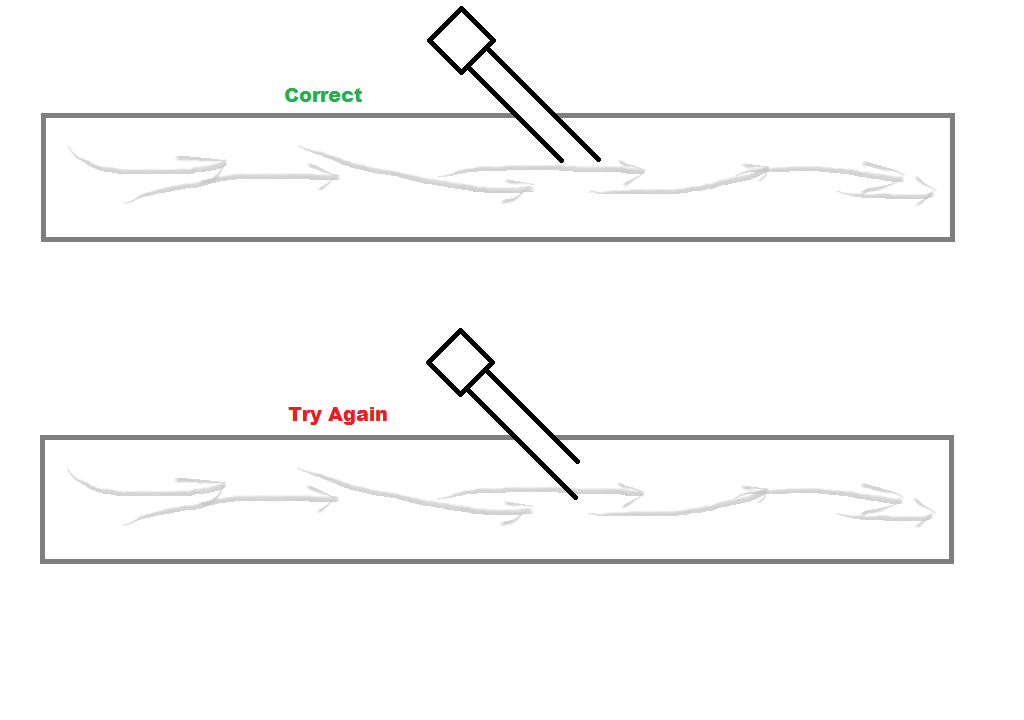

There is debate about the tip angle to the pipe, I did mine like the top and it worked for sure.

the kits from Summit work well.

Comment

Comment