the project engine.. a 95 GTP ..

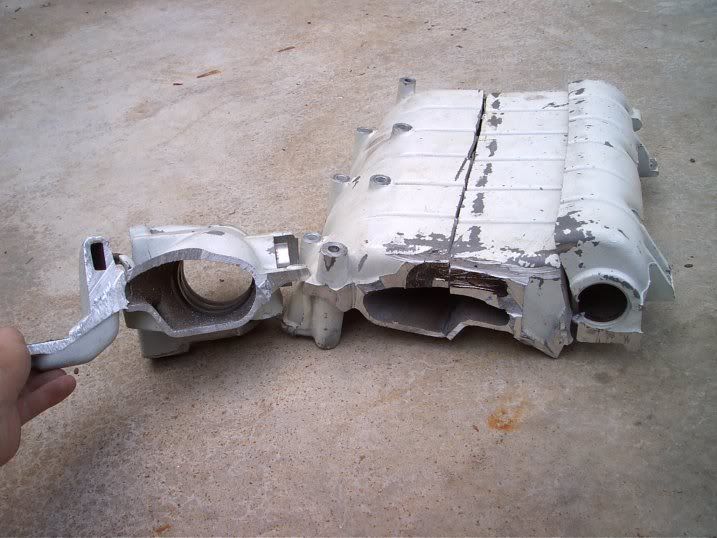

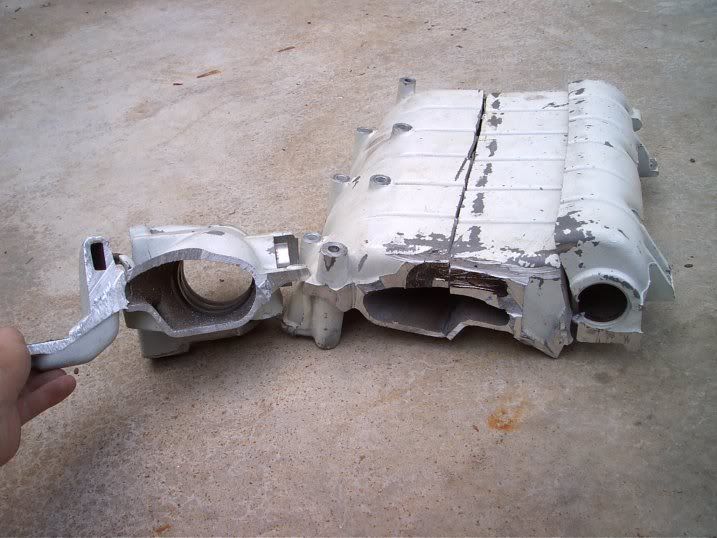

sawsall and die grinder with cutoff wheel made pretty quick work of the cast intake manifold

here you can see the two biggest restrictions..

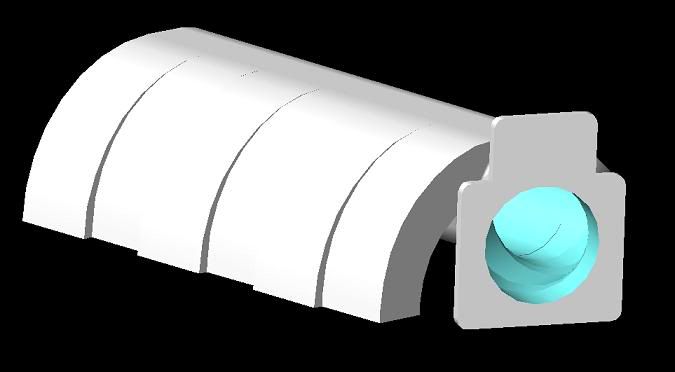

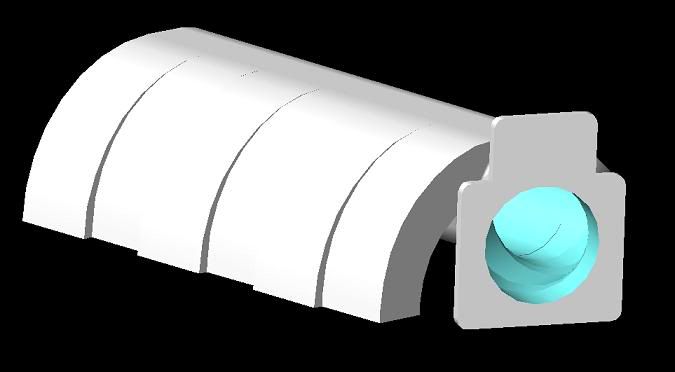

so the plan next was to weld a 3" tube to the ends of the runners after doing some porting to them to improve flow and use the bolt on throttle body from a 96

after cutting all the pieces and brazing them in place I took the intake to Coffee Hill welding.. they did an awesome job welding up all up for about 50$

I then ground down the welds and used some epoxy to fill in any dips

if you can fit your hand through a 3" hole theny ou can fist this intake to the back

after sanding with 80 grit on a mouse palm sander.. adding 3 coats of primer and one of top coat..

now back to tuning

sawsall and die grinder with cutoff wheel made pretty quick work of the cast intake manifold

here you can see the two biggest restrictions..

so the plan next was to weld a 3" tube to the ends of the runners after doing some porting to them to improve flow and use the bolt on throttle body from a 96

after cutting all the pieces and brazing them in place I took the intake to Coffee Hill welding.. they did an awesome job welding up all up for about 50$

I then ground down the welds and used some epoxy to fill in any dips

if you can fit your hand through a 3" hole theny ou can fist this intake to the back

after sanding with 80 grit on a mouse palm sander.. adding 3 coats of primer and one of top coat..

now back to tuning

Comment