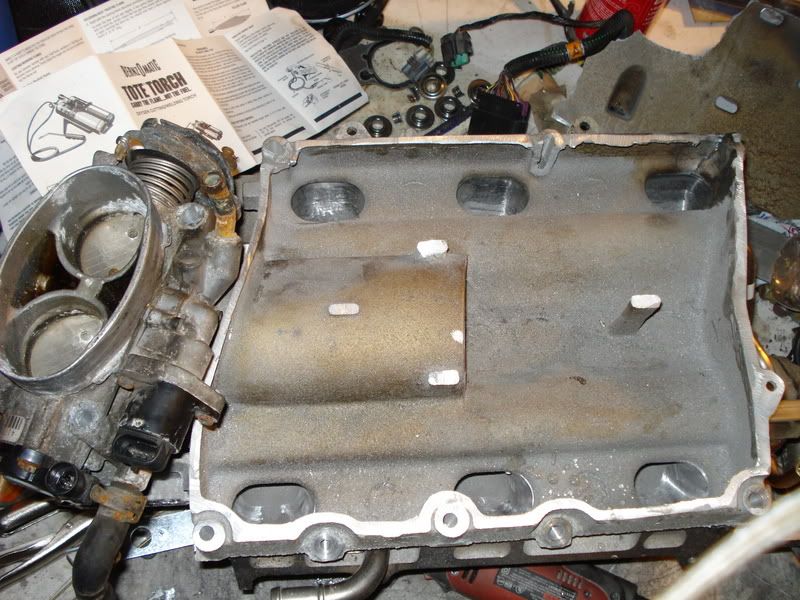

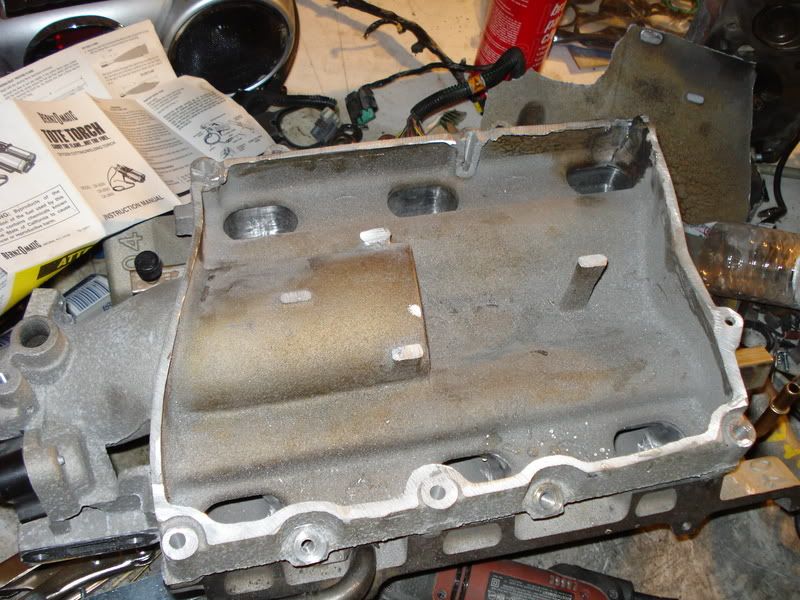

Looking at the design of the 3500 plenum, Im concerned about spraying a wet shot through it. With the TB neck extending all of the way to the center of the plenum, it is obviously not the best design for nitrous. The nitrous/fuel mixture is going to make a 180* turn to get back to the front two intake ports and may end up puddling in the process.

Right now Ive got a single stage wet setup with my 3400 plenum and have successfully sprayed a 75 shot numerous times. My new motor is going to have a 3500 plenum though, and a second stage of dry nitrous. The bottom end is built (scat H beams and forged 11:1 pistons) and is more than capable of handling 100+ nitrous horsepower. For the larger of the two shots, Id prefer wet but the plenum design has me very concerned. Im not going with a DP setup because of cost, and its overkill for anything under a 200hp shot.

Would you guys chance it with the wet shot, or go with two dry stages? Ive got enough injector and pump to handle quite a bit of fuel (pump rewire and 36#) Opinions?

Right now Ive got a single stage wet setup with my 3400 plenum and have successfully sprayed a 75 shot numerous times. My new motor is going to have a 3500 plenum though, and a second stage of dry nitrous. The bottom end is built (scat H beams and forged 11:1 pistons) and is more than capable of handling 100+ nitrous horsepower. For the larger of the two shots, Id prefer wet but the plenum design has me very concerned. Im not going with a DP setup because of cost, and its overkill for anything under a 200hp shot.

Would you guys chance it with the wet shot, or go with two dry stages? Ive got enough injector and pump to handle quite a bit of fuel (pump rewire and 36#) Opinions?

Comment