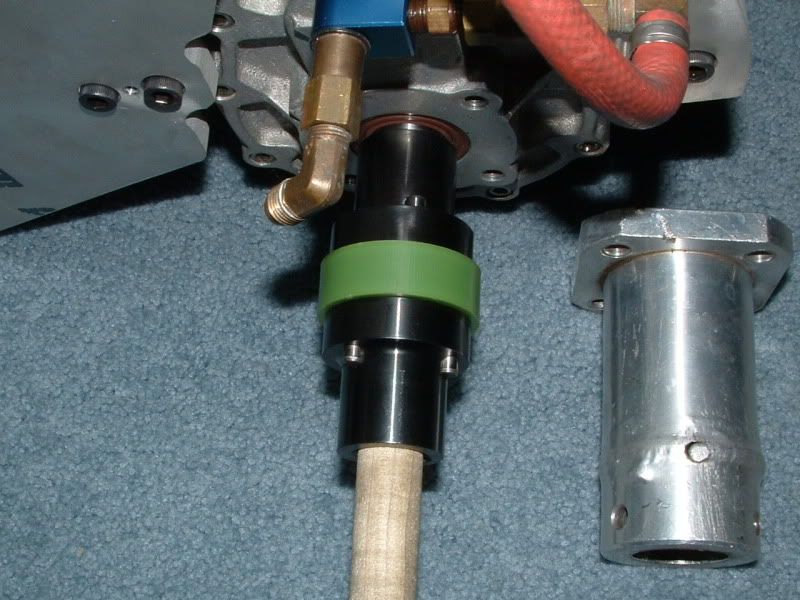

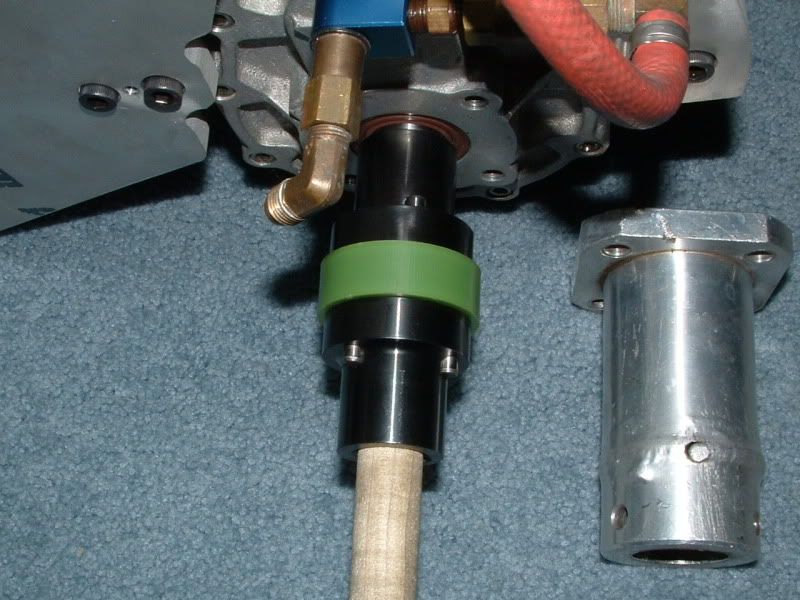

I have been playing around with superchargers for the FWD vehicles for a little while now (the pic of the Vortech V-5 unit in the green grand am is mine). I still have another supercharger setup that I am working on that should have been done by now if it wasn't for the machine shop being behind on production runs. What I am working on is a redesign of the RSM kit to fix their drive shaft issues, which consists of a redesigned drive shaft assembly that uses a Eaton composite coupling, and a 6204 bearing rated to 20,000 RPM. The setup also allows the use of Vortech pulleys, so boost levels on the V-9 supercharger can be changed rather easily. I also have mounts for the both the grand am/N-body and W-body for the Vortech V-9 headunit.

A few pics of the mock up pics over the years:

Some tips that I have found that help:

1. Start with mounting the supercharger as this will effect the length of the drive shaft and pulley alignment.

2. Use wooden dowel rods, card board, PVC pipe and thin gauge aluminum that can be cut with tin snips to help with mockup of the drive shaft.

A few pics of the mock up pics over the years:

Some tips that I have found that help:

1. Start with mounting the supercharger as this will effect the length of the drive shaft and pulley alignment.

2. Use wooden dowel rods, card board, PVC pipe and thin gauge aluminum that can be cut with tin snips to help with mockup of the drive shaft.

Comment