Hello,

I just wanted to share my build with some true enthusiasts.

this is my truck,

My father and I rebuilt the engine 2 years ago.

It's the original 2.8 block, bored/stroked to 3.2

heads are off a 2.8fi Camaro

3/4 cam lifter kit

Edelbrock intake w/ 4barrel adapter, 600cfm holley

Index ground 3.1 Crank

Line bored crank internals

Blue printed

bored/honed to 40 thou over

9.5 compression

hedman headers

2.25" true dual exhaust

I drove it like this for a year and it was definitely a lot peppier then the tired old motor that I was used to.

I found a member on s10forum who had found a fageol blower and was fortunate enough to buy it from him.

it is designed to run the original rochester 2 barrel but we thought it would be fun to run the holley 4 barrel I currently have so my dad and I set about making up an adapter plate,

When I first purchased the supercharger the owner suggested swapping from the v-belt set up to a serpentine one. The kit was incomplete and was missing the crank pulley which was a very key part of the v belt set up. So we opted to do the serpentine swap knowing I could get a serp pulley for the supercharger easily. This turned out to be a lot more work then I had anticipated. I ended up having to change the water pump, timing cover and oil pan.

started to tear it down,

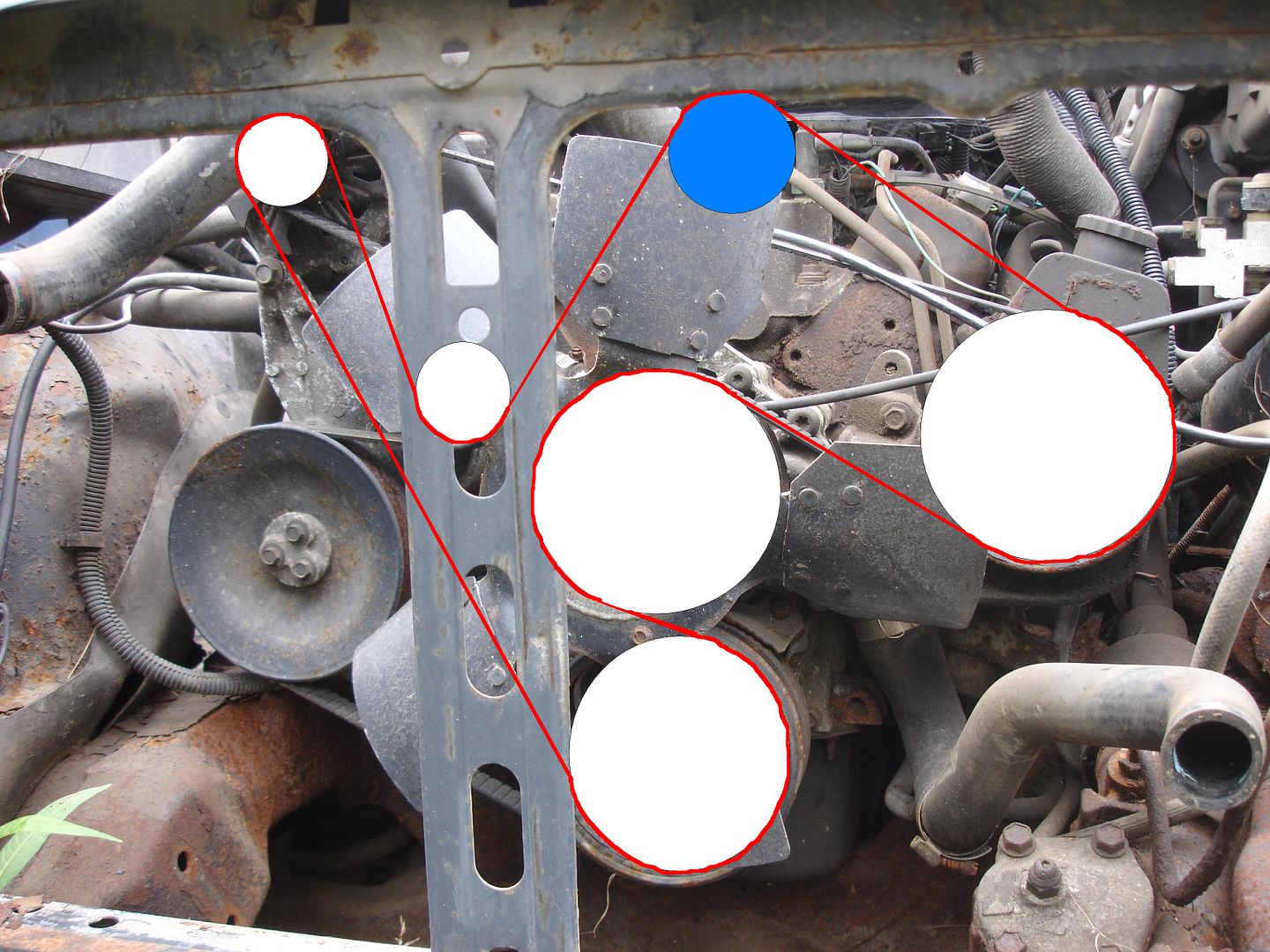

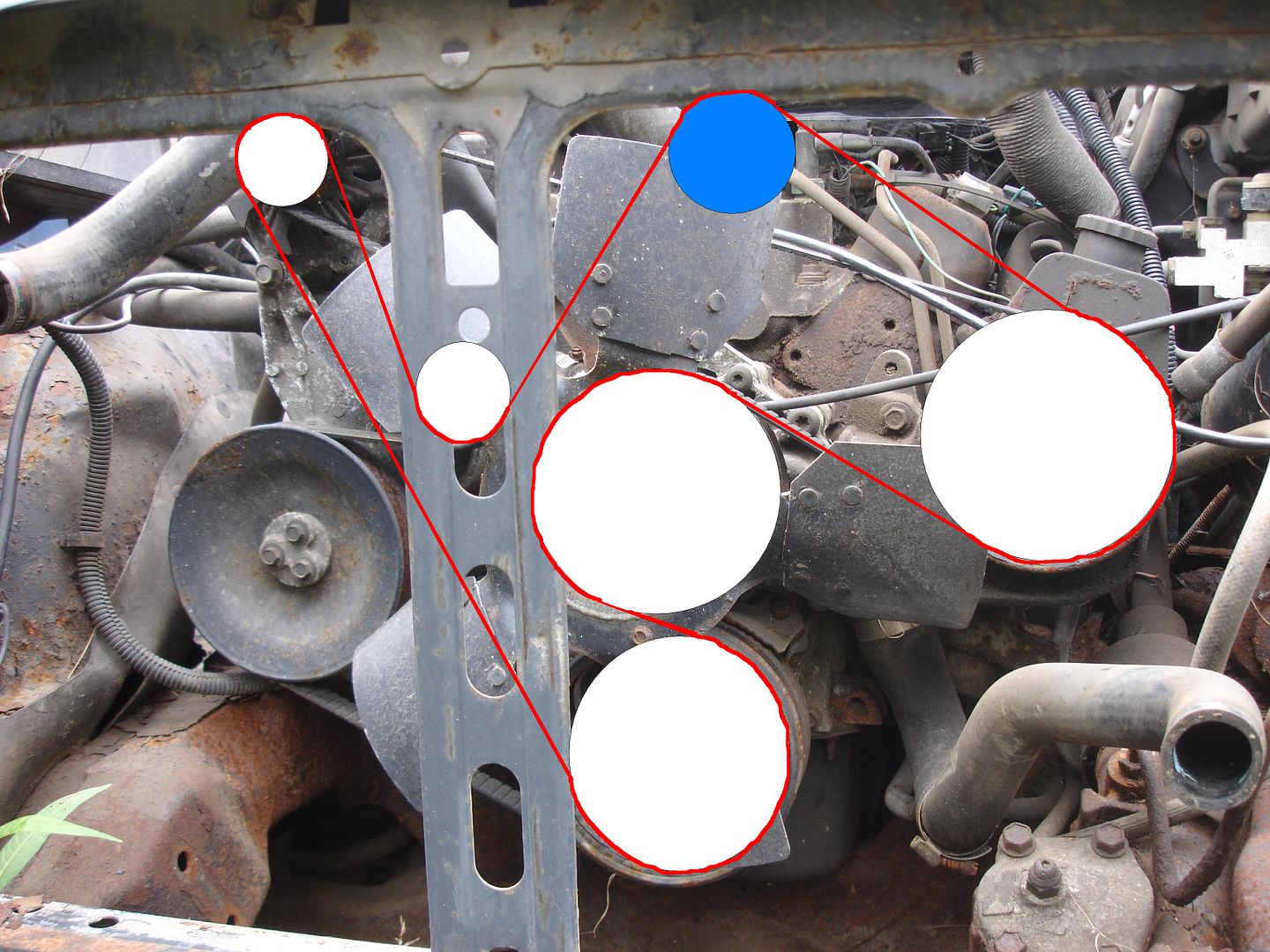

trying to decide on serp routing,

motor pulled to change the oil pan, dad in the background

turned out vortech makes a direct bolt on serp pulley,

some mock up,

had to make up an idler pulley bracket so the belt would have more wrap on the supercharger,

as a side project I picked up a hurst quick shifter. If anyone has ever driven an s10 with the t5 you know how long the shifts are with the stock stick.

turned out though the only gain that could be had with the hurst shifter was putting on a shorter shifter arm,

The pins were identical in length so there was no real gain in it's original form.

