Working on a Physics formula involving heat transfer through iron and aluminum from coolant to intake air charge.

I am building the formula to get a very precise charting of temperature differences from the IAT Sensor versus the Intake Valve.

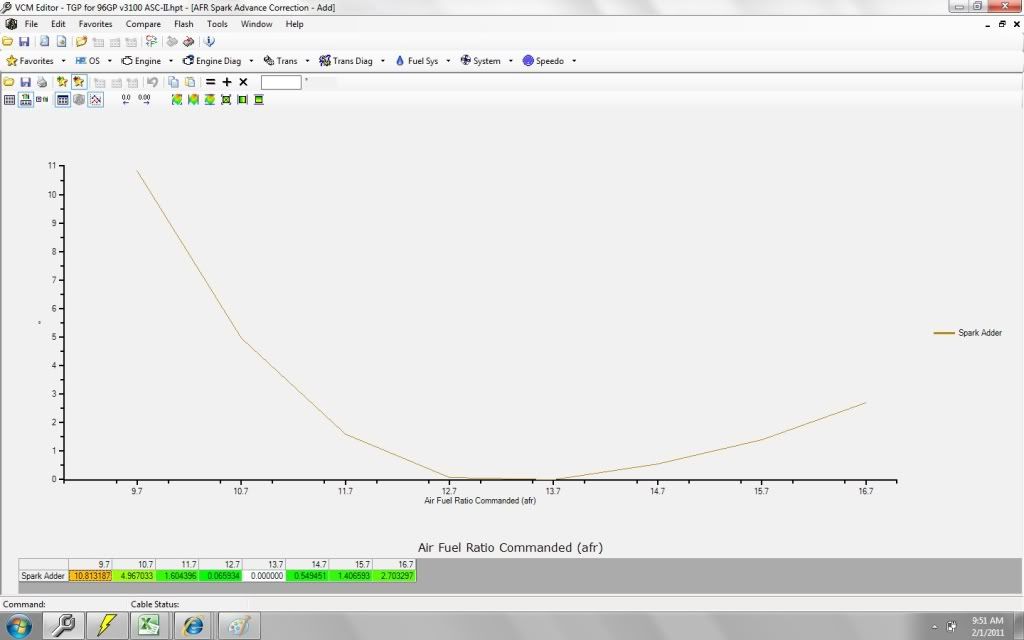

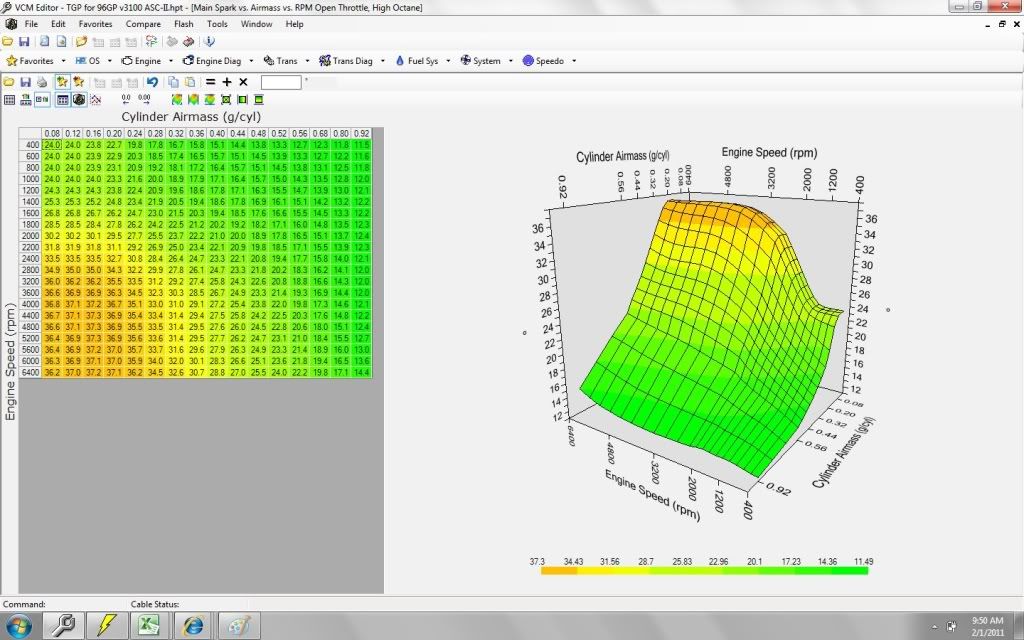

I will share my results when finished, including some really neat spark maps resulting from such formulas as well.

Sooo, any know the volume of the Plenum, Lower Intake Manifold and the intake bowl in the heads? Please help, I am desperate and I REALLY don't want to take my engine apart to get these figures!!!

I am building the formula to get a very precise charting of temperature differences from the IAT Sensor versus the Intake Valve.

I will share my results when finished, including some really neat spark maps resulting from such formulas as well.

Sooo, any know the volume of the Plenum, Lower Intake Manifold and the intake bowl in the heads? Please help, I am desperate and I REALLY don't want to take my engine apart to get these figures!!!

Comment