Hello was debating on an interesting project here, looking for some help on a couple questions.

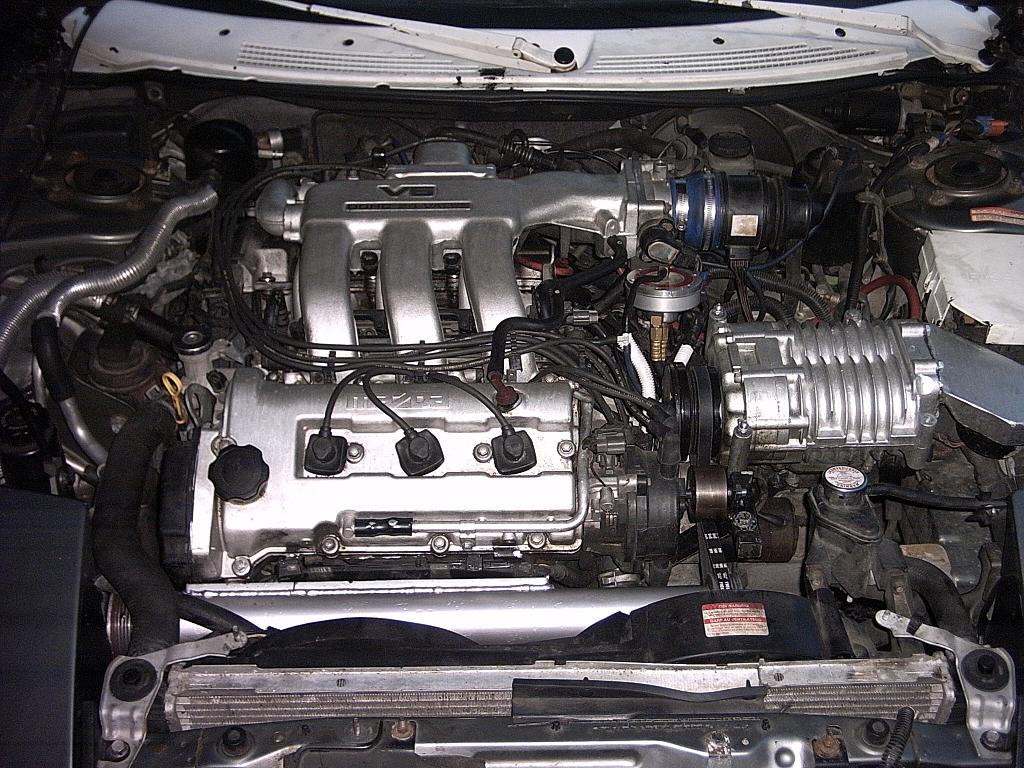

Also, this isn't a debate on turbo or SC, i,m determined to adapt a SC. And i know its been disscussed but I'm trying to basically replicate the m62 kit for the grand am, it just seems to be an extended shaft with a mount. The castings for the intake aren't an issue.

Using an m90 SC.

Looking to extend the shaft about 15", i found a write up on how someone extended the shaft of one using a solid rod with threading.

The original SC shaft was modified, removed the pully and threaded about 4" down (the snout was also modified). Then another steel rod/shaft was threaded inside and the two were screwed together the opposite direction of how they would spin to ensure they wouldn't loosen. And there were mounts made to keep everything straight. Does this even sound safe to you guys? I have a friend with serious equipment, just seeing if its safe before beginning.

Also building the extra bearing mounts to hold the extended shaft in place seems tricky. Where can i find bearings that would be safe at those speeds? Could i simply use another snout from an m90 for the mount, or at least parts of the snout? I have multiple SC'S here just collecting dust.

Looking for a little help from you guys before starting something crazy, which hopefully will work.

Also, this isn't a debate on turbo or SC, i,m determined to adapt a SC. And i know its been disscussed but I'm trying to basically replicate the m62 kit for the grand am, it just seems to be an extended shaft with a mount. The castings for the intake aren't an issue.

Using an m90 SC.

Looking to extend the shaft about 15", i found a write up on how someone extended the shaft of one using a solid rod with threading.

The original SC shaft was modified, removed the pully and threaded about 4" down (the snout was also modified). Then another steel rod/shaft was threaded inside and the two were screwed together the opposite direction of how they would spin to ensure they wouldn't loosen. And there were mounts made to keep everything straight. Does this even sound safe to you guys? I have a friend with serious equipment, just seeing if its safe before beginning.

Also building the extra bearing mounts to hold the extended shaft in place seems tricky. Where can i find bearings that would be safe at those speeds? Could i simply use another snout from an m90 for the mount, or at least parts of the snout? I have multiple SC'S here just collecting dust.

Looking for a little help from you guys before starting something crazy, which hopefully will work.

Comment