so we made up a custom base and moved the pin/shaft down further to actually give a quicker throw,

the last thing we did was slot the shaft so it doesn't feel all lose and cheap when bolt to the shifter stick,

it's in a nice comfortable position still but it 50% shorter then oe

had the new pieces anodized,

spent a good while messing around and not really moving forward to much, Finally we started to get everything bolted down and back together,

oil lines ran,

my dad made up some caste nuts so we could safety wire the bolts inside the 4 barrel adapter,

back in,

02 sensor,

new alt,

figuring belt size,

finally after a couple of different belts we got it running,

It was late in the year and the snow was only a couple weeks away. So I just enjoyed it. Right now it's running just over 4lbs. We are going to make a slightly smaller pulley to get it to around 6/7. Anymore then that and I'll really be pushing my luck with the compression as high as it is on stock internals.

I just wanted to share my build with some true enthusiasts.

this is my truck,

My father and I rebuilt the engine 2 years ago.

It's the original 2.8 block, bored/stroked to 3.2

heads are off a 2.8fi Camaro

3/4 cam lifter kit

Edelbrock intake w/ 4barrel adapter, 600cfm holley

Index ground 3.1 Crank

Line bored crank internals

Blue printed

bored/honed to 40 thou over

9.5 compression

hedman headers

2.25" true dual exhaust

I drove it like this for a year and it was definitely a lot peppier then the tired old motor that I was used to.

I found a member on s10forum who had found a fageol blower and was fortunate enough to buy it from him.

it is designed to run the original rochester 2 barrel but we thought it would be fun to run the holley 4 barrel I currently have so my dad and I set about making up an adapter plate,

