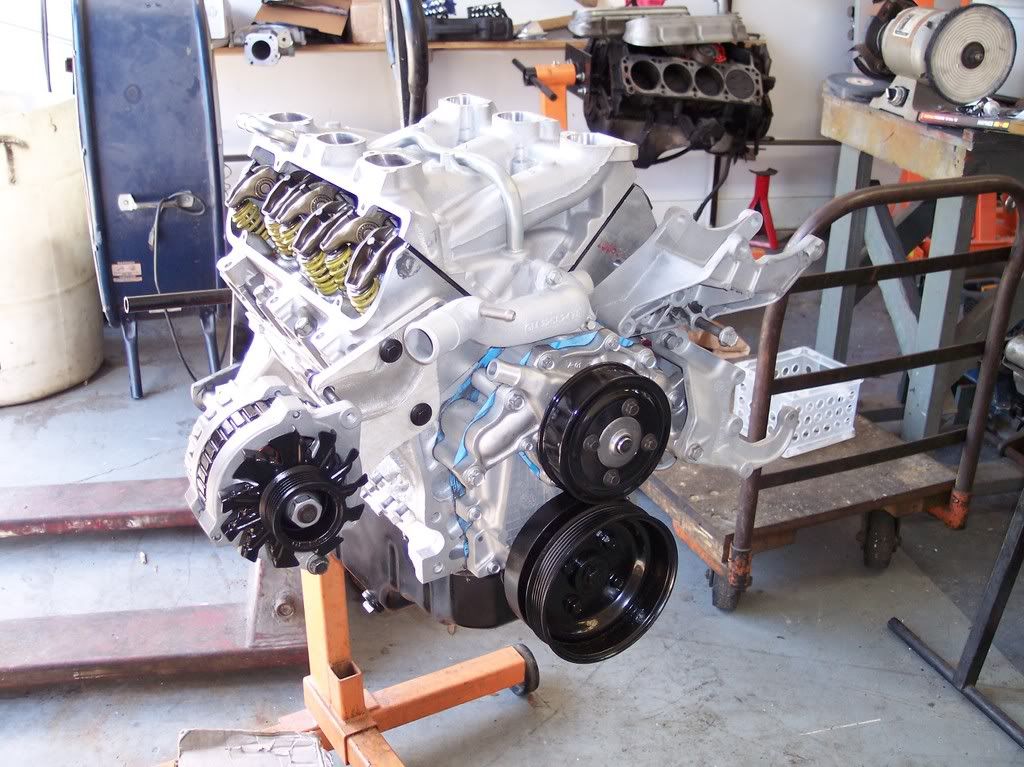

Yeah, I haven't had the justification to rebuild any other engine either. Maybe after I grenade this 3.4L.

I should learn some other things first anyway, maybe do an OBDII conversion and tune a few more horses into my current setup.

I should learn some other things first anyway, maybe do an OBDII conversion and tune a few more horses into my current setup.

Comment