This applies to the pushrod motors just as well, but Im getting some dirty thaughts about using it in my 3.4 DOHC SC.

I was looking at the new 3500 as a possible donor for more modern and stronger bottom end parts to add to my 3.4 DOHC SC project. I was alittle dissapointed to find that the stroke was 84 mm just like every other 3.1 and 3.4 out there. (I was hoping for some sort of a stroker) But then I stumbled on the fact that the crankshaft IS actually VERY different then that of a 3400/3100.

There are two cranks for the 3500's. One is a cast iron crank with larger rod journals, and the other is a FORGED STEEL crank also with 2.25" rod journals. Even bigger journals then the SBC! It seems like they made a high performance, toss it in crank for us. Well almost it seems. The main journals are the same size as the 3400 as far as I can tell (and the 3.4 DOHC for that matter) so it might just fit nicley. However the reluctor seems to have changed to a 24X reference unit, so it isn't really compatible with our ignition systems. Perhaps something that can be easily retrofitted might do the trick. (Steel welds quite well) But heres some info on the unit I found on beretta.net

CRANKSHAFT

A large-pin iron crankshaft is stiffer than a standard crank. The stiffness added by this type of crank improves the stiffness of the engine, resulting in a quieter, smoother engine. This crank is used in the 2005 Uplander, Relay and SV6.

To further reduce NVH and deliver even more refined performance, the Terraza, G6 and Malibu utilize a large-pin crankshaft made from steel.

Critical specs for the 3500

Connecting Rod Journal Diameter 2.248-2.249 in

Connecting Rod Journal Width 0.863-0.869 in

Crankshaft Main Bearing Journal Width 0.941-0.949 in

Crankshaft Main Journal Diameter 2.6473-2.6483 in

Respective specs for the 3400

Connecting Rod Journal Diameter 1.9987-1.9994 in

Crankshaft Main Journal Diameter 2.6473-2.6483 in

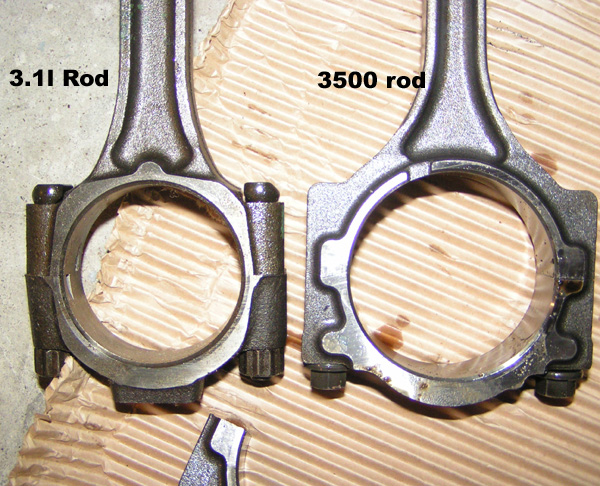

I'm having a hard time finding the journal widths for the 3400... but since the 3500 crank needs different rods it doesn't matter anymore. But hey, its was the only part of my engine I have not found a stronger replacment for so it's worth consideration.

I was looking at the new 3500 as a possible donor for more modern and stronger bottom end parts to add to my 3.4 DOHC SC project. I was alittle dissapointed to find that the stroke was 84 mm just like every other 3.1 and 3.4 out there. (I was hoping for some sort of a stroker) But then I stumbled on the fact that the crankshaft IS actually VERY different then that of a 3400/3100.

There are two cranks for the 3500's. One is a cast iron crank with larger rod journals, and the other is a FORGED STEEL crank also with 2.25" rod journals. Even bigger journals then the SBC! It seems like they made a high performance, toss it in crank for us. Well almost it seems. The main journals are the same size as the 3400 as far as I can tell (and the 3.4 DOHC for that matter) so it might just fit nicley. However the reluctor seems to have changed to a 24X reference unit, so it isn't really compatible with our ignition systems. Perhaps something that can be easily retrofitted might do the trick. (Steel welds quite well) But heres some info on the unit I found on beretta.net

CRANKSHAFT

A large-pin iron crankshaft is stiffer than a standard crank. The stiffness added by this type of crank improves the stiffness of the engine, resulting in a quieter, smoother engine. This crank is used in the 2005 Uplander, Relay and SV6.

To further reduce NVH and deliver even more refined performance, the Terraza, G6 and Malibu utilize a large-pin crankshaft made from steel.

Critical specs for the 3500

Connecting Rod Journal Diameter 2.248-2.249 in

Connecting Rod Journal Width 0.863-0.869 in

Crankshaft Main Bearing Journal Width 0.941-0.949 in

Crankshaft Main Journal Diameter 2.6473-2.6483 in

Respective specs for the 3400

Connecting Rod Journal Diameter 1.9987-1.9994 in

Crankshaft Main Journal Diameter 2.6473-2.6483 in

I'm having a hard time finding the journal widths for the 3400... but since the 3500 crank needs different rods it doesn't matter anymore. But hey, its was the only part of my engine I have not found a stronger replacment for so it's worth consideration.

Comment