I haven't ever dropped the oil pan for the 3100 96 GP.

And after looking around it seems it is going to be a tricky procedure.

Can anyone give me some advice before I dive in?

It looks like I would need to raise the engine some?

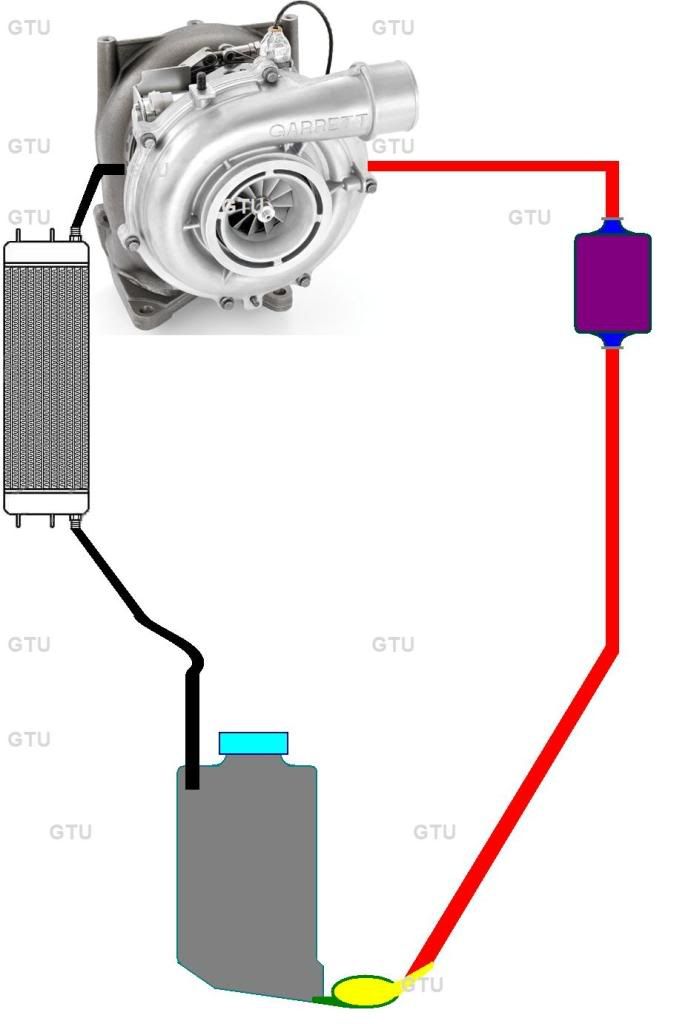

I have considered getting an oil scavenge pump. If removing the oil pan is going to be extensive, I just might get an oil cooler and scavenge pump. Pump it into the drain plug.

Anyone have any tricks that might make tapping the oil pan easier? Could one drill out a hole and tap a threaded/barbed fitting with the oil pan still on the block? Then flush the oil pan from above to remove any aluminum shreds?

Thanks

And after looking around it seems it is going to be a tricky procedure.

Can anyone give me some advice before I dive in?

It looks like I would need to raise the engine some?

I have considered getting an oil scavenge pump. If removing the oil pan is going to be extensive, I just might get an oil cooler and scavenge pump. Pump it into the drain plug.

Anyone have any tricks that might make tapping the oil pan easier? Could one drill out a hole and tap a threaded/barbed fitting with the oil pan still on the block? Then flush the oil pan from above to remove any aluminum shreds?

Thanks

Comment