When I first purchased the supercharger the owner suggested swapping from the v-belt set up to a serpentine one. The kit was incomplete and was missing the crank pulley which was a very key part of the v belt set up. So we opted to do the serpentine swap knowing I could get a serp pulley for the supercharger easily. This turned out to be a lot more work then I had anticipated. I ended up having to change the water pump, timing cover and oil pan.

started to tear it down,

trying to decide on serp routing,

motor pulled to change the oil pan, dad in the background

turned out vortech makes a direct bolt on serp pulley,

some mock up,

had to make up an idler pulley bracket so the belt would have more wrap on the supercharger,

as a side project I picked up a hurst quick shifter. If anyone has ever driven an s10 with the t5 you know how long the shifts are with the stock stick.

turned out though the only gain that could be had with the hurst shifter was putting on a shorter shifter arm,

The pins were identical in length so there was no real gain in it's original form.

so we made up a custom base and moved the pin/shaft down further to actually give a quicker throw,

the last thing we did was slot the shaft so it doesn't feel all lose and cheap when bolt to the shifter stick,

it's in a nice comfortable position still but it 50% shorter then oe

had the new pieces anodized,

spent a good while messing around and not really moving forward to much, Finally we started to get everything bolted down and back together,

oil lines ran,

my dad made up some caste nuts so we could safety wire the bolts inside the 4 barrel adapter,

back in,

02 sensor,

new alt,

figuring belt size,

finally after a couple of different belts we got it running,

It was late in the year and the snow was only a couple weeks away. So I just enjoyed it. Right now it's running just over 4lbs. We are going to make a slightly smaller pulley to get it to around 6/7. Anymore then that and I'll really be pushing my luck with the compression as high as it is on stock internals.

Comment